The Luxembourg Airport, located in Findel, is a major cargo destination in Europe. Along with ever growing passenger traffic, the airport’s one runway is 4 kilometres long and 60 metres wide—and was in need of complete renovation and repair after 30 years of operation in order for it to meet international standards.

Click here to watch the video

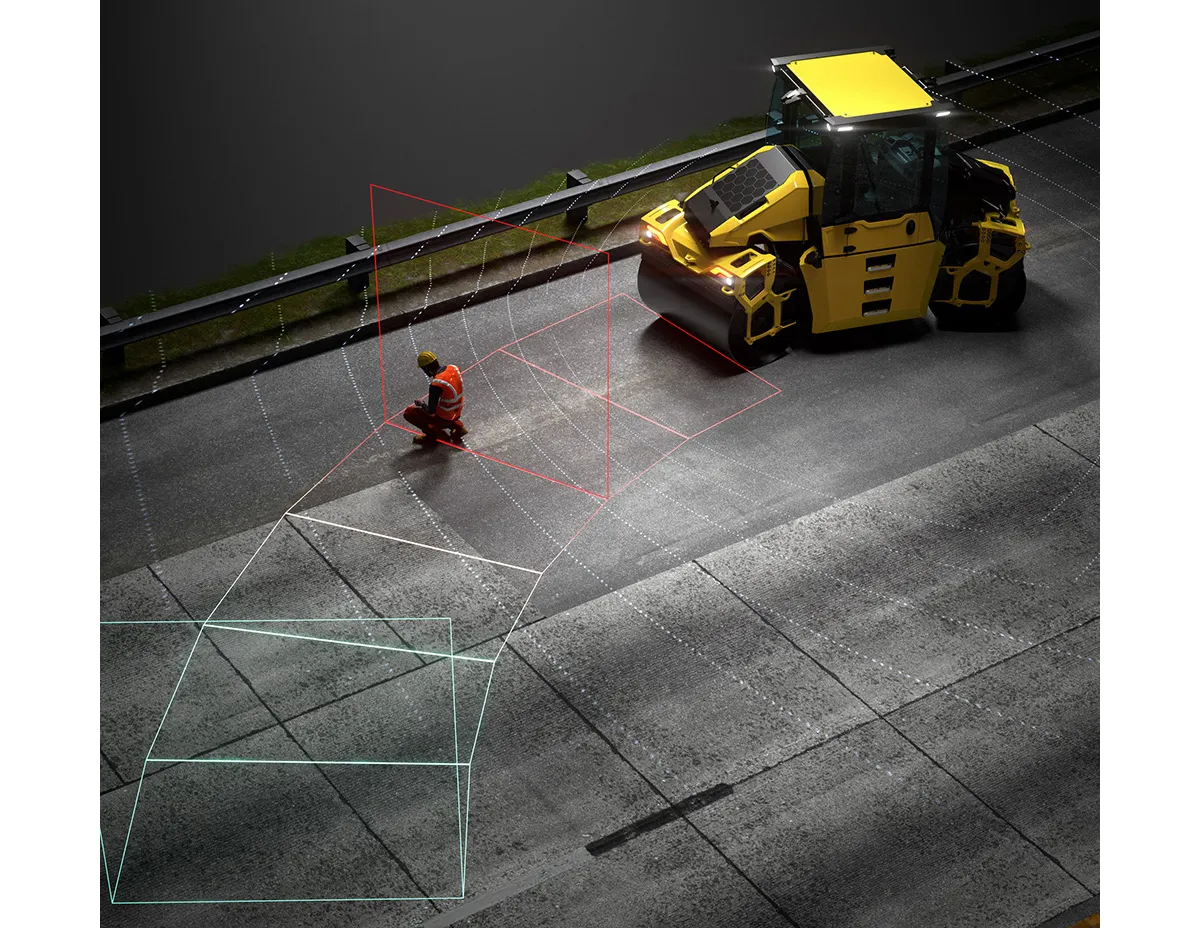

Airport operators needed a way to complete the runway reprofile without disrupting daily scheduled take-offs and landings. With an eye on speed, flexibility and quality, the operators opted to essentially build a new runway with different asphalt layers over the existing one. The idea was that milling machines would rectify the profile of the track while the asphalt pavers would apply the asphalt necessary to reach the desired level each night, reopening each morning for normal airport operations to resume.

Airport operators needed a way to complete the runway reprofile without disrupting daily scheduled take-offs and landings. With an eye on speed, flexibility and quality, the operators opted to essentially build a new runway with different asphalt layers over the existing one. The idea was that milling machines would rectify the profile of the track while the asphalt pavers would apply the asphalt necessary to reach the desired level each night, reopening each morning for normal airport operations to resume.

“It was not possible to carry out this project without 3D machine control, with a classic workflow,” explains Christophe Latteur, with Karp-Kneip Construction. “We knew Trimble equipment and how it worked.” He continues, “Embracing 3D machine guidance—even in this particularly demanding context, everyone knows where he has to go, how he has to get there and what he has to do.”

A single Trimble MT900 Machine Target of the milling machine is supplemented by a Trimble GS420 Machine Control sensor. A manual control of the milled depth makes it possible to check the dimension and to validate the quantities of asphalt to be laid afterwards.

A single Trimble MT900 Machine Target of the milling machine is supplemented by a Trimble GS420 Machine Control sensor. A manual control of the milled depth makes it possible to check the dimension and to validate the quantities of asphalt to be laid afterwards.

It’s a high-precision, highly complex mission with no room for delays—but it worked out. The operation was made possible thanks to a skilled team, 3D machine guidance, state-of-the-art technology from Trimble and the support and training provided by SITECH France, the local Trimble distributor.

Click here to watch the video

Content produced in association with Trimble