Prolec demonstrated its Prolec Machine Engine (PME) and its Prolec Application Suite (PAS) at the first ever Plantworx exhibition near Coventry, central England.

Knowing the real-time position of machines is a core requirement in the safety and machine control industry. Where many solutions are application or task specific, PME takes machine data and makes it generic regardless of the task required. It is said to be a highly configurable and responsive system that can be tailored to any requirement. It i

August 27, 2013

Read time: 2 mins

Prolec demonstrated its Prolec Machine Engine (PME) and its Prolec Application Suite (PAS) at the first ever Plantworx exhibition near Coventry, central England.

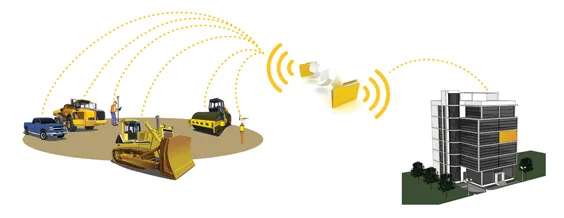

Knowing the real-time position of machines is a core requirement in the safety and machine control industry. Where many solutions are application or task specific, PME takes machine data and makes it generic regardless of the task required. It is said to be a highly configurable and responsive system that can be tailored to any requirement. It is also easily upgradable to incorporate further functions simply and quickly through simple software changes.Designed to combine data from any construction plant that requires load or reach measurement, or control, it provides a modular, integrated system to control both safety and machine guidance functions. This means the installation of one system where previously multiple systems would have been needed.

PAS is

Gary Tuffy, Director of Sales and Marketing, was very impressed with