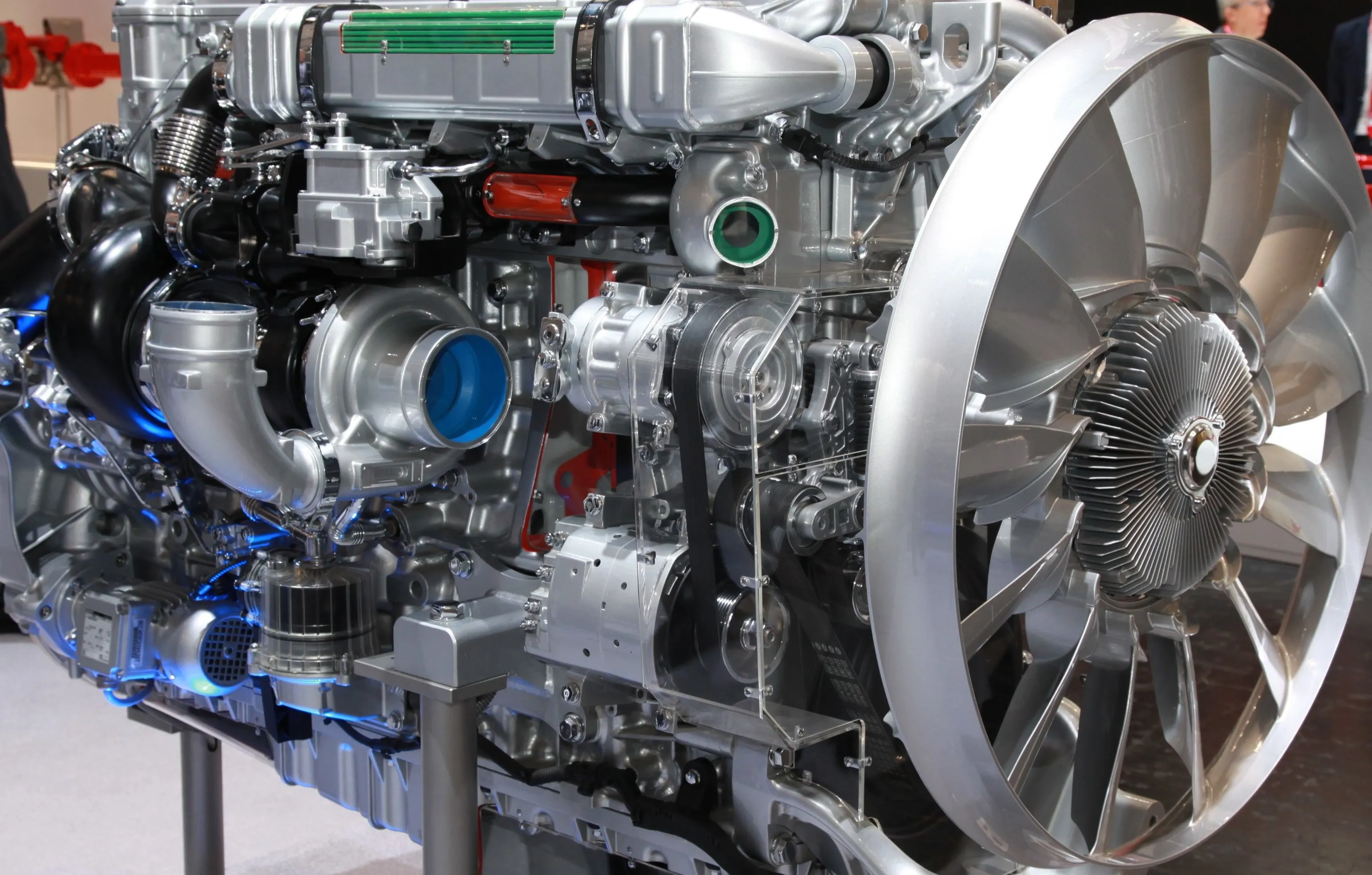

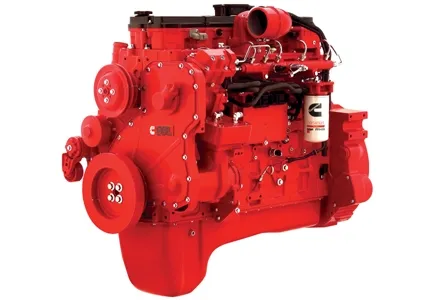

Engine manufacturer MTU, a division of Rolls Royce Power Systems, is using a range of technologies to meet the proposed EU Stage V emissions regulations that are expected in 2019. The company’s 1000-1500 engine ranges, with power outputs of 100-480kW, will be available with both one-box and two-box exhaust after treatment solutions, including diesel particulate filters (DPF) and selective catalytic reduction (SCR) with a diesel exhaust fluid. The engines use Daimler commercial vehicle engines as a base and

January 6, 2017

Read time: 1 min

Engine manufacturer 7648 MTU, a division of Rolls Royce Power Systems, is using a range of technologies to meet the proposed EU Stage V emissions regulations that are expected in 2019. The company’s 1000-1500 engine ranges, with power outputs of 100-480kW, will be available with both one-box and two-box exhaust after treatment solutions, including diesel particulate filters (DPF) and selective catalytic reduction (SCR) with a diesel exhaust fluid. The engines use Daimler commercial vehicle engines as a base and MTU and Daimler will jointly develop them to meet Stage V.

Engines above 500kW are also being developed, in 1600 and 2000 series. These engines comply with US Tier 4 emissions standards and are also being designed to meet EU Stage V.

Engines above 500kW are also being developed, in 1600 and 2000 series. These engines comply with US Tier 4 emissions standards and are also being designed to meet EU Stage V.