RMD Kwikform’s digital assets include apps, product videos, CAD resources and technical data. LocusHUB offers users an evolving library of digital tools to help optimise working processes and improve productivity levels.

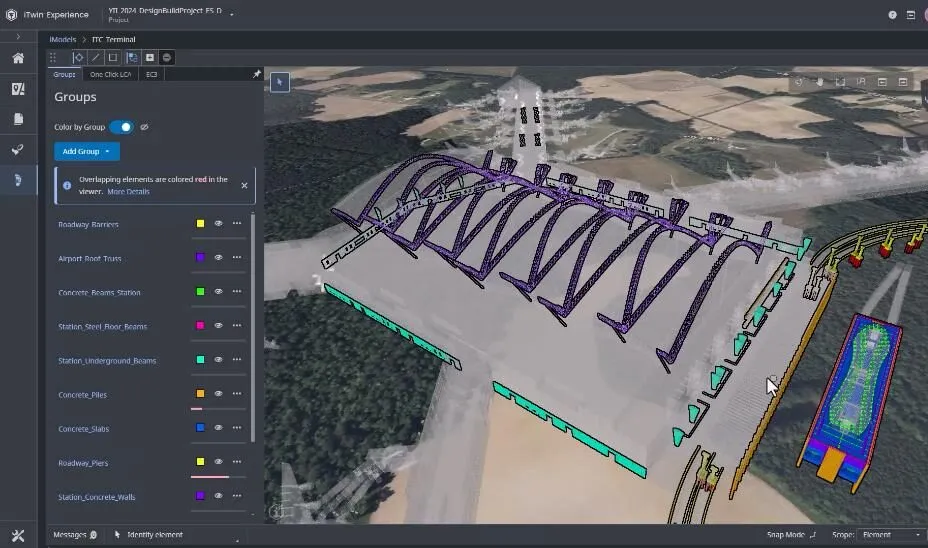

For example, during the design phase, digital construction can help reduce revisions, eliminate redundant conversations between parties and ensure any errors are quickly identified. It can also help improve safety standards and ensure better workforce planning.

Tools on LocusHUB include LocusEye, RMD Kwikform’s 3D visualisation software which offers interactive 3D models of temporary work schemes. RMD said it will provide a vital means of viewing and interrogating a temporary works solution during the pre-tender or build phases of a project.

LocusEye reduces onsite risks, as any potential issues can be quickly seen. Available to download as an app, it helps project teams understand the challenges of a temporary works scheme in greater detail than ever before, explained Matt Wiseman, divisional digital innovation manager at RMD Kwikform.

RMD’s entire catalogue of material handling and guidance notes for its products is stored on LocusHUB, too. Particularly with social distancing guidelines still needing to be followed on construction sites, the material handling guides can help illustrate to users how to best assemble, manoeuvre and dismantle equipment ahead of delivery, to ensure site operatives always stay in line with social distancing measures