New technologies are being introduced by Oerlikon Drive Systems at the bauma China event in Shanghai that are aimed at Asian and global markets. The firm has new systems for both its Oerlikon Graziano and Oerlikon Fairfield brands, with a key launch being the latest hybrid electric drivetrain technology. Also new is the advanced Shifting solutions package, which is said to provide integrated solutions for all construction machinery applications.

November 25, 2014

Read time: 2 mins

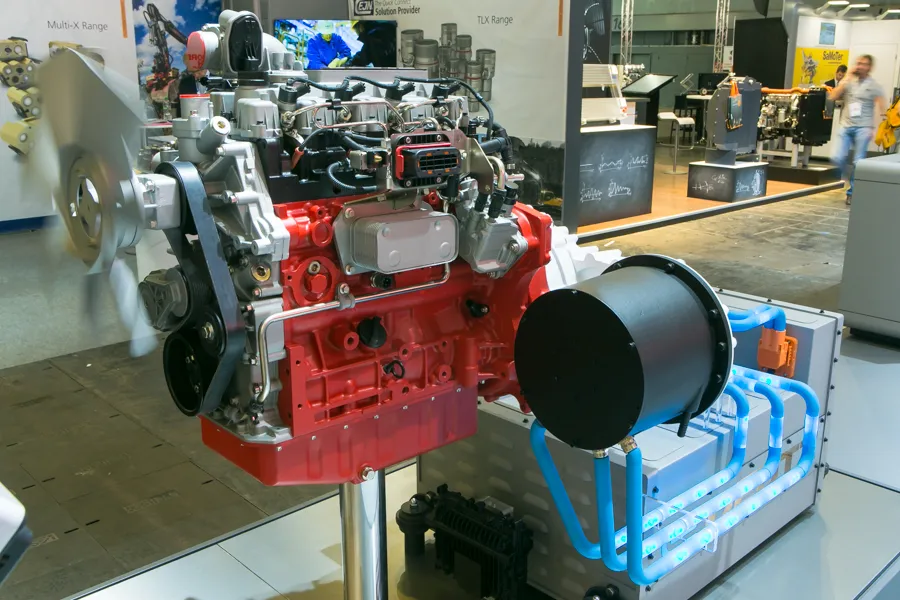

New technologies are being introduced by 7214 Oerlikon Drive Systems at the bauma China event in Shanghai that are aimed at Asian and global markets. The firm has new systems for both its Oerlikon Graziano and Oerlikon Fairfield brands, with a key launch being the latest hybrid electric drivetrain technology. Also new is the advanced Shifting solutions package, which is said to provide integrated solutions for all construction machinery applications.

The innovative hybrid electric drivetrain technology offers a complete driveline system from engine to wheel and designed specifically for arduous off-highway applications. The patent-pending system is modular in design, which allow sit to suit duties in a wide range of machines for construction and extraction duties. Meanwhile the Shifting Solution package encompasses complete transmission systems that are fully-integrated for maximum efficiency and which can be installed in a wide array of machine types. Other products on display include axle systems for motor graders and wheel loaders, as well as planetary drives.

The innovative hybrid electric drivetrain technology offers a complete driveline system from engine to wheel and designed specifically for arduous off-highway applications. The patent-pending system is modular in design, which allow sit to suit duties in a wide range of machines for construction and extraction duties. Meanwhile the Shifting Solution package encompasses complete transmission systems that are fully-integrated for maximum efficiency and which can be installed in a wide array of machine types. Other products on display include axle systems for motor graders and wheel loaders, as well as planetary drives.