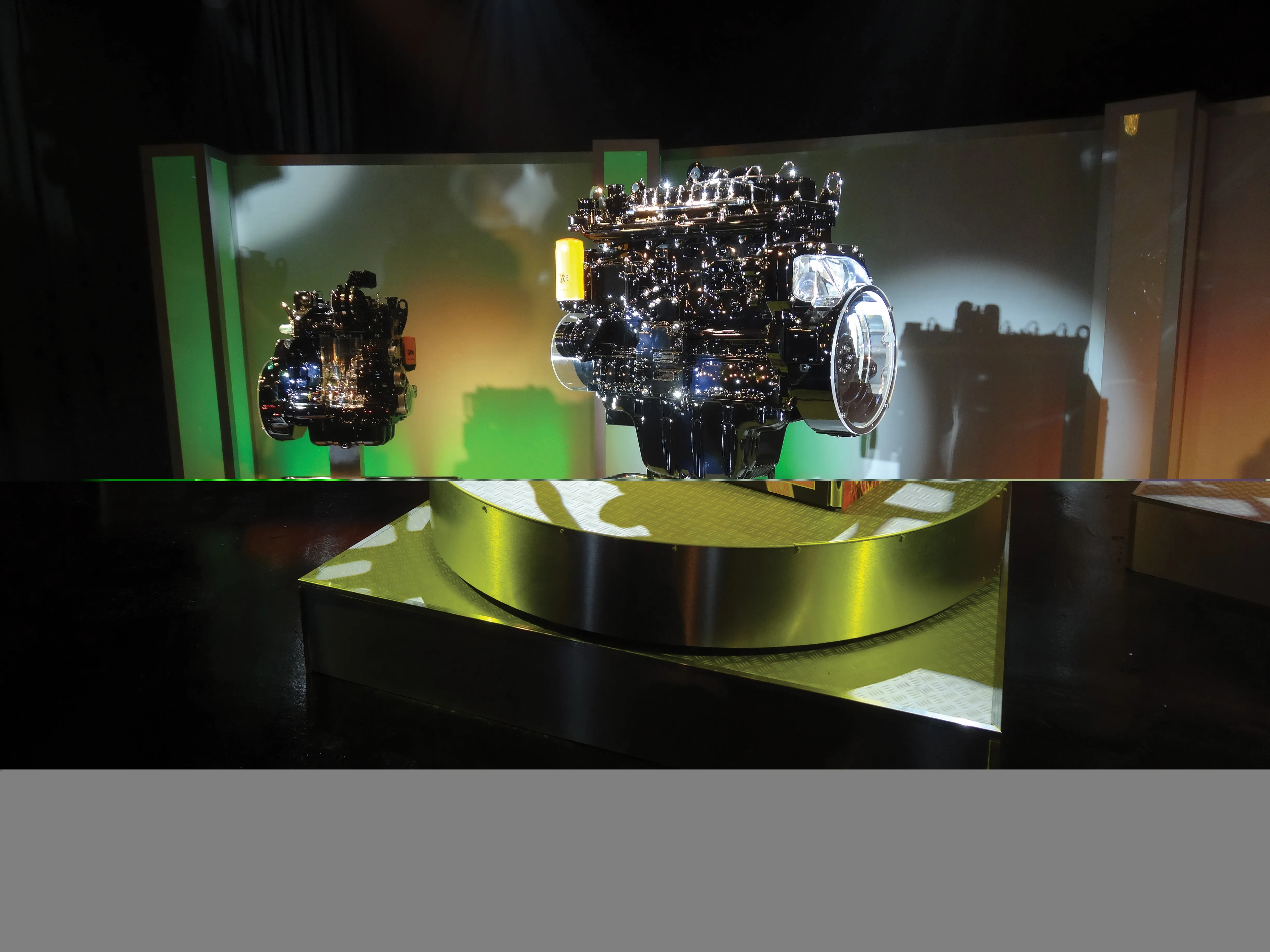

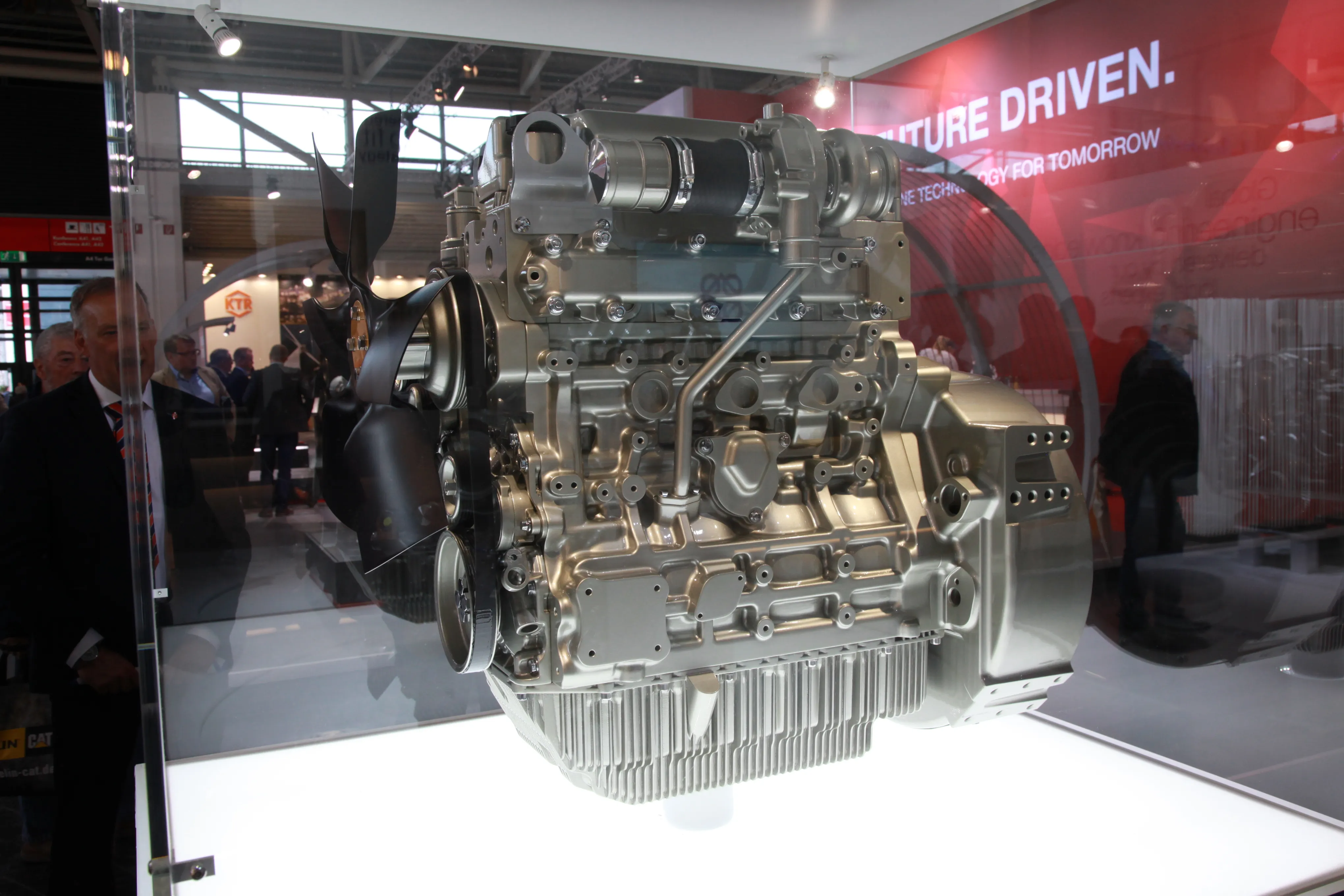

Perkins has developed a new compact engine platform for its Syncro range. Available in 2.8 and 3.6litre capacities with power outputs of 55kW and 100kW respectively, the all-new engine platform offers more choice for OEMs looking to downsize and increase power density within existing applications.

“We’ve carried out a lot of collaborative engineering with OEMs to determine their exact requirements for compact power units,” said Oliver Lythgoe, who is responsible for product concept marketing at Perkins. “W

April 15, 2016

Read time: 2 mins

“We’ve carried out a lot of collaborative engineering with OEMs to determine their exact requirements for compact power units,” said Oliver Lythgoe, who is responsible for product concept marketing at Perkins. “We will be continuing with EGR and DPF technologies, but a flexible approach to emissions packaging will ensure we can offer greater efficiency without increasing space requirements.”

In addition, he added that a new process of EGR management involves piping the spent gases through the cylinder head before reaching the intake valve. It is a development that prevents over-cooling of gases and the unwanted production of condensate, yet it offers enough temperature drop to reduce the impact on existing cooling systems.

“The Syncro product represents the very best of Perkins innovation,” he said. “With a revised combustion process, we are producing a much cleaner burn, which reduces the amount of work that the after-treatment system is required to do.”