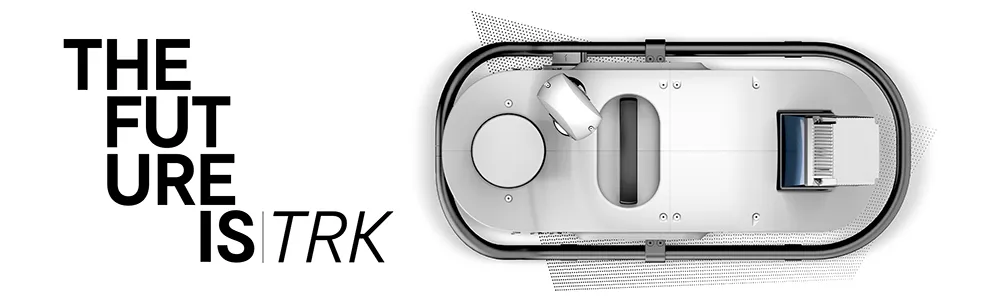

Equipped with CAN-bus sensor technology, the T1 LOADER LFT compensates for both transverse and longitudinal terrain inclinations, ensuring accurate weight readings even on uneven surfaces. It also monitors hydraulic system temperature to maintain optimal performance and longevity. Additionally, the system automatically manages bucket position control, ensuring a stable centre of gravity for the loaded material, thereby enhancing safety and efficiency.

Advanced AI algorithms further improve the system’s capabilities, accelerating weight readings and enhancing visualisation for real-time decision-making. By delivering certified and validated data, the T1 LOADER LFT enables operators to optimise workflows, reduce material waste, and enhance overall profitability.

To ensure data security and integrity, the system features robust protection against tampering and unauthorised access. The user-friendly interface, with intuitive graphic icons and clear visual cues, simplifies operations, minimising errors and streamlining productivity.

Visitors to OUTSET’s booth (Hall A6, Stand 400) at bauma 2025 will have the opportunity to experience this groundbreaking technology firsthand. Designed for seamless integration into third-party sales and distribution networks, the T1 LOADER LFT is set to revolutionise the industry, reaffirming OUTSET’s commitment to innovation and excellence in on board weighing solutions.

Stand: A6 400