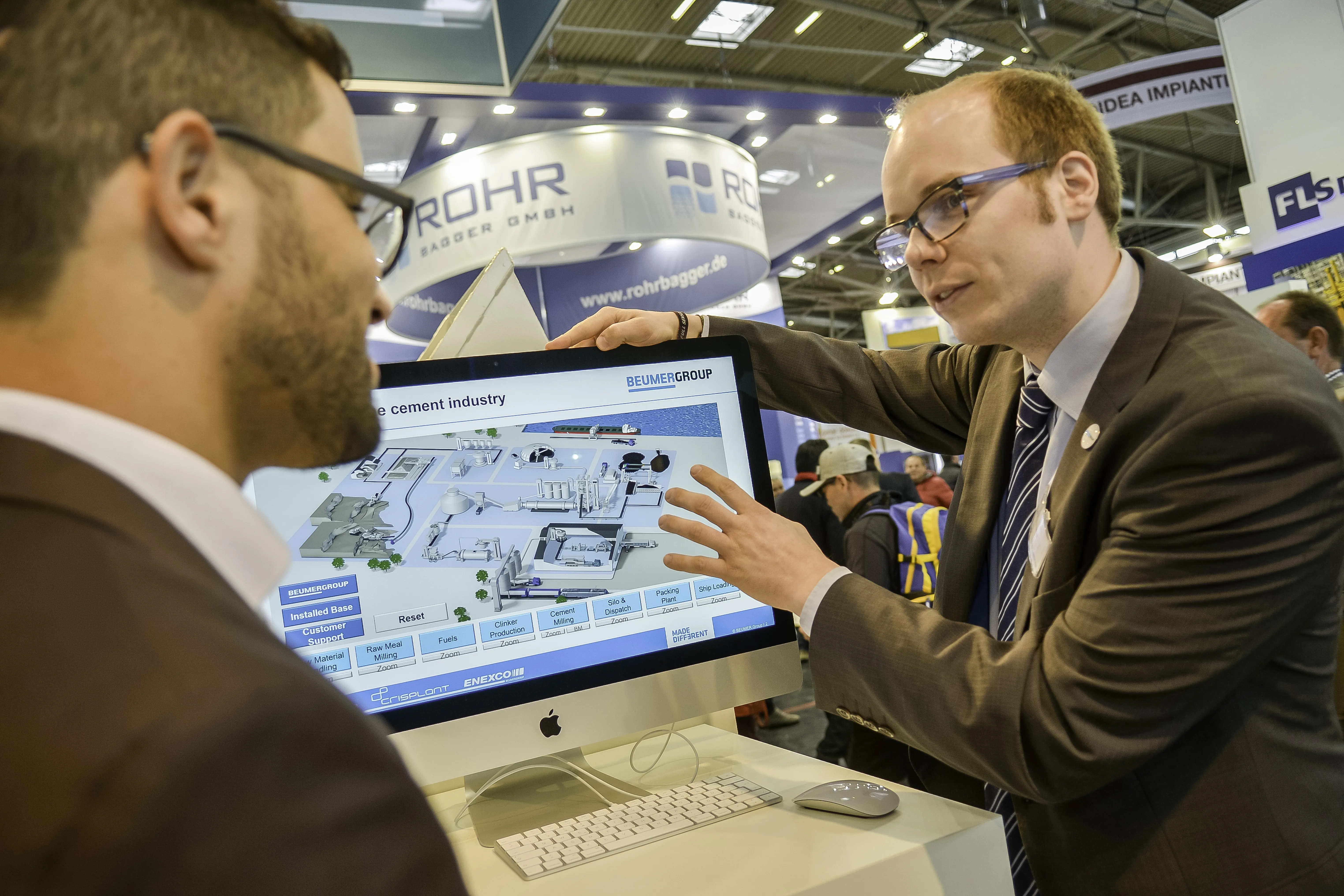

BEUMER Group has unveiled its latest effort to create cost savings at cement plants.

Autopac 3000 is an economic and efficient system for simultaneous loading and palletising of bagged material including cement, lime and gypsum used in construction.

The process eliminates the need for hand bagging, which is time consuming and imprecise.

A conveyor delivers the bags and also acts as a second quality control check. The bags are weighed as they move, and those that don’t register properly are returned

April 15, 2016

Read time: 2 mins

Autopac 3000 is an economic and efficient system for simultaneous loading and palletising of bagged material including cement, lime and gypsum used in construction.

The process eliminates the need for hand bagging, which is time consuming and imprecise.

A conveyor delivers the bags and also acts as a second quality control check. The bags are weighed as they move, and those that don’t register properly are returned for reprocessing.

The remainder of the bags continue to the truck and are automatically loaded. Autopac has a loading capacity of 3,000 bags per hour.

“The cement industry is very old but we always try to make the process better,” said Jawad Baidari, an engineer and sales manager at BEUMER. “The bags don’t have to be loaded by hand, and loading is much more easy and accurate.”

The process is simple for drivers, too. They park their open trucks in a designated location, then access an intuitive display. A few touches later the bags are being loaded – quickly and with efficient use of space.