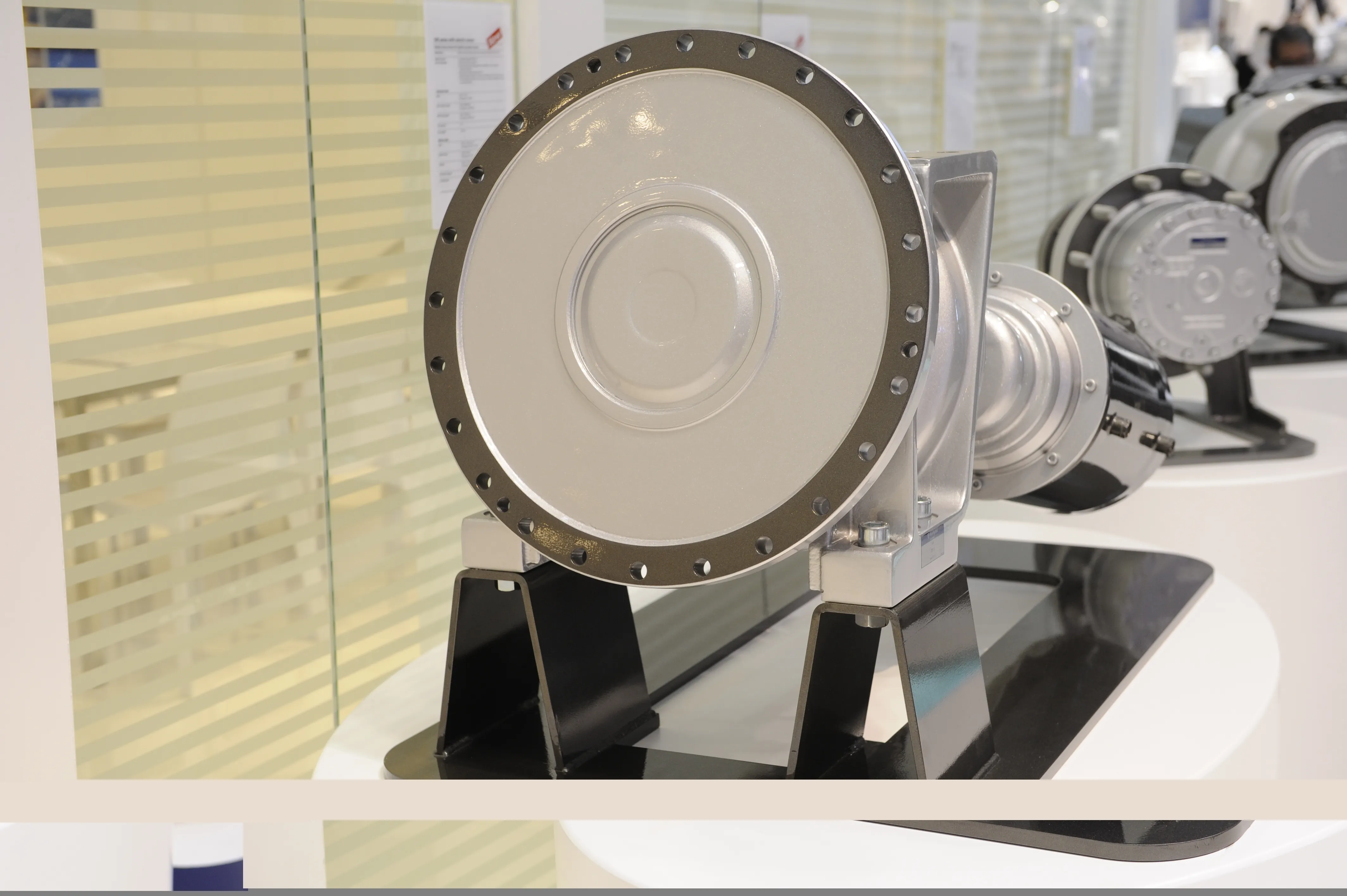

Sandvik unveiled its latest screen at bauma 2014 in Shanghai. The new SK2462 is the latest in the SK&SC range. A modular approach in the range allows flexibility for aggregate producers and quarries. These units facilitate accurate and efficient screening in the secondary and tertiary stages.

The new circular motion screen is 2.4m by 6m and weighs in at 7.3tonnes. Power is provided by a 22kW motor allowing rotation speeds of between 780 and 900pm. It is designed for heavy-duty medium and fine screening applications especially after primary and secondary crushing. Dust encapsulation is incorporated to satisfy clean air regulations.

It can be deployed at incline rates of between 15° and 22° and has an acceleration rate of up to 3.5G. Maximum feed size is 200mm with separation of between 1 and 130mm. Sandvik offer a full range of screening media in polyurethane and other rubber qualities.

Maintenance was a key point in developing Sandvik's new screens to minimise operational downtime. The number of parts has been reduced and bearing lubrication improved. In addition the vibration mechanism can be removed and installed as a fully assembled module.

%$Linker: