A new solution from Schreiner Services allows RFID transponders integrated into Provlies geotextile products to be scanned and identified. The novel geotextile material can be used to repair into cracked roads, where it delays future damage due to its elasticity.

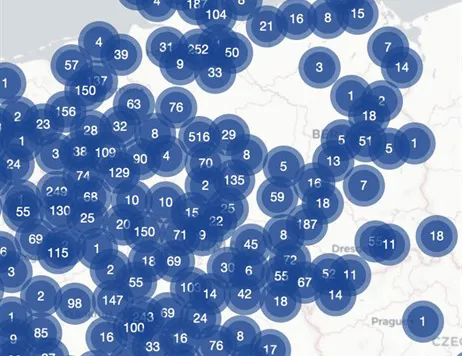

Every 100m an RFID transponder records data relating to traffic count or road condition. Schreiner Services has developed a mobile solution for the Provlies geotextile that enables the readout of the recorded data at speeds of up to 60km/h.

April 1, 2016

Read time: 2 mins

A new solution from Schreiner Services allows RFID transponders integrated into Provlies geotextile products to be scanned and identified. The novel geotextile material can be used to repair into cracked roads, where it delays future damage due to its elasticity.

Every 100m an RFID transponder records data relating to traffic count or road condition. Schreiner Services has developed a mobile solution for the Provlies geotextile that enables the readout of the recorded data at speeds of up to 60km/h.

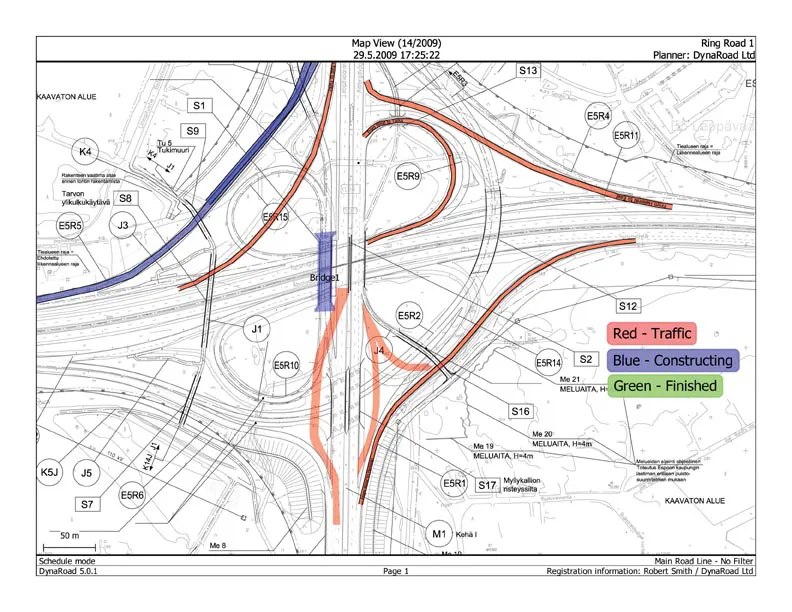

The RFID tags integrated into the nonwoven geotextiles of Provlies are linked with applications such as digital atlases, automatic traffic count, construction journals, sewer network maps and weather information. In addition, modules for condition assessment, construction or construction supervision can be integrated.

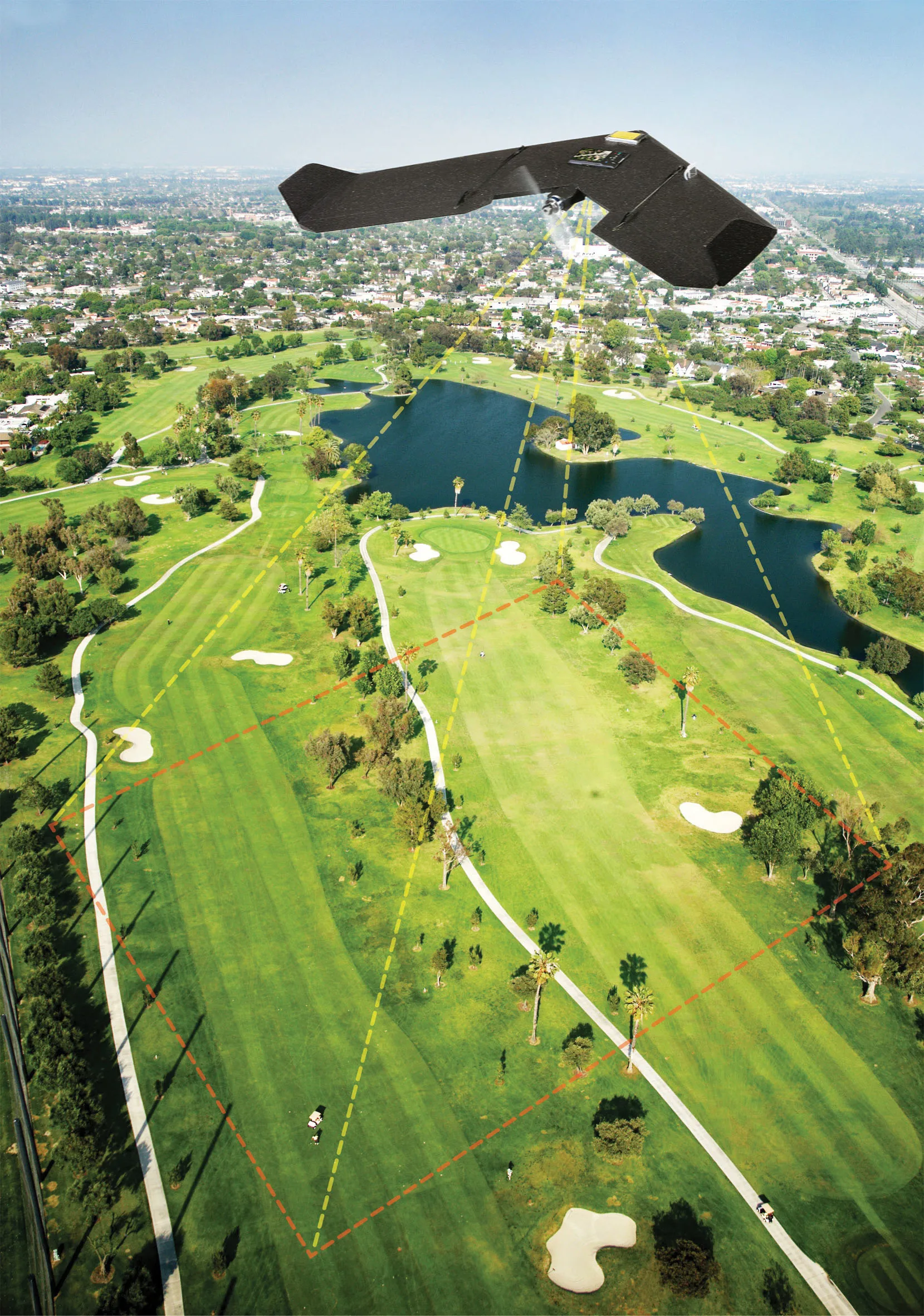

Schreiner has also developed a mobile solution for the easy readout of the RFID tags. Readout is provided via several antennae, which fit into a weather-resistant box together with electronics. The box is mounted to the trailer hitch of a vehicle. The data is radio-transmitted to the computer in the car for evaluation. The collected data gives road maintenance service providers a detailed overview of the road's condition, thus contributing to increasing the service life of reconstructed roads. This helps to reduce costs and guarantees sustainable road construction.

The RFID labels applied directly to the nonwoven material lie at least 4cm under an asphalt surface and offer the road maintenance provider continuous, contactless communication with the road network. The RFID transponders work with ultra-high frequencies and are therefore easily readable even through thick layers of asphalt and concrete. The scanning system can be mounted in a vehicle and enables secure and comfortable readout. The system offers a large range and convenient data transfer, even during a fast drive, according to the firm.

Every 100m an RFID transponder records data relating to traffic count or road condition. Schreiner Services has developed a mobile solution for the Provlies geotextile that enables the readout of the recorded data at speeds of up to 60km/h.

The RFID tags integrated into the nonwoven geotextiles of Provlies are linked with applications such as digital atlases, automatic traffic count, construction journals, sewer network maps and weather information. In addition, modules for condition assessment, construction or construction supervision can be integrated.

Schreiner has also developed a mobile solution for the easy readout of the RFID tags. Readout is provided via several antennae, which fit into a weather-resistant box together with electronics. The box is mounted to the trailer hitch of a vehicle. The data is radio-transmitted to the computer in the car for evaluation. The collected data gives road maintenance service providers a detailed overview of the road's condition, thus contributing to increasing the service life of reconstructed roads. This helps to reduce costs and guarantees sustainable road construction.

The RFID labels applied directly to the nonwoven material lie at least 4cm under an asphalt surface and offer the road maintenance provider continuous, contactless communication with the road network. The RFID transponders work with ultra-high frequencies and are therefore easily readable even through thick layers of asphalt and concrete. The scanning system can be mounted in a vehicle and enables secure and comfortable readout. The system offers a large range and convenient data transfer, even during a fast drive, according to the firm.