Austrian company Rubble Master has added a new flagship model to its crusher range, the RM 120GO, which it says takes it into “a new league.”

Celebrating 25 years in business, the company introduced the new 34tonne tracked mobile impact crusher watched by its founder and CEO Gerald Hanisch.

He said that having passed the 30tonne mark, the machine would “open up a new segment for us”, being capable of processing 350tonnes/hour fed from its 4m³ hopper.

The company also says that its Spec2App, a “grou

April 14, 2016

Read time: 2 mins

Austrian company 747 Rubble Master has added a new flagship model to its crusher range, the RM 120GO, which it says takes it into “a new league.”

Celebrating 25 years in business, the company introduced the new 34tonne tracked mobile impact crusher watched by its founder and CEO Gerald Hanisch.

He said that having passed the 30tonne mark, the machine would “open up a new segment for us”, being capable of processing 350tonnes/hour fed from its 4m³ hopper.

The company also says that its Spec2App, a “ground-breaking” ethos behind a system for configuring RM machines based on their next field of application, extends the product portfolio horizontally. As a result, one RM machine can be used for all applications in the natural rock and recycling industry.

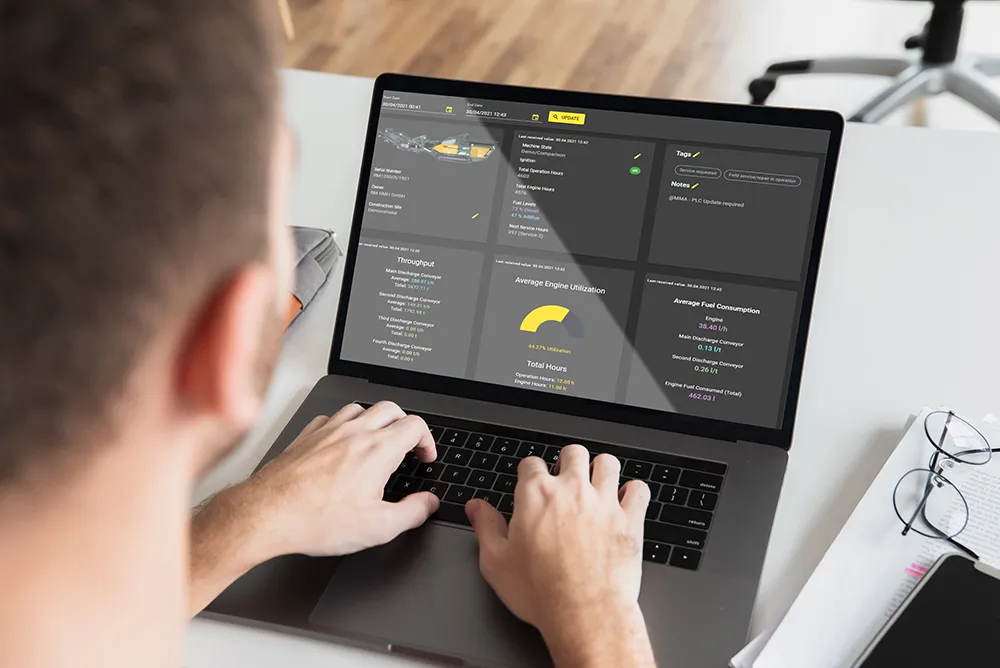

The new generation of mesh deck screens and the hydraulic pivoting refeeding belt are also included in the Spec2App, and the new GO! Smart remote performance optimisation system is an important component.

Rubble Master says that the RM 120GO! can be used to crush a wide range of different materials, and it will be put through its paces in Europe before full introduction next year.

GO! Smart is said to provide important information and advice during operation and ensures efficient maintenance, servicing and monitoring procedures. Mobile devices, including smartphones and tablets, are used to visualise and process the information.

Celebrating 25 years in business, the company introduced the new 34tonne tracked mobile impact crusher watched by its founder and CEO Gerald Hanisch.

He said that having passed the 30tonne mark, the machine would “open up a new segment for us”, being capable of processing 350tonnes/hour fed from its 4m³ hopper.

The company also says that its Spec2App, a “ground-breaking” ethos behind a system for configuring RM machines based on their next field of application, extends the product portfolio horizontally. As a result, one RM machine can be used for all applications in the natural rock and recycling industry.

The new generation of mesh deck screens and the hydraulic pivoting refeeding belt are also included in the Spec2App, and the new GO! Smart remote performance optimisation system is an important component.

Rubble Master says that the RM 120GO! can be used to crush a wide range of different materials, and it will be put through its paces in Europe before full introduction next year.

GO! Smart is said to provide important information and advice during operation and ensures efficient maintenance, servicing and monitoring procedures. Mobile devices, including smartphones and tablets, are used to visualise and process the information.