The hybrid and renewable energy system comes in three models - 12kWh, 23kWh and 35kWh, with further options due soon.

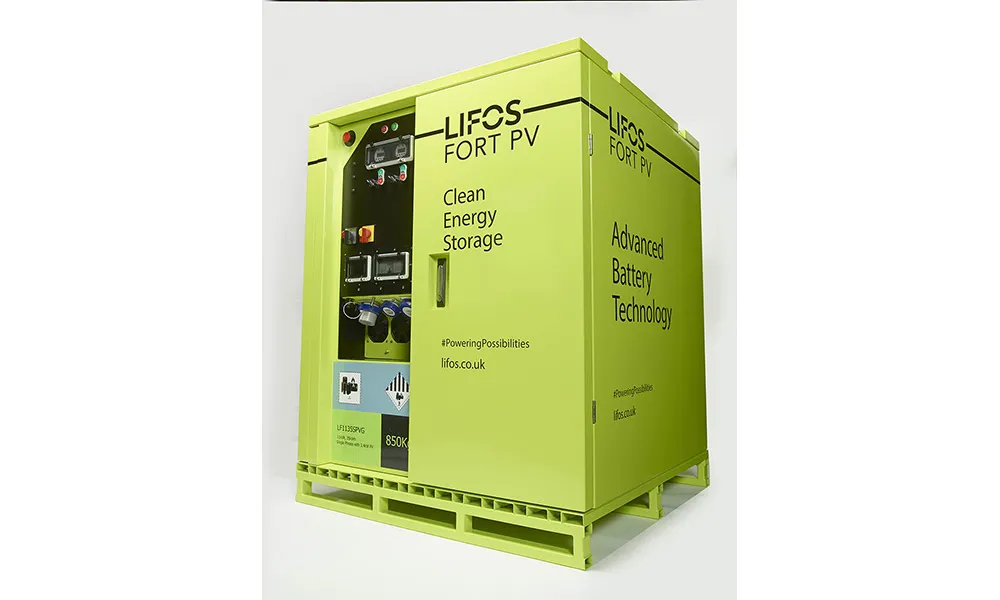

The Fort has 18 solar panels delivering 3.4kW of green power that can be quickly deployed either by using the fitted solar panel kick stand or the optional container roof mounting kit. The kit makes it suit site use and it can be fixed onto the roof of a welfare unit, while the design allows for easy transportation. LIFOS Fort batteries use A grade lithium-ion phosphate battery cells, offering longevity, reliability and traceability.

The Fort comes with a five-year warranty but all Fort customers have the option to join the LIFOS Seven-Year-Switch programme. This allows customers at the end of year seven to upgrade critical components so the battery is operating like new, extending the life expectancy of the asset to 15 years and beyond.

In addition, LIFOS has designed the LiQ Battery Management software to remotely control, monitor and report data from the Fort. It will provide information on diesel usage, CO2 savings and solar power generation for easier ESG reporting.