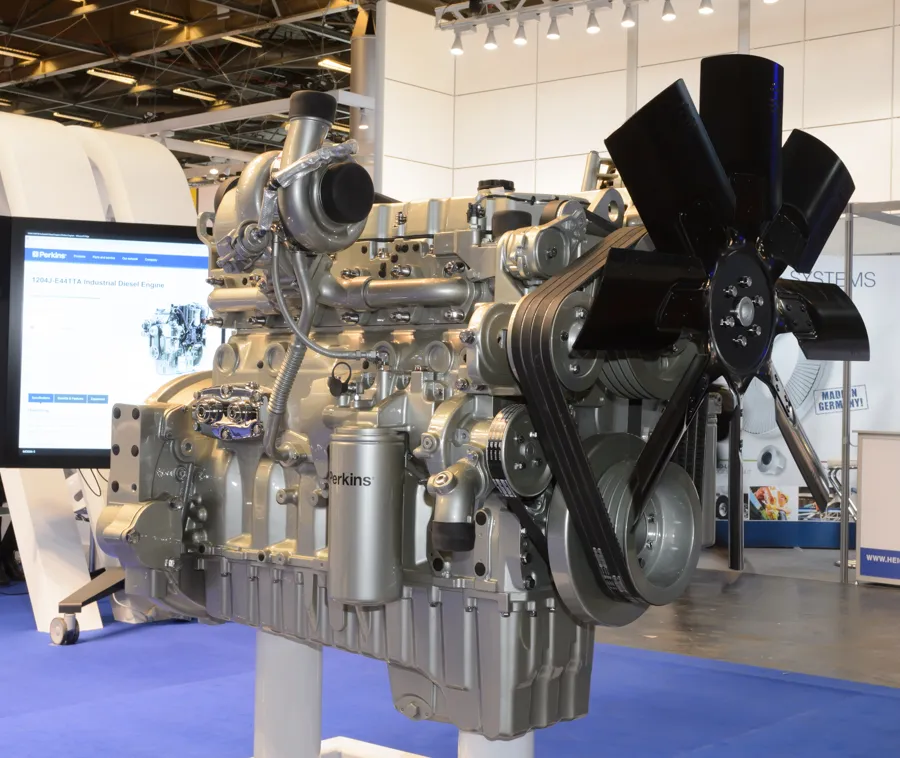

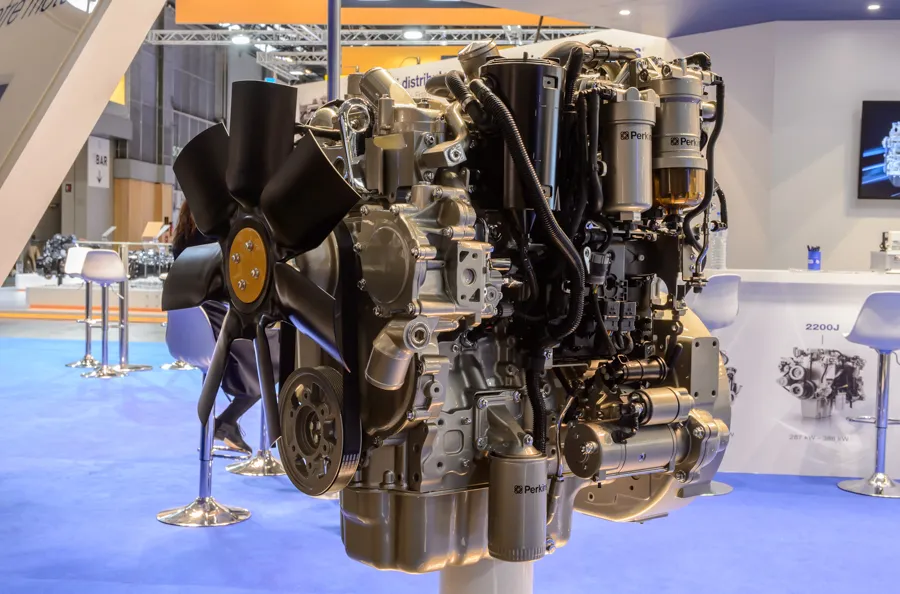

As the Perkins engine range continues to evolve, considerable upgrades have been made to offer more value to end users. One example is the Perkins 1204J-E44TTA, which now delivers up to 150kW, representing a 15% increase in power over its stage IV predecessor.

Perkins said that fuel consumption has been reduced by 5%, torque is up by 5-10% and the resulting improved characteristics of this 4.4 litre engine could enable OEMs to downsize without compromising on performance.

April 25, 2018

Read time: 1 min

As the 299 Perkins engine range continues to evolve, considerable upgrades have been made to offer more value to end users. One example is the Perkins 1204J-E44TTA, which now delivers up to 150kW, representing a 15% increase in power over its stage IV predecessor.

Perkins said that fuel consumption has been reduced by 5%, torque is up by 5-10% and the resulting improved characteristics of this 4.4 litre engine could enable OEMs to downsize without compromising on performance.

In addition, there is no change in exhaust after-treatment size in the move from stage IV to V, and a reduced cooling package size should enable integration with minimal re-engineering.