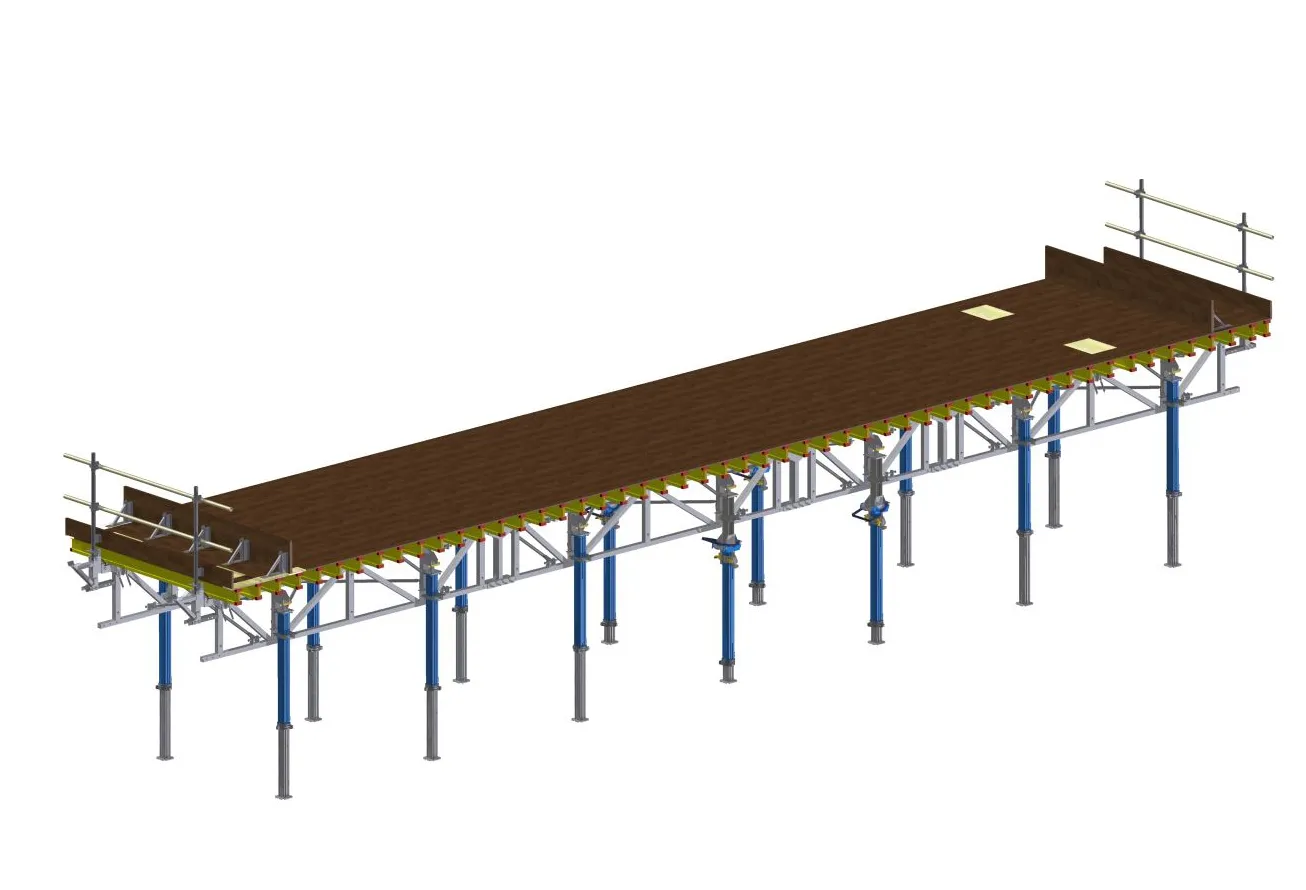

Pilosio’s new flying table ST80 is ideal for high construction work where pouring cycles repeat from one level to another. Flying forms are constituted by large sections of formwork, featuring supporting trusses, joists and aluminum posts. This system is used to cast slab areas with tables that can be designed in order to reach up to lengths of 30m and widths of 6m. The system enhances also side flaps in order to handle spaces between columns and slab edges.

January 6, 2017

Read time: 2 mins

The company’s new climbing bracket 240 allows a wide range of flexibility according to building geometries. A suspension shoe allows easy connection of the bracket to a concrete wall and the bracket it tiltable. It is designed to erect formwork with heights up to 5.5m. The carriage can slide back of 75cm to ensure enough space to install concrete rebars and clean formwork surface.

Typical applications of this bracket are construction sites that require working platforms to support double-sided panel formwork. The formwork is firmly connected to the supporting bracket and the whole assembly can be lifted together as a unit with cranes. The system consists of the climbing bracket itself, the wall strut, the lower bridge and guard rails. This supporting bracket is fully compatible with all vertical formwork systems supplied by Pilosio, both steel framed formwork panels and MAXIMIX system.

Accompanying all this is Pilosio’s latest aluminum prop, the Slabprop 2.0. Improvements, when compared to the old version, include a greater range of extraction, from 145cm-625cm. It has greater capacity with values up to 76kN - certified according to EN 16031. Also, connection to truss frames is permitted all along the prop, in order to assemble load-bearing towers with high capacity. The new SLABPROP 2.0 is totally compatible with Slabform and Liteform panel systems.