Among the three new machines from mobile crushing and screening equipment manufacturer Powerscreen is the Premiertrak 300 jaw crusher.

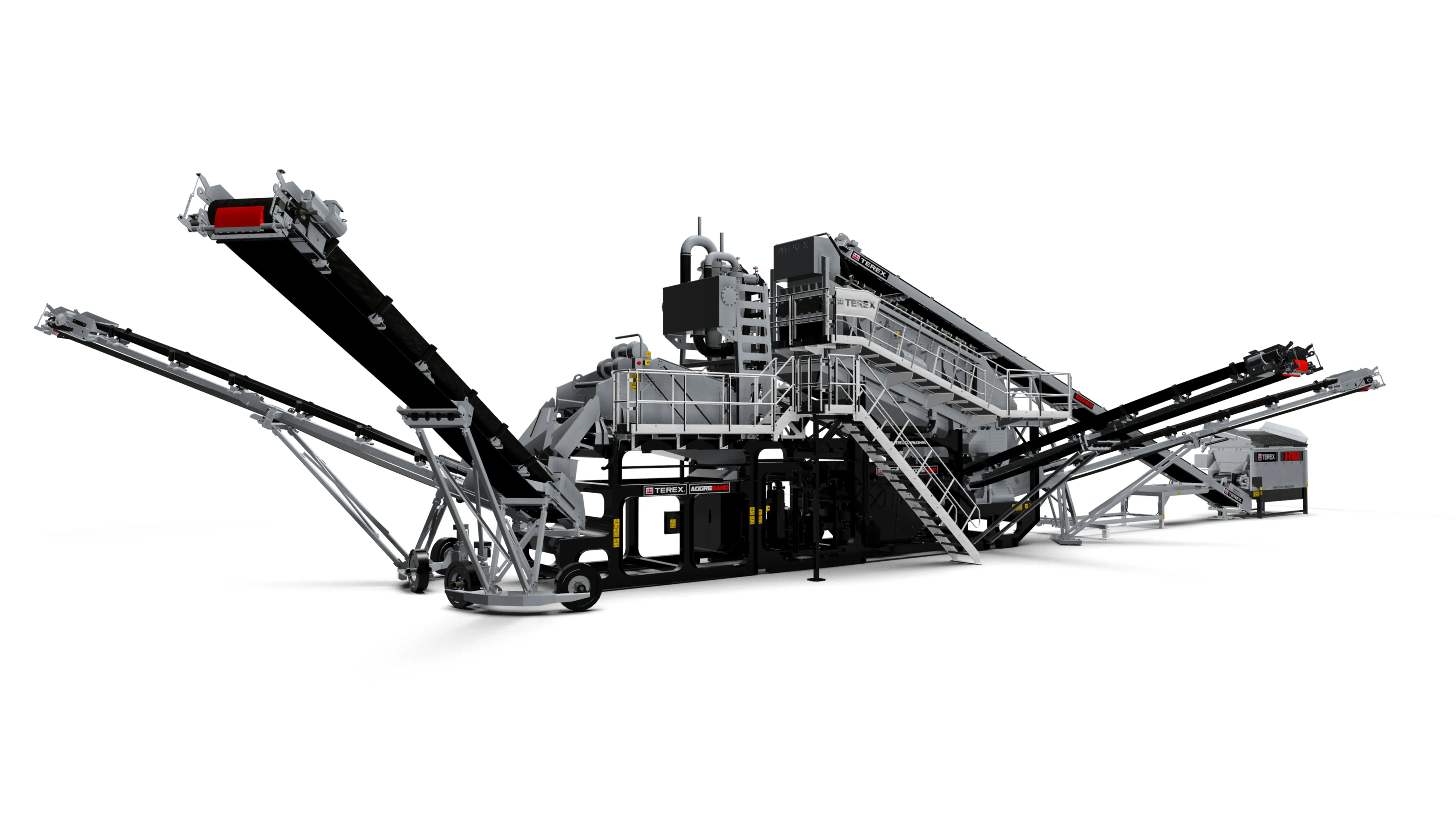

All the machines showcase the rugged new look from Powerscreen, which maintains the traditional Powerscreen green colour while adopting a dark grey colour on the chassis and conveyors. The new paint scheme provides an updated, modern look to the machines, says Powerscreen.

The Premiertrak 300 jaw crusher features the new hydrostatic drive system option allowing it to rever

January 27, 2014

Read time: 2 mins

Among the three new machines from mobile crushing and screening equipment manufacturer 2991 Powerscreen is the Premiertrak 300 jaw crusher.

All the machines showcase the rugged new look from Powerscreen, which maintains the traditional Powerscreen green colour while adopting a dark grey colour on the chassis and conveyors. The new paint scheme provides an updated, modern look to the machines, says Powerscreen.

The Premiertrak 300 jaw crusher features the new hydrostatic drive system option allowing it to reverse and unblock or run continuously in reverse for asphalt applications. It is designed to run at low engine rpm resulting in excellent fuel efficiency and low noise emissions, ideal for urban sites, says Powerscreen.

The machine features a vibrating grizzly feeder (VGF) set with 50mm bofor bar on the top deck and 30mm mesh on the bottom. The closed side setting (CSS) can be set to 40mm while running in both asphalt and recycled concrete applications.

Powerscreen says that other benefits include large clearances in the bypass chute to improve material flow and reduce the chance of blockages in sticky material; a large under crusher clearance and full tunnelling to reduce the chance of blockage due to re-bar build up, and a hydraulically lowering conveyor that offers excellent access to reduce downtime should a blockage occur.

Rapid set-up times are possible with all folding done hydraulically and no need to work at height so the machine can be moved quickly.

Control is via an easy to use PLC screen control system. Jaw speed and CSS can be changed by a single button which allows the machine to be adjusted to suit the application quickly with no tools required.

%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 12748 0 oLinkExternal www.Powerscreen.com Powerscreen web false /EasySiteWeb/GatewayLink.aspx?alId=12748 false false %>

All the machines showcase the rugged new look from Powerscreen, which maintains the traditional Powerscreen green colour while adopting a dark grey colour on the chassis and conveyors. The new paint scheme provides an updated, modern look to the machines, says Powerscreen.

The Premiertrak 300 jaw crusher features the new hydrostatic drive system option allowing it to reverse and unblock or run continuously in reverse for asphalt applications. It is designed to run at low engine rpm resulting in excellent fuel efficiency and low noise emissions, ideal for urban sites, says Powerscreen.

The machine features a vibrating grizzly feeder (VGF) set with 50mm bofor bar on the top deck and 30mm mesh on the bottom. The closed side setting (CSS) can be set to 40mm while running in both asphalt and recycled concrete applications.

Powerscreen says that other benefits include large clearances in the bypass chute to improve material flow and reduce the chance of blockages in sticky material; a large under crusher clearance and full tunnelling to reduce the chance of blockage due to re-bar build up, and a hydraulically lowering conveyor that offers excellent access to reduce downtime should a blockage occur.

Rapid set-up times are possible with all folding done hydraulically and no need to work at height so the machine can be moved quickly.

Control is via an easy to use PLC screen control system. Jaw speed and CSS can be changed by a single button which allows the machine to be adjusted to suit the application quickly with no tools required.

%$Linker: