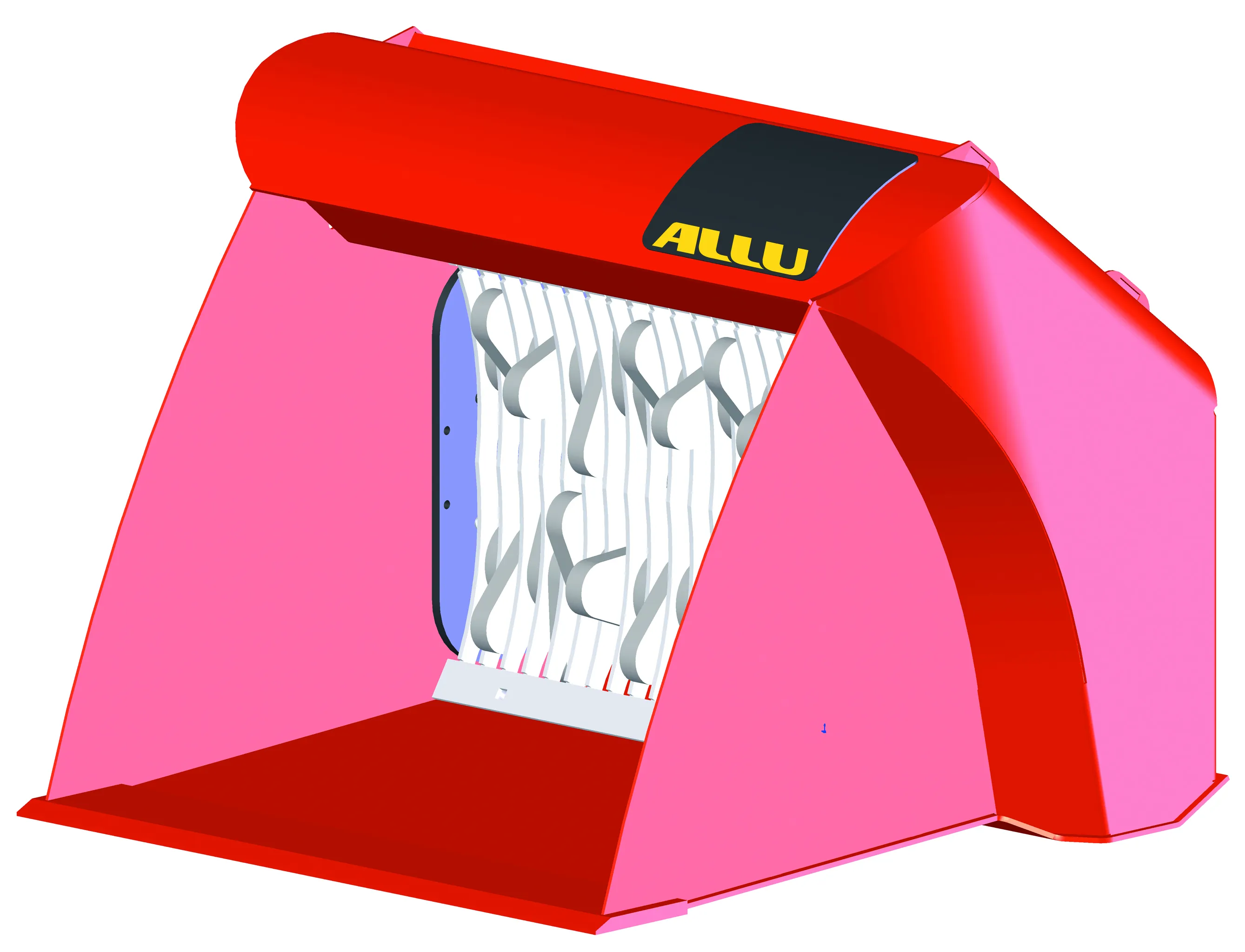

Finnish company Remu is showcasing reinforced screening buckets and screener-crushers for rough conditions, saying that US customers’ wishes have been fulfilled with a series of screening bucket improvements. For example, the models include wear-resistant steel rotors and high-strength wear-resistant Raex steel by Ruukki, which is said to extend the lifespan of machinery while the wear in structural components is decreased and costs are saved.

January 6, 2017

Read time: 1 min

Finnish company 2405 REMU is showcasing reinforced screening buckets and screener-crushers for rough conditions, saying that US customers’ wishes have been fulfilled with a series of screening bucket improvements.

For example, the models include wear-resistant steel rotors and high-strength wear-resistant Raex steel by Ruukki, which is said to extend the lifespan of machinery while the wear in structural components is decreased and costs are saved.

The buckets also have bolt attached comb counter blades and cleaning scrapers and bolted side doors and plugs for greasing in the EE series.

REMU manufactures screening buckets, plants and big floats and amphibious excavators in Southern Ostrobothnia, Ähtäri, Finland, where it has had business premises since 1997. About 90 % of its turnover comes from export.

www.remu.fi

For example, the models include wear-resistant steel rotors and high-strength wear-resistant Raex steel by Ruukki, which is said to extend the lifespan of machinery while the wear in structural components is decreased and costs are saved.

The buckets also have bolt attached comb counter blades and cleaning scrapers and bolted side doors and plugs for greasing in the EE series.

REMU manufactures screening buckets, plants and big floats and amphibious excavators in Southern Ostrobothnia, Ähtäri, Finland, where it has had business premises since 1997. About 90 % of its turnover comes from export.

www.remu.fi