Machine control technologies are increasingly popular in the concrete slipforming sector according to Power Curbers, while the firm also continues to broaden its array of customer options. Stephen Bullock, vice president of sales and marketing at Power Curbers said, “Stringless is really taking off and even in the last 6-8 months demand has increased drastically. Half of the 5700-Cs we’re quoting for are for stringless operation. It’s growing across the industry.”

January 6, 2017

Read time: 2 mins

Machine control technologies are increasingly popular in the concrete slipforming sector according to 307 Power Curbers, while the firm also continues to broaden its array of customer options. Stephen Bullock, vice president of sales and marketing at Power Curbers said, “Stringless is really taking off and even in the last 6-8 months demand has increased drastically. Half of the 5700-Cs we’re quoting for are for stringless operation. It’s growing across the industry.”

He added that the use of stringless systems is by no means limited to the larger contractors for use on large highway jobs either. He said, “It’s for sub-contractors now as well.”

The firm recently held a demonstration event for its machines that highlighted that working benefits of using stringless systems. The invitees included a diverse array of contractors ranging from small specialist firms right up to larger companies. Bullock said that the customer response to the demonstration, held in the open area at the rear of the plant, was very positive. He said, “It led to several sales immediately.”

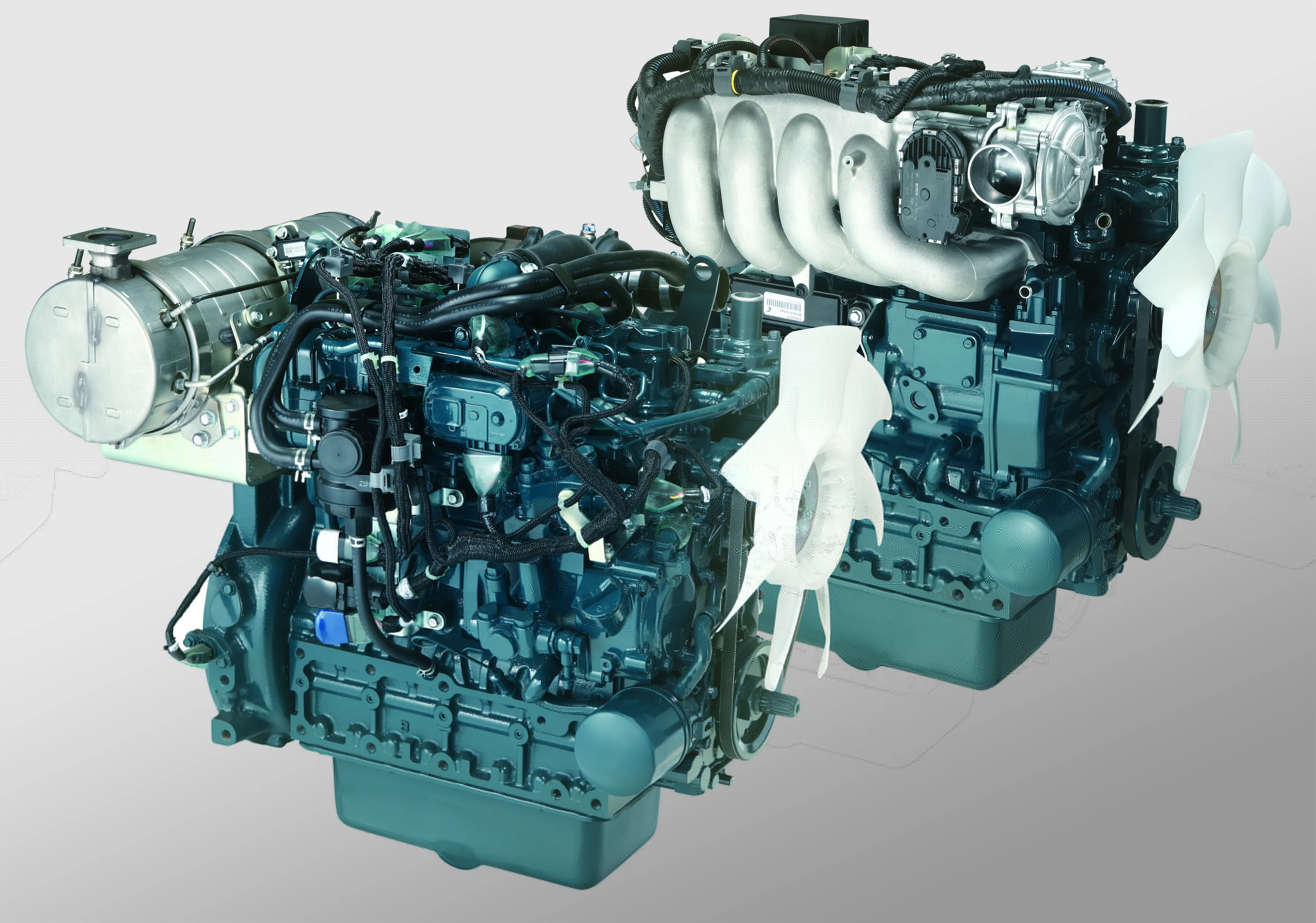

In addition, Power Curbers is keen to ensure that its customers have the widest possible array of machine options available. A new generation, low emission engine is now being offered for the 5700-C slipformer, aimed at those contractors operating equipment in low emission zones or those that want to plan ahead for upcoming emissions regulations. The Tier 4 Final compliant196 Cummins diesel slots into the existing machine chassis with no necessary modifications.

He added that the use of stringless systems is by no means limited to the larger contractors for use on large highway jobs either. He said, “It’s for sub-contractors now as well.”

The firm recently held a demonstration event for its machines that highlighted that working benefits of using stringless systems. The invitees included a diverse array of contractors ranging from small specialist firms right up to larger companies. Bullock said that the customer response to the demonstration, held in the open area at the rear of the plant, was very positive. He said, “It led to several sales immediately.”

In addition, Power Curbers is keen to ensure that its customers have the widest possible array of machine options available. A new generation, low emission engine is now being offered for the 5700-C slipformer, aimed at those contractors operating equipment in low emission zones or those that want to plan ahead for upcoming emissions regulations. The Tier 4 Final compliant