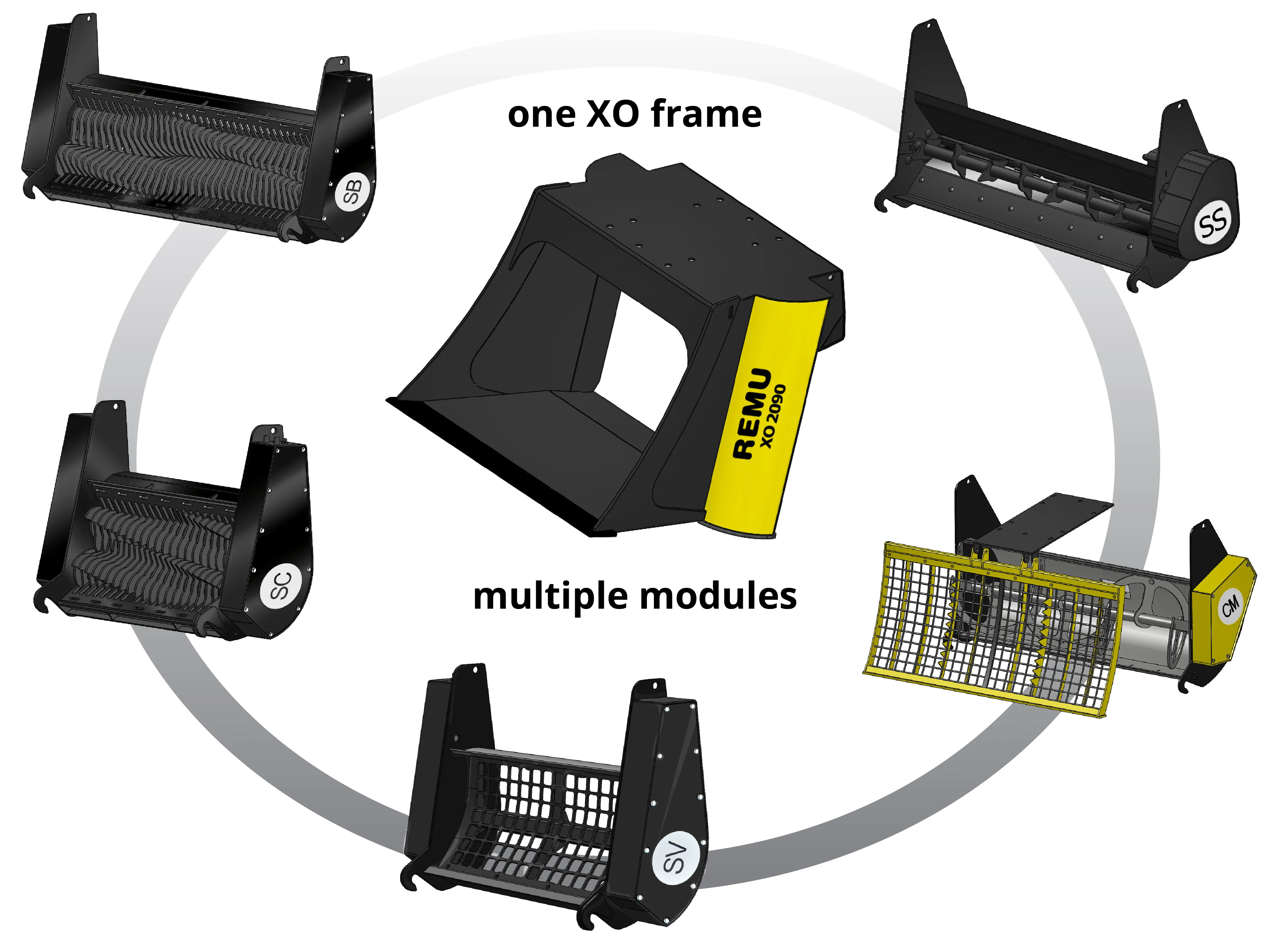

Finnish company REMU has introduced a number of modularly structured Crossover bucket attachments. Crossover buckets have a separate frame structure and exchangeable work module that enables fluent transition from one application to another. By exchanging the work modules for the Crossover frame, the bucket can be transformed into a screening bucket; a crushing bucket; a vibrating screening bucket, or even a concrete mixer and a sand spreading bucket. “Changing the module takes only ten minutes which enabl

March 11, 2016

Read time: 1 min

Finnish company 2405 REMU has introduced a number of modularly structured Crossover bucket attachments.

Crossover buckets have a separate frame structure and exchangeable work module that enables fluent transition from one application to another.

By exchanging the work modules for the Crossover frame, the bucket can be transformed into a screening bucket; a crushing bucket; a vibrating screening bucket, or even a concrete mixer and a sand spreading bucket.

“Changing the module takes only ten minutes which enables contractor to complete the following work stages in an efficient manner,” says REMU.

The Crossover product line includes two sizes of bucket frames: XO 2090 for excavators over 5tonnes and XO 2150 for excavators over 8tonnes.

For both frame sizes there are five different types of work modules available which is said to make Crossover “the most versatile bucket attachment in the market.”

Crossover buckets have a separate frame structure and exchangeable work module that enables fluent transition from one application to another.

By exchanging the work modules for the Crossover frame, the bucket can be transformed into a screening bucket; a crushing bucket; a vibrating screening bucket, or even a concrete mixer and a sand spreading bucket.

“Changing the module takes only ten minutes which enables contractor to complete the following work stages in an efficient manner,” says REMU.

The Crossover product line includes two sizes of bucket frames: XO 2090 for excavators over 5tonnes and XO 2150 for excavators over 8tonnes.

For both frame sizes there are five different types of work modules available which is said to make Crossover “the most versatile bucket attachment in the market.”