The firm claims that the attachments are all improved to boost strength and durability, as well as to improve opening and closing times.

By using hydraulic cylinders with higher working pressures, the firm says it has been able to increase the power of the attachments by 22%, and in some cases up to 35%. In addition, the valves mounted on the cylinders are optimised so that cycle times are faster. Because these valves are located externally on the outside of the cylinder, they are accessible for service and maintenance.

The HCC series now benefits from a new type of changeable penetration teeth already applied in the HCS series. These teeth have a better penetrating ability in concrete, which has optimised the crushing force of the units. The combination of these modifications resulted in a 35% greater efficiency of the scissors.

In addition to the conventional jaws fitted as standard in the HCC series, the firm also offers its high-penetration jaw (HPJ) design. These shorter jaws have been designed to be able to transfer more force. The Hydraram HPJ jaws have up to 30% higher penetration force than the standard HCC jaws. In addition, the new HCC series can be equipped with an automatic lubrication system.

The HFP-M pulveriser has an integrated magnet that is powered by the 24V system on the excavator. No additional alternator is required and the unit is easy to install. The magnet function can be switched on by the operator to collect reinforcement steel during crushing. The magnets have a quick release system so that the metal is ejected as soon as the power is switched off.

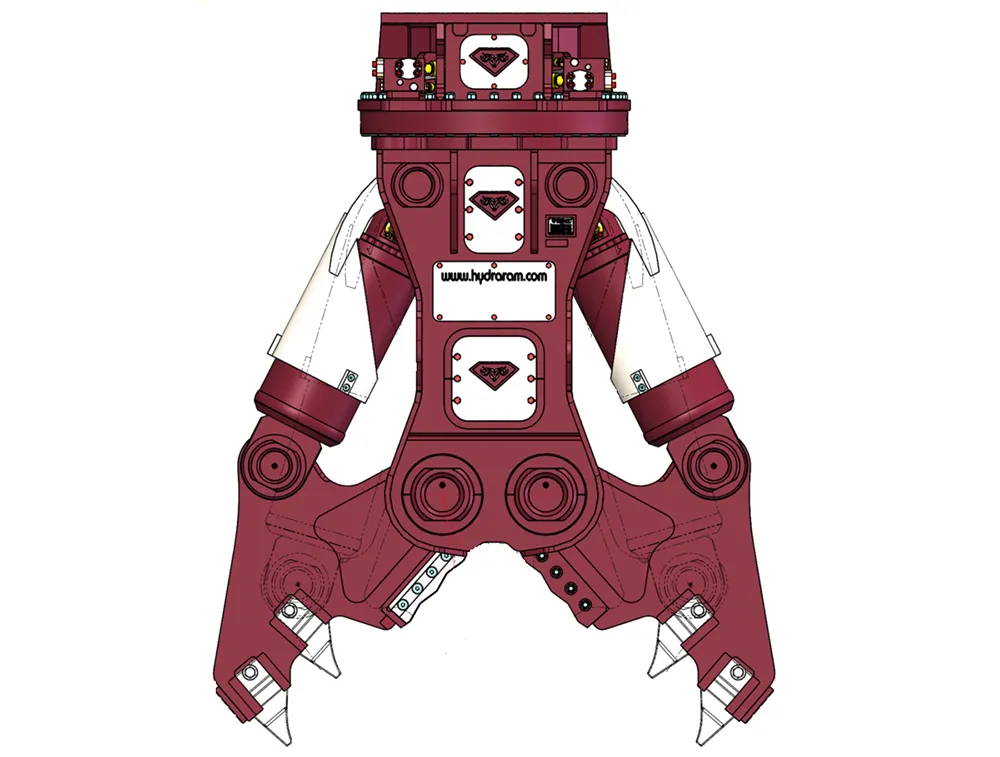

Meanwhile, the HDG grab range has been extended to 25 models that weigh from 75kg to over 14tonnes. These can be matched to excavators from 1-250tonnes. The new HDG series is said to offer more powerful inner cylinders with end damping, with twin reinforced rotation motors for greater torque.