Siemens has developed a new cycle detection system that can trigger signalling and be used to monitor user numbers. The novel WiMag Cycle Detection package uses in-ground, low-power, wireless detectors and microwave radar technology to identify and count bicycles of all types, including those made of carbon fibre. The solution complements the company’s existing WiMag, loop and radar detection solutions.

September 15, 2015

Read time: 2 mins

The firm said that the WiMag Cycle Detectors differentiate between cycles and motorised vehicles and can distinguish objects based on their speed. Bicycles do not need to pass directly over the detector in order to be identified according to the company. The system allows road authorities to determine accurately how many cyclists are using a specific route so as to see whether more capacity is required.

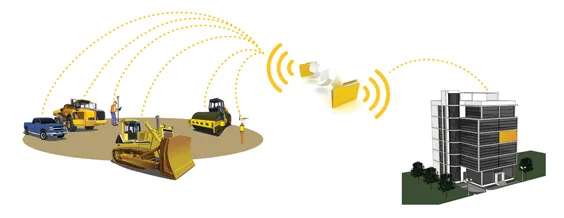

The system uses a low-power wireless transmitter/receiver and a dedicated battery to transmit detection data to an associated access point or repeater. WiMag Cycle Detection can be used to detect the presence of bicycles, provide count information and enable traffic signalling phasing to be tailored based on cycle demand.

The installation of the WiMag Cycle Detection System is simple and requires coring the appropriate diameter hole in the carriageway and fixing the detector in place with a dedicated epoxy resin, eliminating the need for extensive ducts. The system can be used in conjunction with the Siemens WiMag Vehicle Detection System, sharing the same communications infrastructure and using access points and repeaters to establish two-way wireless links to detectors within the system.