March 31, 2025

Read time: 1 min

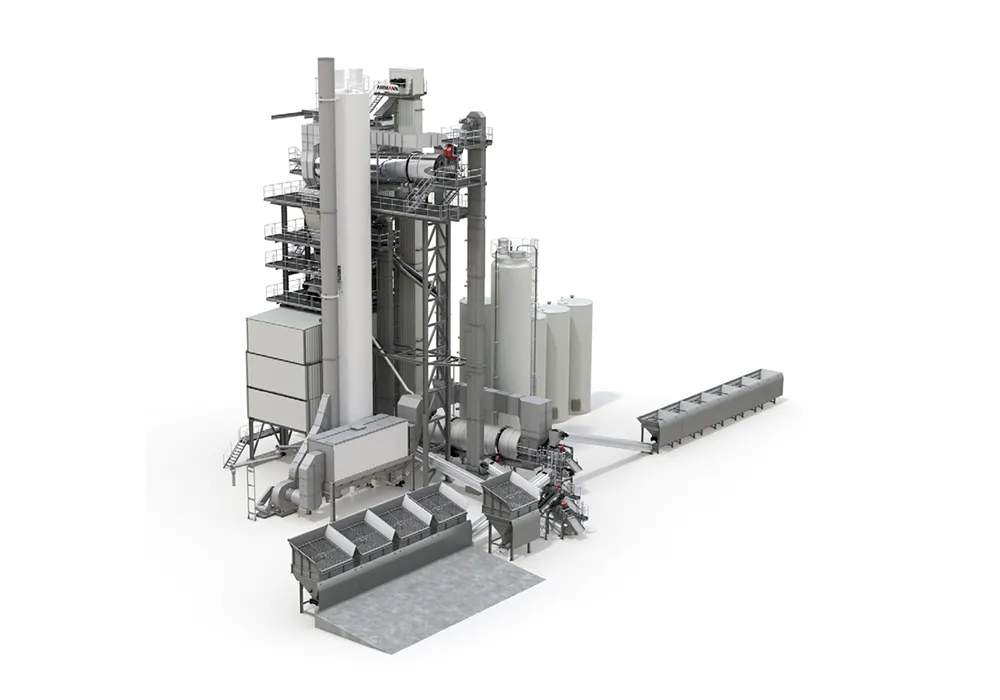

The High Recycling Technology (HRT) Asphalt Batch Plant is a premium Ammann plant, with advanced technologies. It can incorporate up to 100% RAP with extremely low energy consumption and emissions.

The double-drum system combines a virgin aggregate drum with either an RAH60 or RAH100 recycling drum. Indirect, gentle heating reduces fuel burn and emissions. Heat distribution is more homogenous, too, which prevents sticking – as does the vertical flow.

The HRT ABPseries delivers an impressive output ranging from 240-400tonnes/hour, ensuring high-volume production is available for large-scale projects.

Importantly, the HRT is engineered to seamlessly integrate new future technologies.