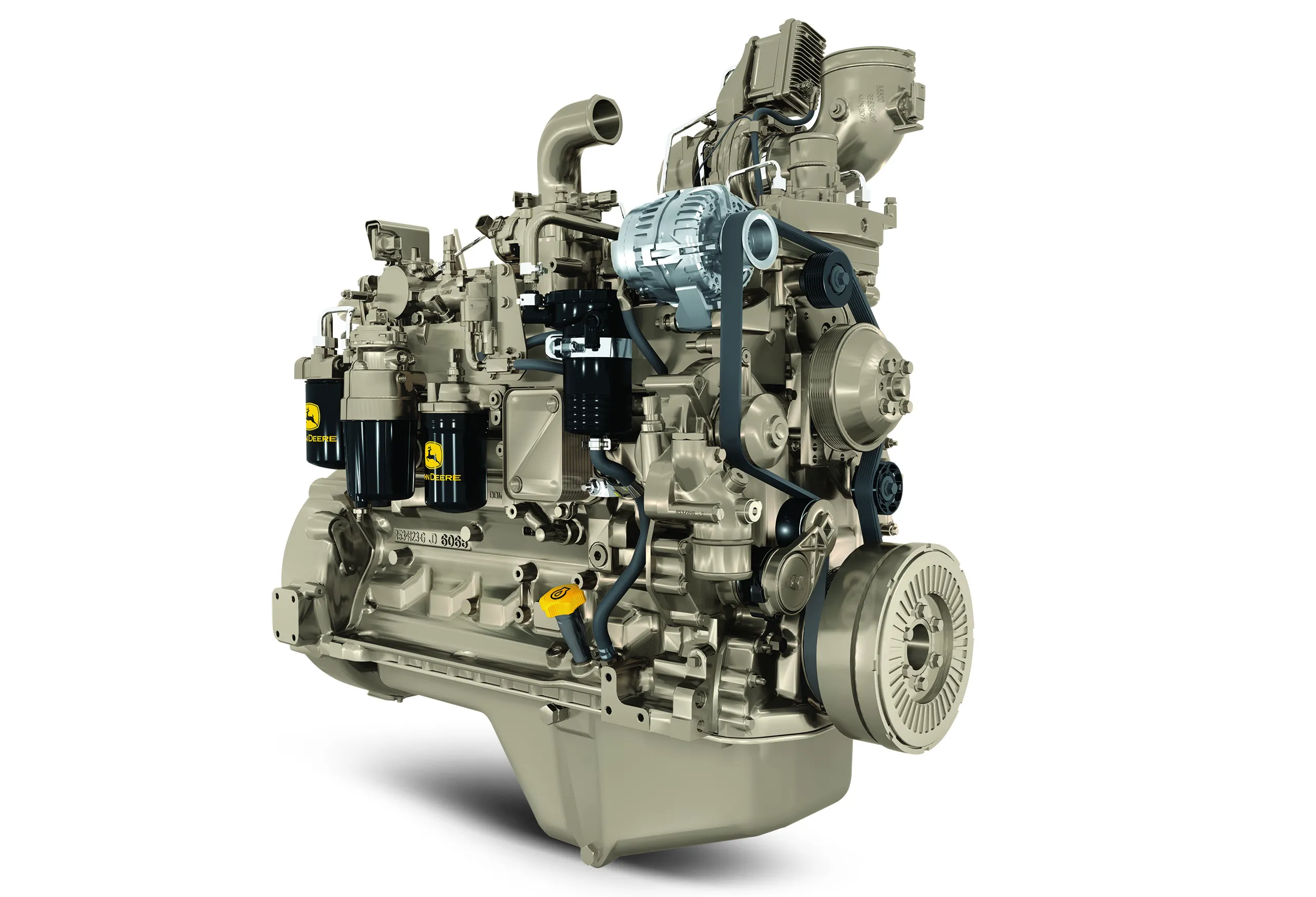

Engine supplier Scania has a full range of Stage V ready engines on offer to machinery OEMs. Based on the firm’s proven on-highway Euro 6 range, the 9-, 13- and 16-litre engines use both a DPF and SCR with an exhaust additive fluid. In-house engine management, including fuel injection, exhaust after treatment, charge air and engine operating temperatures are all taken care of by a control unit mounted on the cool side of the engine. Scania is currently moving to the same DPF and SCR solution for its on-high

January 6, 2017

Read time: 1 min

Engine supplier 759 Scania has a full range of Stage V ready engines on offer to machinery OEMs. Based on the firm’s proven on-highway Euro 6 range, the 9-, 13- and 16-litre engines use both a DPF and SCR with an exhaust additive fluid. In-house engine management, including fuel injection, exhaust after treatment, charge air and engine operating temperatures are all taken care of by a control unit mounted on the cool side of the engine. Scania is currently moving to the same DPF and SCR solution for its on-highway trucks, and can offer construction buyers a Stage V solution well ahead of the 2019 implementation date.