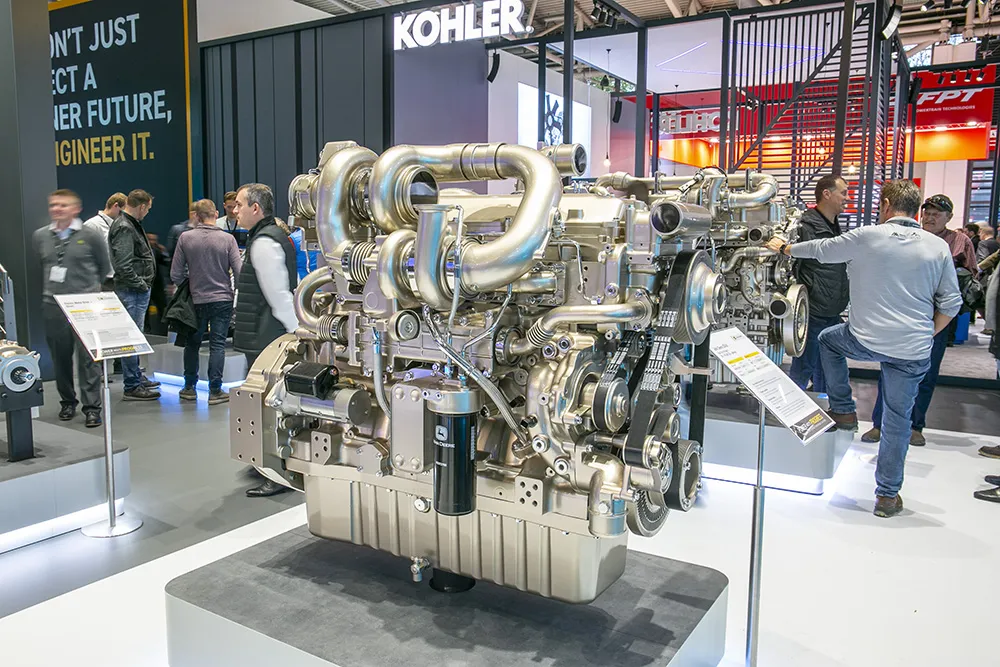

Engine specialist from the firm, Nicholas Pfeiffer commented, “The 14 and 18 are the next generation of engines from us. They’ve been developed with a focus on serviceability and have the latest diagnostics.” He explained that that the diagnostics ensure that the engines offer predictive maintenance capabilities, catching potential faults before they develop and making significant reductions in maintenance costs while also preventing unplanned downtime.

He said, “We have our telematics gateway and if you opt in, the dealer is able to call you even before you know there’s an issue.”

Meanwhile, the wiring harnesses are all external to the engines making them easier to maintain and also less vulnerable to damage. Customers are also able to select different fuel and oil filter locations to best suit the installation. Pfeiffer added that the simplification of the aftertreatment package for the JD18 engine offers significant benefits also, with fewer sensors required and a further reduction in maintenance costs. These engines are biofuel capable and Pfeiffer added, “We are working on HVO.”