The recent Conexpo 2014 exhibition in Las Vegas was the scene of many new product introductions and developments, which manufacturers have been spending enormous amounts on developing in recent years. Two key areas of technological development stand out from what was unveiled; diesel engine advances, and innovations in machine control systems.

May 2, 2014

Read time: 2 mins

The recent Conexpo 2014 exhibition in Las Vegas was the scene of many new product introductions and developments, which manufacturers have been spending enormous amounts on developing in recent years. Two key areas of technological development stand out from what was unveiled; diesel engine advances, and innovations in machine control systems.

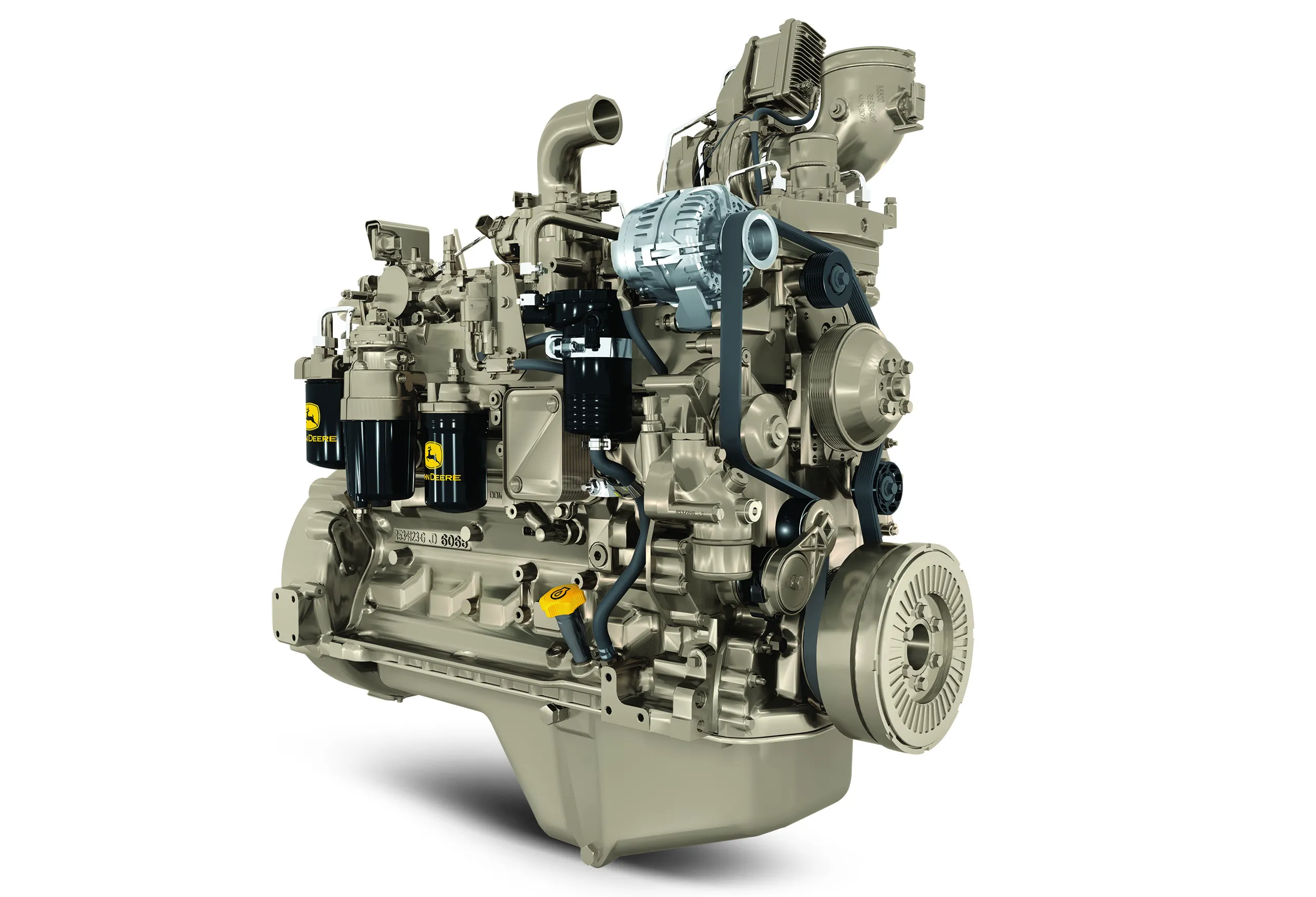

This year has seen the roll-out of the first tranche of Tier 4 Final/Stage IV emissions compliant diesels for off-highway machines, the culmination of a massive period of technological development by engine manufacturers. Thanks to this process, new diesels are cleaner and more fuel-efficient than ever before. In fact when the new engines are running in some polluted urban areas, it is likely that the exhaust gases from a Tier 4 Final diesel will actually be cleaner than the inlet air.

While these new generation engines are more expensive than before, the fuel savings will help cushion the increased purchase costs over the longer term for users. For the moment at least the low emission engines will only be for highly regulated markets such as North America and Europe. The availability of high quality, low sulphur fuel is crucial for all but a few of these diesels and these fuels are only at present available in developed markets. However that will change and the Chinese authorities for one are looking to the future, with plans in hand to introduce Tier 4 Final/Stage IV compliant engines in the coming years in a bid to help reduce airborne pollution in major cities.

Meanwhile, machine control technologies are proliferating in the construction sector. The technology pioneers,265 Leica Geosystems, 342 Topcon and 2122 Trimble, have been continuing to expand their portfolios, while other firms have also entered this market segment. And it is noticeable too how machine control technologies are gaining broader industry acceptance as an understanding of the benefits grows, and these systems are now also being utilised by much smaller contractors than in the past.

Clearly, the tools for more efficient construction operations are now more widely available, and these are also being used. However, questions have to be asked over how much investment in innovation has been focussed on meeting the diesel emissions reduction targets and at what expense to other technology areas?

This year has seen the roll-out of the first tranche of Tier 4 Final/Stage IV emissions compliant diesels for off-highway machines, the culmination of a massive period of technological development by engine manufacturers. Thanks to this process, new diesels are cleaner and more fuel-efficient than ever before. In fact when the new engines are running in some polluted urban areas, it is likely that the exhaust gases from a Tier 4 Final diesel will actually be cleaner than the inlet air.

While these new generation engines are more expensive than before, the fuel savings will help cushion the increased purchase costs over the longer term for users. For the moment at least the low emission engines will only be for highly regulated markets such as North America and Europe. The availability of high quality, low sulphur fuel is crucial for all but a few of these diesels and these fuels are only at present available in developed markets. However that will change and the Chinese authorities for one are looking to the future, with plans in hand to introduce Tier 4 Final/Stage IV compliant engines in the coming years in a bid to help reduce airborne pollution in major cities.

Meanwhile, machine control technologies are proliferating in the construction sector. The technology pioneers,

Clearly, the tools for more efficient construction operations are now more widely available, and these are also being used. However, questions have to be asked over how much investment in innovation has been focussed on meeting the diesel emissions reduction targets and at what expense to other technology areas?