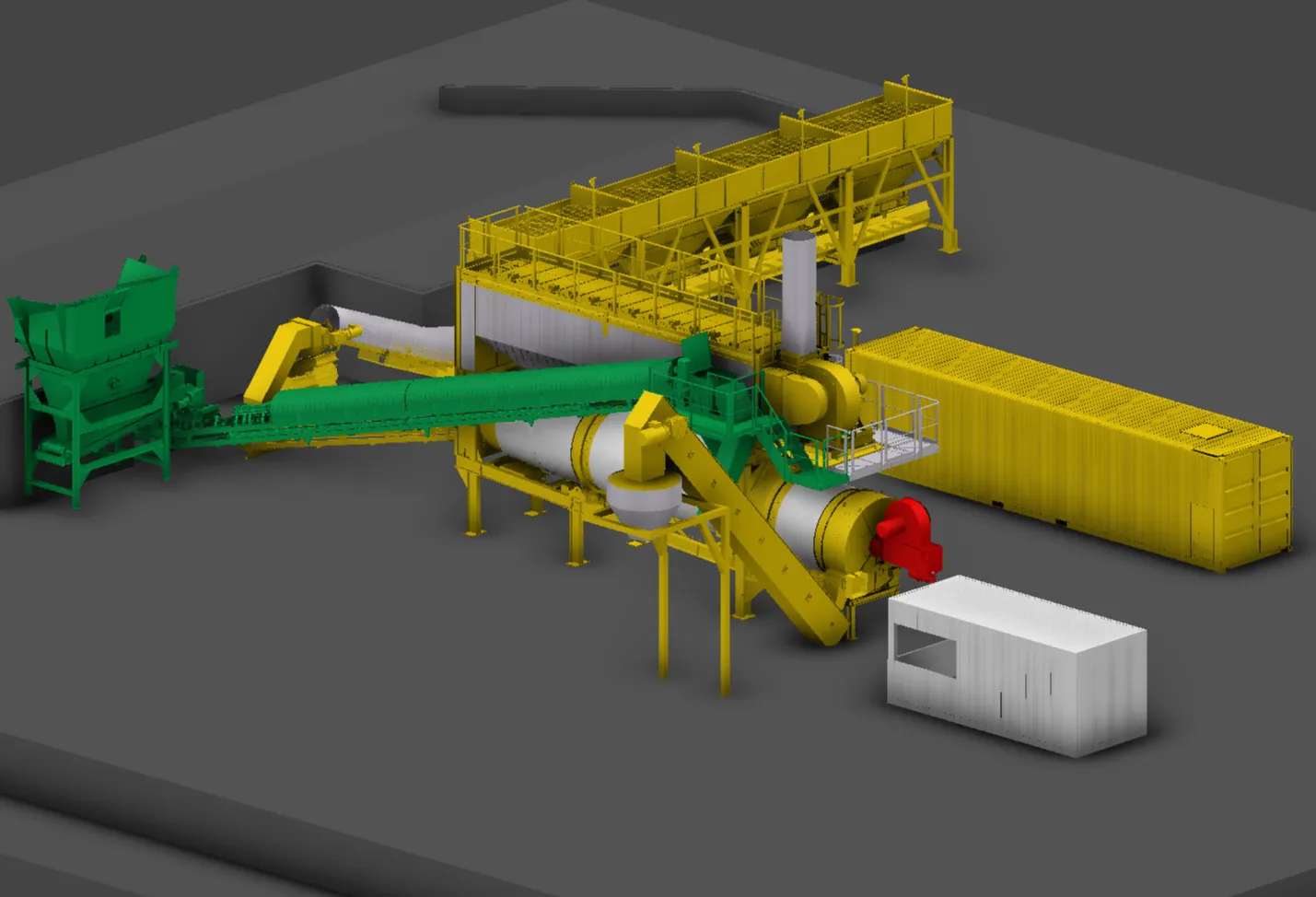

A retrofit solution has been installed at an existing asphalt mixing plant in Nentershausen/Hesse. The REVOC system is an innovative technology developed by Benninghoven delivering more sustainable asphalt production.

The TBA plant from Benninghoven, built in 2007, is located on the site of a basalt quarry and produces 80,000-100,000tonnes of asphalt/year for motorways, roads, and infrastructure projects. To enable more sustainable asphalt production in the future, the plant operator opted to retrofit the existing plant with an emissions control package.

“We chose the REVOC system because it enables us to comply with total carbon (Ctot) emission standards, even with the addition of a high proportion of reclaimed asphalt pavement,” explained Peter Bach, CEO of WWA Westerwald Asphalt.

The patented technology has allowed the plant operator to increase the maximum feed rate of reclaimed asphalt pavement (RAP) from the previous 30–40% to 50%, while reducing Ctot emissions by more than 50%. Initial experience with the retrofitted plant is positive and the use of this system also safeguards the long-term viability of the plant.

Sustainability in asphalt production is determined by two key factors: the ability to increase the RAP feed rate; re-using reclaimed material in a constructive way. The higher the RAP feed rate, the less fresh bitumen is needed, which cuts the carbon footprint. However, it is essential that the strict Ctot threshold values of <50 mg/m³ stipulated in Germany’s official regulations on air quality, ‘TA-Luft’, are fulfilled.

Although reclaimed asphalt pavement (RAP) can already be fed into the production process using established cold or hot recycling technologies, the total carbon emissions are higher. When reclaimed asphalt is heated, part of the Ctot concentration evaporates out of the bitumen contained in the recycling material. Ctot possesses a higher greenhouse gas potential than CO₂, and is a hazard to health in higher concentrations.

In the past, the resolution of the conflict between high RAP feed rates and assuring sustainability in the production process was difficult. Using technology like the REVOC system, these two aspects can now be reconciled: reducing Ctot emissions by up to 50% and realising higher RAP feed rates of up to 60%.

Fumes generated in the mixer of the asphalt mixing plant are extracted at source and passed to the REVOC system for thermal processing. This allows the plant operator to add a higher proportion of RAP to the mixing process without exceeding stipulated threshold values. The method conserves primary resources and also cuts production costs.

The entire project was closely monitored from the start – on-site, by telephone, or by telemaintenance. This included, above all, regular measurement of the emission values and fine tuning of the plant on the basis of the results. The results exceeded expectations with respect to emission reduction and were corroborated by independent measurements.

Improved plant performance, high RAP feed rates and reduced emissions mean that existing plants with technology such as the REVOC system can meet future challenges when tougher legislation is introduced. And emissions control equipment such as this can also be fitted to existing plants from other manufacturers.