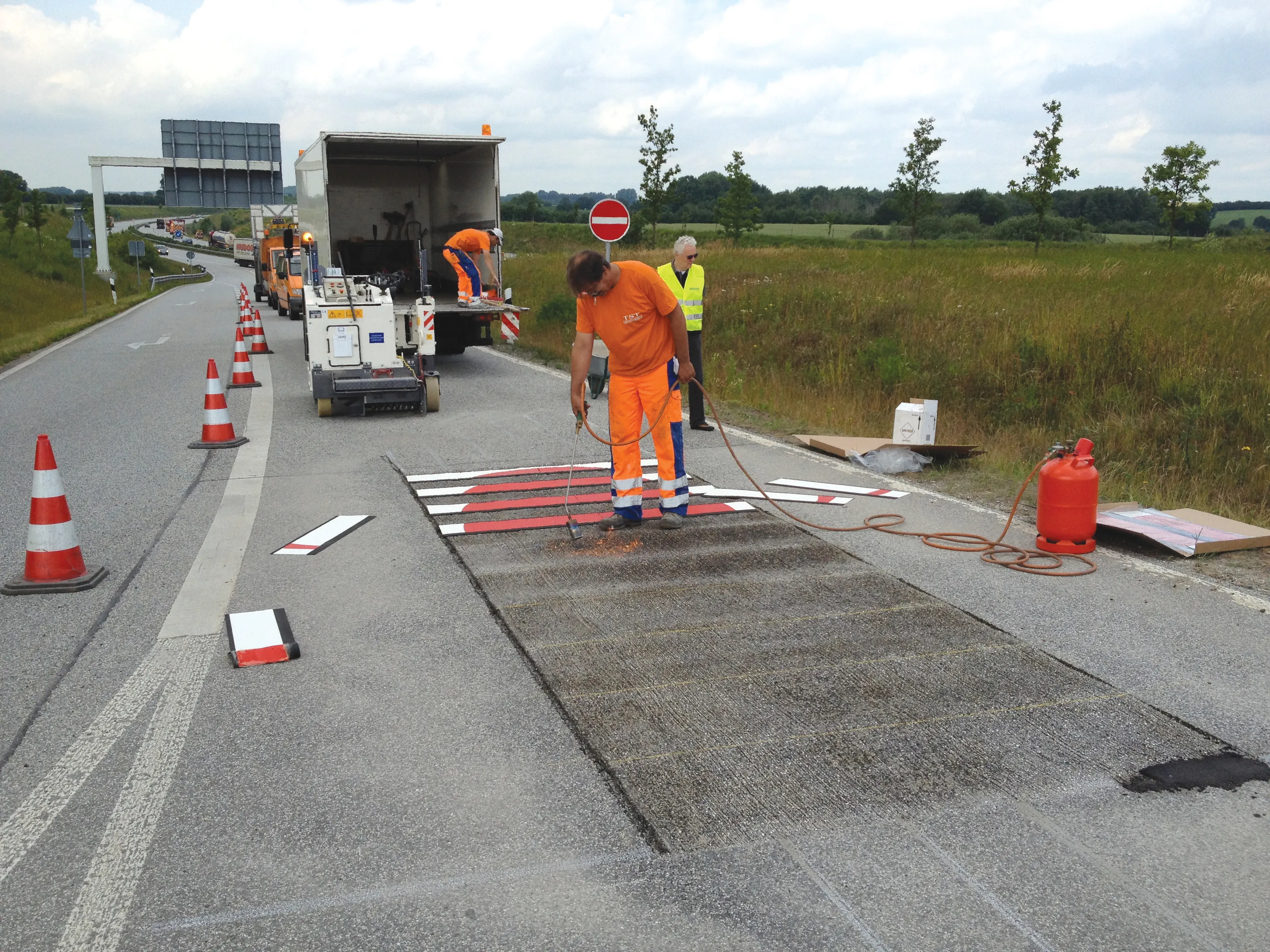

Kögel unveiled its new, fully insulated asphalt tipper trailer. “We now transport more safely and efficiently than ever before,” said Volker Seitz, head of business development and marketing/communications. The three-axle tipper trailer has a 24 m3 loading volume, a 5 mm thick tipper body bottom, a 4 mm thick wall made of tempered Hardox 450 steel and side walls made from high-strength, 4 mm S700 steel sheets.

“It offers load-bearing capacity and durability,” Seitz said. “Resale values should hold

April 13, 2016

Read time: 2 mins

“We now transport more safely and efficiently than ever before,” said Volker Seitz, head of business development and marketing/communications.

The three-axle tipper trailer has a 24 m3 loading volume, a 5 mm thick tipper body bottom, a 4 mm thick wall made of tempered Hardox 450 steel and side walls made from high-strength, 4 mm S700 steel sheets.

“It offers load-bearing capacity and durability,” Seitz said. “Resale values should hold high.”

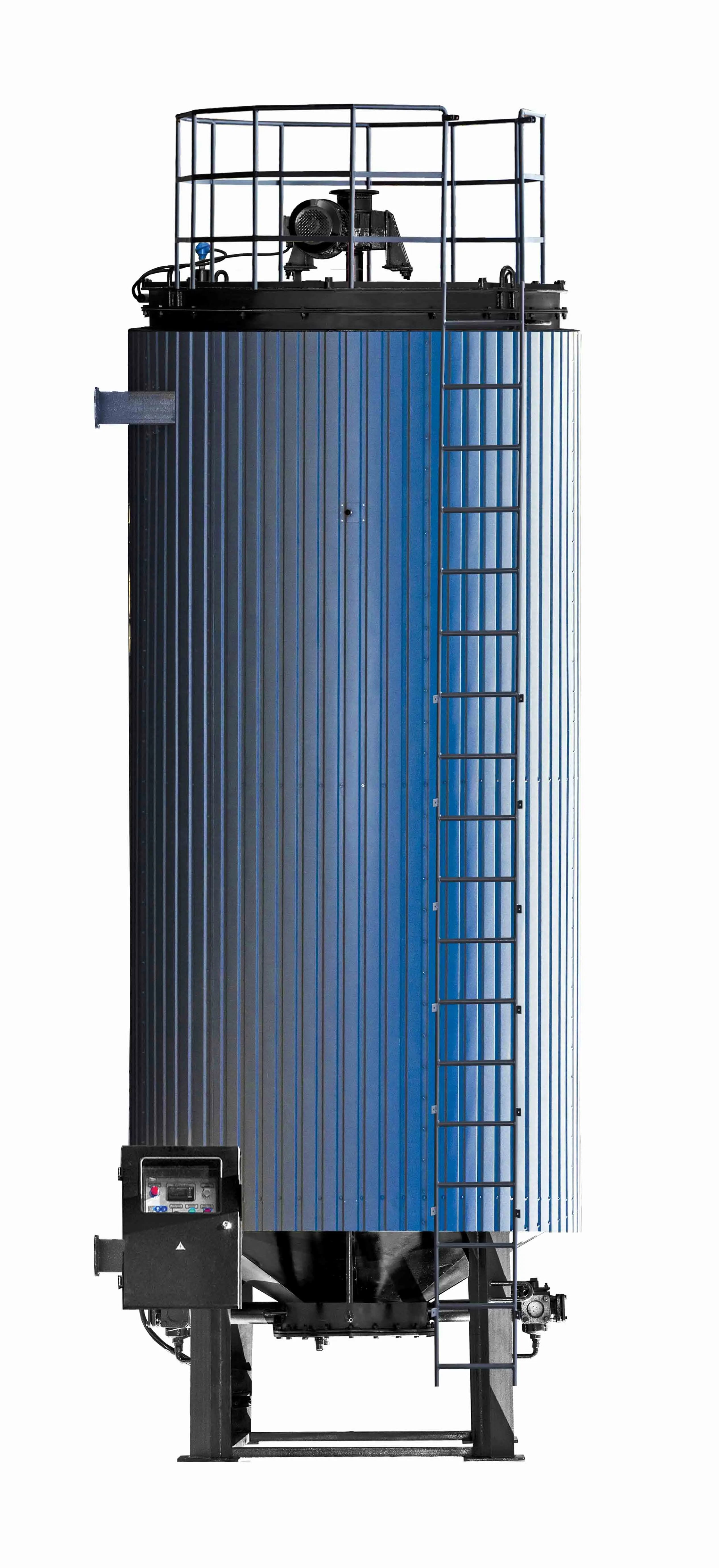

The combination is optimally suited for daily, practical use with asphalt mixtures and gravel. The body of the tipper trailer is fully insulated and equipped with an integrated four-point measuring system and temperature display unit with an optional available printer.

The insulation is based on a thermosetting, high-performance material specially suited to high temperatures up to 200O C.

The tipper trailers maintain the 170 mm extension of the body hang that Kögel introduced in 2014. This removes the need for an optionally attachable chute and the weight that goes with it.