Pavement preservation contractor Innovative Roadway Solutions joined forces with equipment supplier Neal Manufacturing to create a new system for applying Onyx, a frictional mastic surface treatment produced by Ingevity, which has become popular with several Departments of Transport (DoTs) in the US.

The high proportion of aggregate required for Onyx meant that Innovative Roadway Solutions’ usual pumps were not powerful enough and suffered from clogging. “Using Onyx with a traditional pump system results in a lot of unnecessary downtime,” says Kevin King, president of Innovative Roadway Solutions. “Asphalt maintenance has a very limited season — only about seven months in some of the states we work in — so we need to make every minute count.”

As more DoT specifications started to call for Onyx, Innovative Roadway Solutions worked with Neal Manufacturing, part of Blastcrete Equipment, to upgrade their existing equipment with more reliable hydraulic piston pumps.

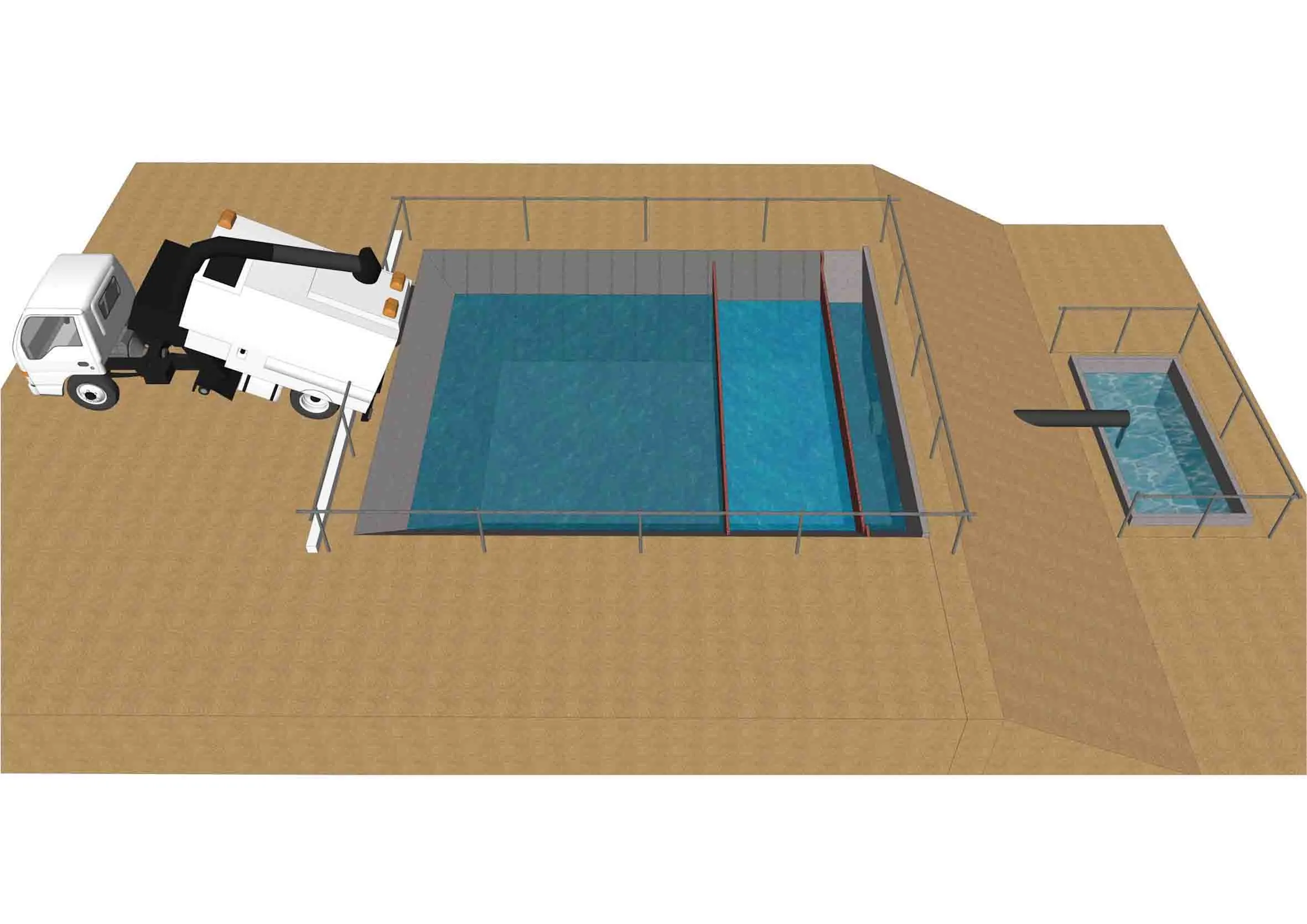

According to Neal, its heavy-duty aggregate pump (HDP) offers the fastest transfer rate on the market, up to 11.4litres/second with enough pressure to move mixtures with up to 1.2kg of sand/litre. The contractor also bought a new 11,356litre truck from Neal Manufacturing, equipped with the HDP.

Neal Manufacturing also developed a bespoke metering system which allowed Innovative Roadway Solutions to demonstrate that it was meeting the application rates required by the DoT’s specifications. The system combines four load cells at the corners of the tank and a distance measuring device to provide an application rate.

Onyx was introduced in the US in 2012. As well as improving the microtexture of the road surface, the product increases durability and restores the pavement colour to black, improving its appearance and giving safety benefits. Since 2017, Innovative Roadway Solutions has completed 25 contracts where Onyx was specified.

“Onyx bridges the gap between a fog seal and slurry seal, allowing us to offer customers another solution that would extend the life of their road surface without breaking the bank,” said King.