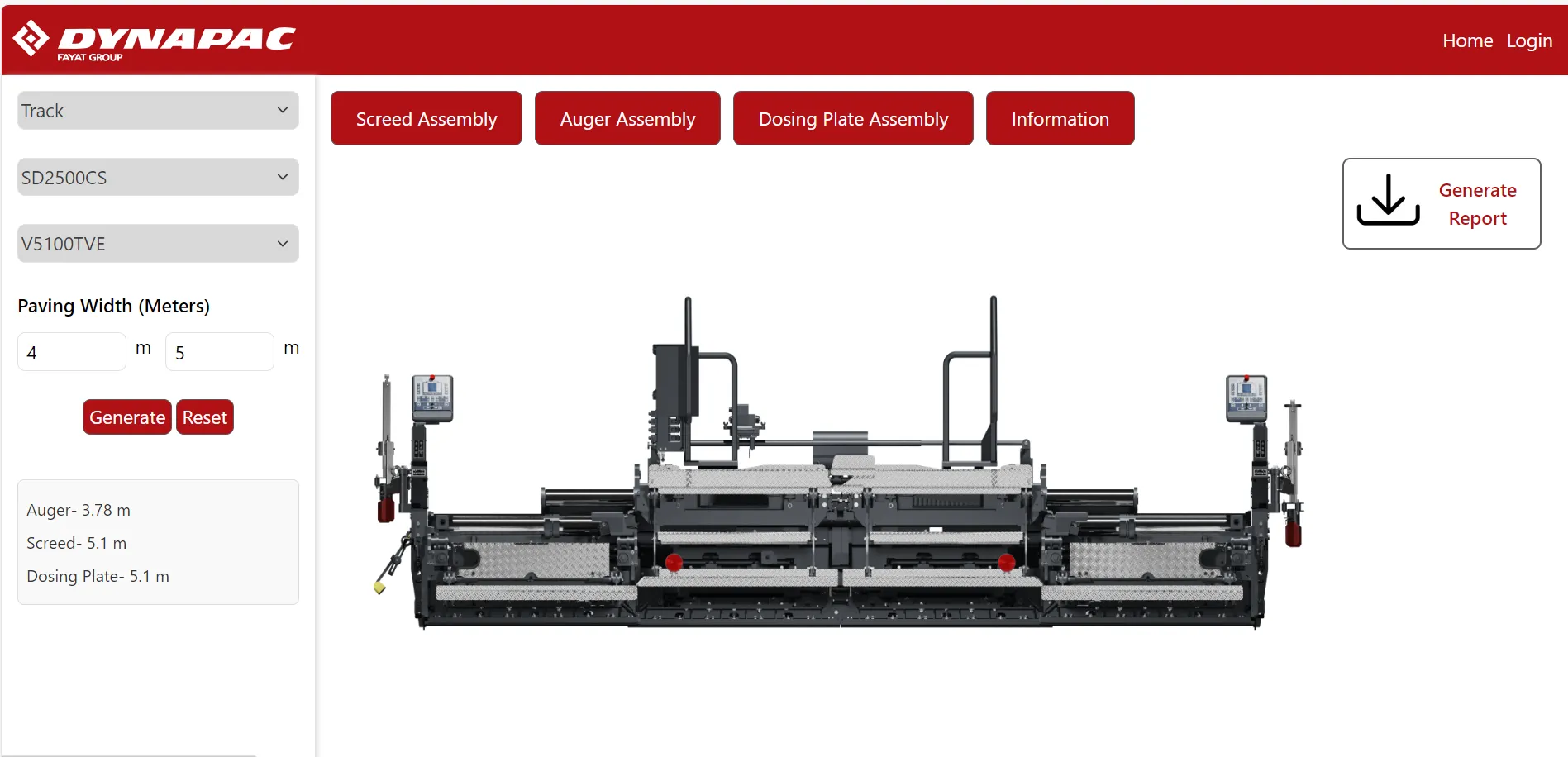

With just a few key inputs — such as tractor type, screed model, and desired minimum and maximum paving widths — the Dynapac Screed Configurator instantly generates a tailored configuration. The intuitive user interface guides operators step-by-step through the setup process, aligning settings exactly with the actual paving width. This level of precision results in significant improvements in operational efficiency, reduces downtime, and minimizes wear on critical components.

Precise Documentation for Quality Assurance

The Screed Configurator not only optimizes setup but also allows users to export all configuration details in a comprehensive digital report. This report can be saved or printed, providing complete documentation for audits, quality assurance processes, and future reference. Each report includes essential data on configured paving widths and parameters for each component, ensuring transparency and traceability during paving operations.

“Precise Adjustment to Actual Paving Width”

“Our new Screed Configurator is designed to make the setup process faster, easier, and more precise for paving professionals,” says Sönke Demuth, Head of Global Product Management Paving at Dynapac. “By matching the configuration exactly to the actual paving width, we help our customers accelerate their workflows while simultaneously extending the lifespan of their machines. This delivers real added value to their daily operations.”

The Screed Configurator is now available. For more information please contact our Product Marketing Team: [email protected]

Dynapac is a leading supplier of high-tech soil and asphalt rollers, light equipment, and pavers committed to strengthening customer performance by being a partner on the road ahead. Dynapac is represented worldwide via its regional sales- and service offices and cooperates with an extensive and professional distribution network. Headquartered in Wardenburg, Germany, Dynapac has production facilities in Europe, South America and Asia. Dynapac is part of the FAYAT Group.

Content produced in association with Dynapac