For one of the largest road infrastructure projects in Belgium, REBLOC, along with its local partner De Bonte Group, is providing free-standing concrete safety barriers with integrated noise barrier panels.

The solution is for the Oosterweel Link – Right Bank R1 – E19 project, around Antwerp. Rebloc was commissioned by TM ROCO, an association of Belgian construction companies and managed by LANTIS - set up by the Flemish government to ensure the smooth running of the Oosterweel Link project.

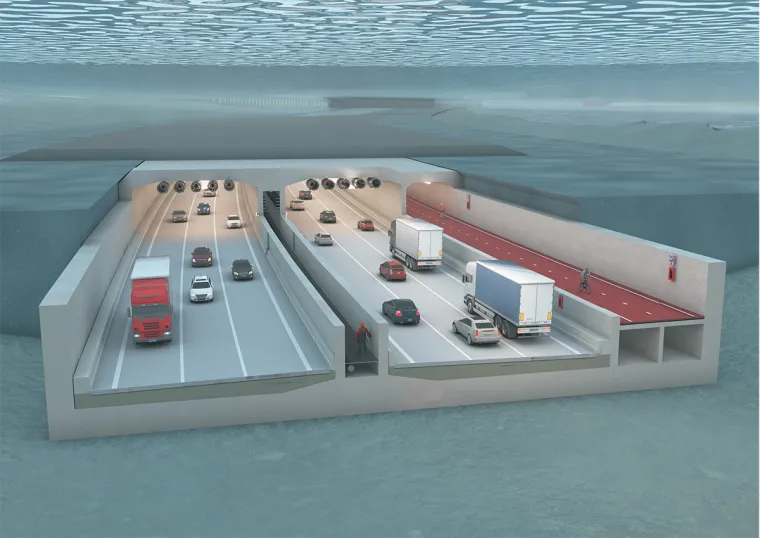

Oosterweel Link is a 15km motorway that will complete the city’s R1 ring road. Construction started in 2018 with all work on the ring road set for completion in 2030. The Antwerp ring road is a key part of the Trans-European Transport (TEN-T) Core Network, a European Union cross-border initiative to enhance major road and rail routes.

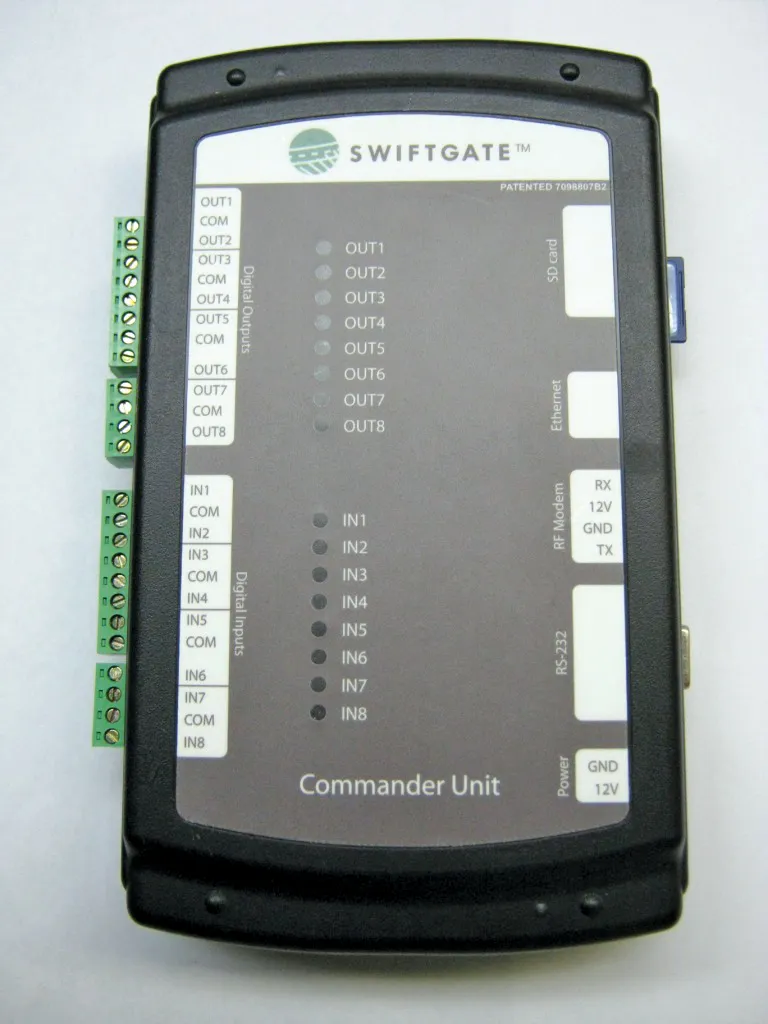

The barrier system from REBLOC is 1.3km in length and includes 5,300m² of REBLOC NBL100X_400_5 barrier, installed between the end of May and mid-June as a temporary sound barrier during construction works.

The construction of a conventional noise barrier is often complicated by various ground and underground installations, such as cables, drainage systems and various pipelines. But REBLOC offers free-standing concrete safety barriers with integrated noise barrier panels. This combination of noise and safety barrier is tested according to EN 1317-2 to meet the required safety and quality standards in Europe.

The noise barrier itself is tested for noise protection in accordance with EN 1793. This space-saving system offers solutions for containment levels H2 and H4b for total heights from 2-6m and above at a very slim overall width. Thanks to this combined system, REBLOC says that the noise barrier can be placed closer to the noise source, resulting in reduced height or an improved noise protection effect. Also, due to the system’s modular design, various highly absorbent panels made of wood-concrete, aluminum or acrylic glass can be combined to allow for numerous architectural design options.

REBLOC‘s space-saving systems leave more room for traffic lanes. The noise barrier can be moved quickly and easily - a great advantage for temporary application or when future road layout changes are planned.