Belgium-based steel producer NLMK Clabecq has developed a new thickness for its Quard steel product range. This development follows on from the firm’s heavy investment in its steel rolling facility. The surface quality of this plate steel is said to be very high also and the firm claims that the finish of steel from rivals has a rougher finish.

Marketing manager Bernard Robins said, “It enables us to produce thin plates with thicknesses from 3.2mm.” and he added, “We are the only ones in the world able t

February 10, 2016

Read time: 2 mins

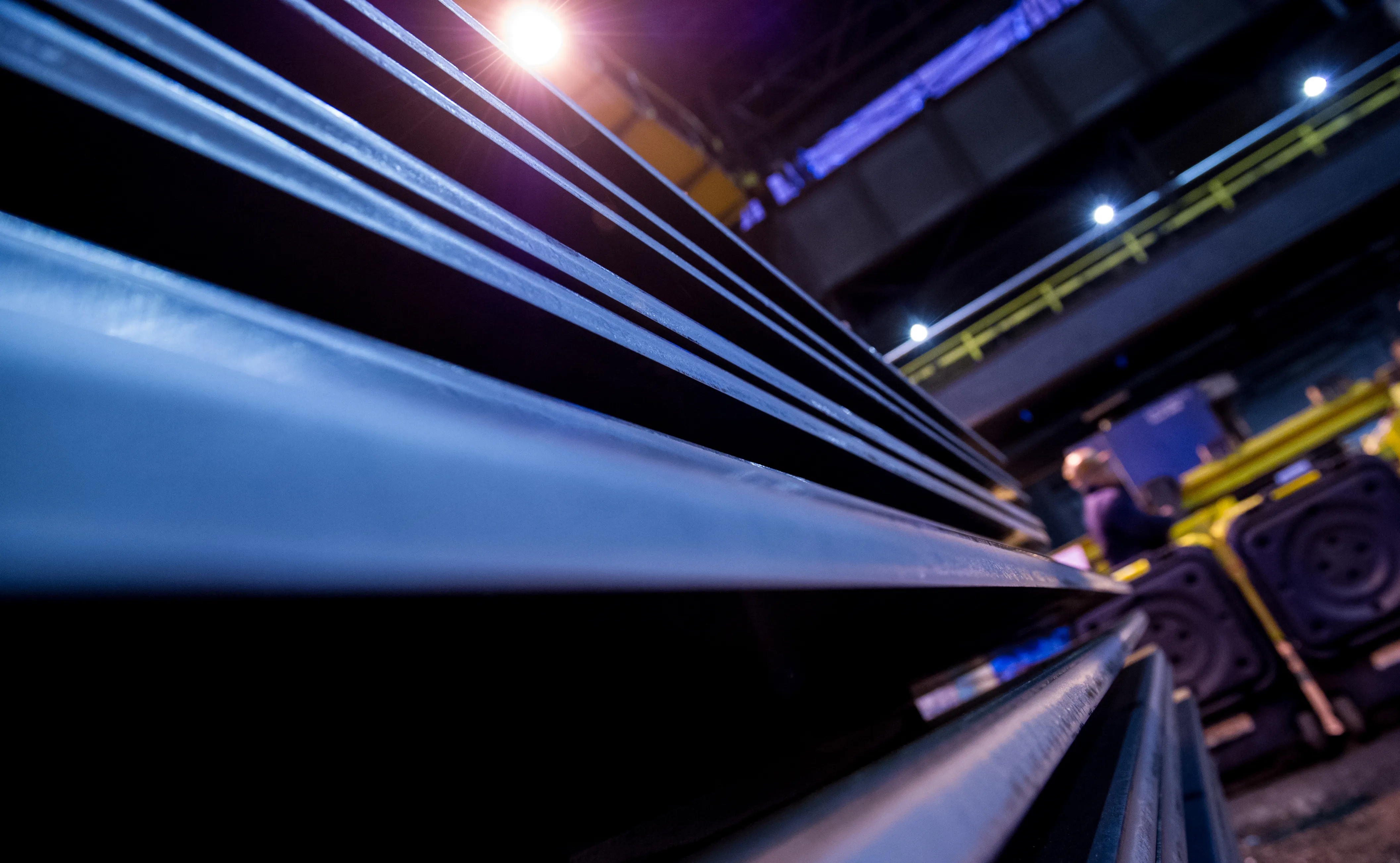

Belgium-based steel producer 2323 NLMK Clabecq has developed a new thickness for its Quard steel product range. This development follows on from the firm’s heavy investment in its steel rolling facility. The surface quality of this plate steel is said to be very high also and the firm claims that the finish of steel from rivals has a rougher finish.

Marketing manager Bernard Robins said, “It enables us to produce thin plates with thicknesses from 3.2mm.” and he added, “We are the only ones in the world able to produce that thickness with our width.”

Robins also said that the steel has a very homogenous grain pattern right across the plate and added, “When you cut it, the reaction is more predictable. It takes less time to cut a piece than steel from our competitors.”

The steel is said to be easier to work and is produced in a high speed production process that allows the firm to meet customer demand quickly. Because NLMK Clabecq produces the plate in wider sections than its competitors, Robins said that this offers additional benefits. For dump body construction for example, it allows the manufacture of flat floor bodies for some applications, without the need to weld two plates along the centre and reduces manufacturing time and cost.

The company is also carrying out testing of new grades of its wear-resistant Quard and Quend structural steel grades at present, with testing being carried out in partnership with some key customers.

All videos

Marketing manager Bernard Robins said, “It enables us to produce thin plates with thicknesses from 3.2mm.” and he added, “We are the only ones in the world able to produce that thickness with our width.”

Robins also said that the steel has a very homogenous grain pattern right across the plate and added, “When you cut it, the reaction is more predictable. It takes less time to cut a piece than steel from our competitors.”

The steel is said to be easier to work and is produced in a high speed production process that allows the firm to meet customer demand quickly. Because NLMK Clabecq produces the plate in wider sections than its competitors, Robins said that this offers additional benefits. For dump body construction for example, it allows the manufacture of flat floor bodies for some applications, without the need to weld two plates along the centre and reduces manufacturing time and cost.

The company is also carrying out testing of new grades of its wear-resistant Quard and Quend structural steel grades at present, with testing being carried out in partnership with some key customers.

All videos