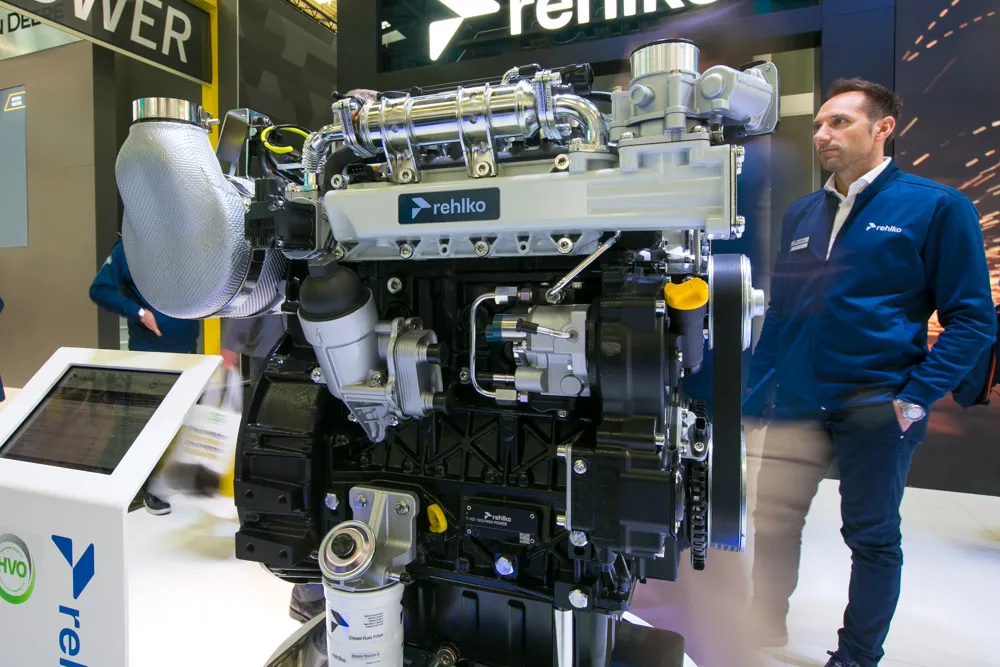

Rehlko’s new KDI 1903TCR engine packs a big punch in a compact package, delivering 50kW of power and 250Nm of torque with three cylinders.

“Our mantra is power density and torque density,” says Massimiliano Bonnani, general manager – product strategy at Rehlko.

“We wanted to provide a three-cylinder engine capable of this level of power to meet the need of our customer to deliver more productivity within the same machine frame.”

The KDI range includes three-cylinder 1.9litre engines which deliver a power output of 42kW and 225Nm torque and four-cylinder 2.5litre engines which deliver 56kW and 315Nm torque. The KDI 1903TCR sits in between the two.

The new engine would be suited to a wide range of construction equipment such as small excavators, skid steers, telehandlers or pumps.

“The high power and torque densities mean that the machine can do more work within the same time window, and with more efficient fuel consumption,” says Bonnani.

The KDI 1903 TCR incorporates Rehlko’s diesel particulate filter (DPF) technology, engineered to meet EU Stage V emission regulations.

The DPF enables efficient automatic regeneration, even at low rpm, says Rehlko. The engine can also run on hydrotreated vegetable oil (HVO) if required to reduce emissions and its carbon footprint in operation.