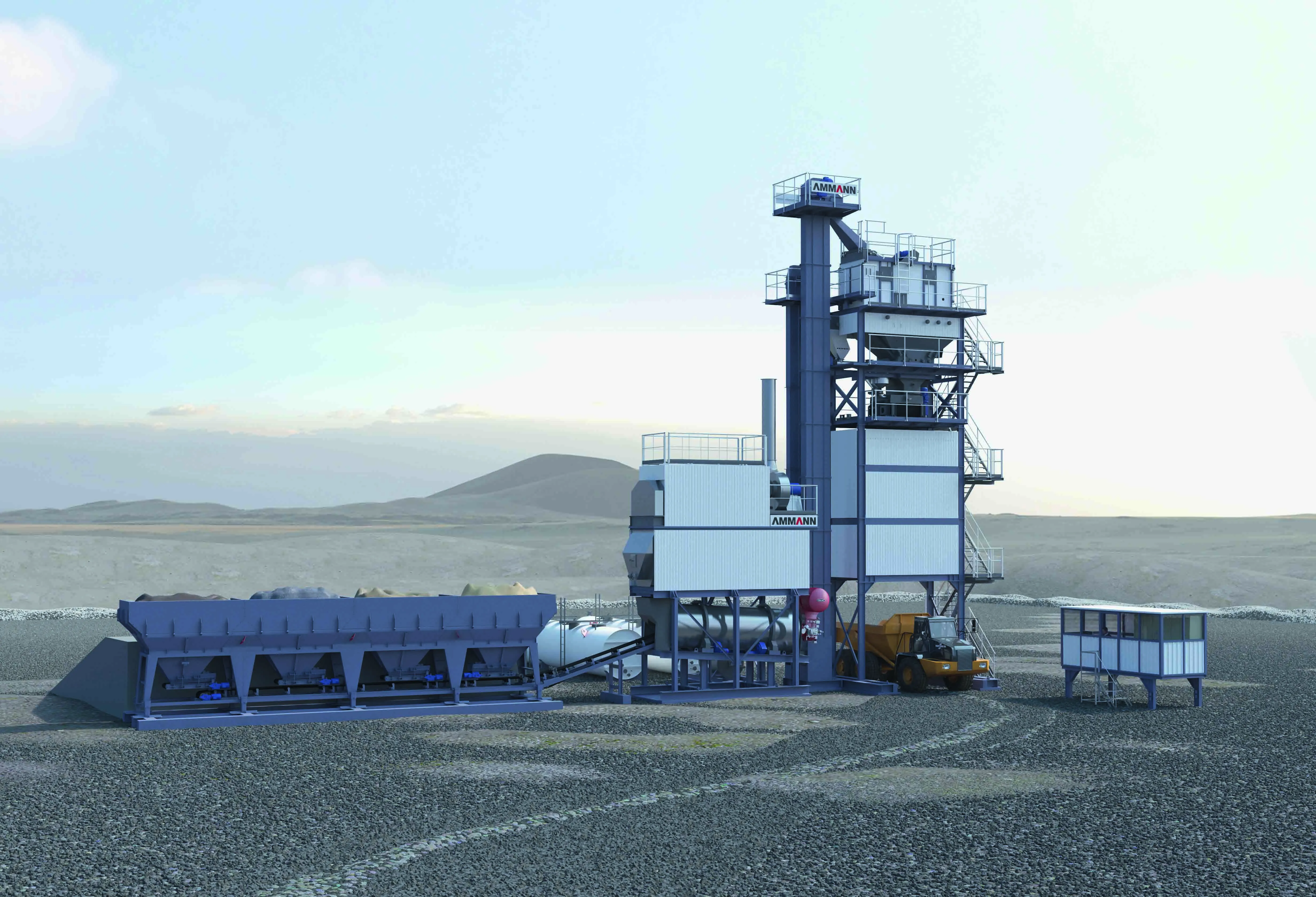

The plant is available with extensions as required for aggregate or cement storage and options also include high-pressure cleaning of the mixer and independent weighing of the individual components for a high output rate.

Due to the adjustable concrete discharge, the concrete can be collected by anything from small trailers right up to large truck mixers.

The customer can select the required quantity of concrete from a range of different material types and from volumes as low as 0.15-2m3. Once the order is placed, the customer’s vehicle is positioned under the plant to receive the delivery. The mixing process is started using a QR-code and within 2-3 minutes the fresh concrete will be delivered directly into the trailer or truck mixer. Because the plant is versatile, it can be used to supply small quantities of concrete for repair purposes and as it is a self-service unit, customers can receive the materials they need at any time of the day or week as required.

To suit the application, the plant has also been designed to be highly mobile, allowing it to be relocated quickly and easily. The unit can be transported on a single truck and has all its components installed inside two containers. Once set up onsite, it requires a space of just 100m2. According to Liebherr, this new plant will allow concrete suppliers to extend their offering to customers by allowing the supply of small quantities of materials 24/7.