“The Ammann APR 52/75 and APR 58/75 outperform rivals in speed, both forward and reverse – an advantage that is supported by data,” said Ralf Brutschin. “The previous Ammann models were the fastest on the market, and these plates can make the same claim. They are also great climbers.”

During field testing, operators said the new Ammann APR 52/75 and APR 58/75 outpaced competitors’ plates in terms of handling, manoeuvrability, compaction performance and speed, which is 29 m/min (1.1 mph).

“The plates also reflect reduced hand-arm vibration when in reverse,” Ralf Brutschin said. “This is even more impressive given HAV levels for the previous models, the APR 49/20 and APR 59/20, were already the lowest in the industry.”

The re-engineered plates present a new look that was welcomed by customers during testing. The biggest design change is the use of protective tubes to guard the plates instead of hoods.

“The elimination of the hoods creates consistency with other former redesigned Ammann plates,” Brutschin said. “It also makes the machines lighter.”

Engine choices

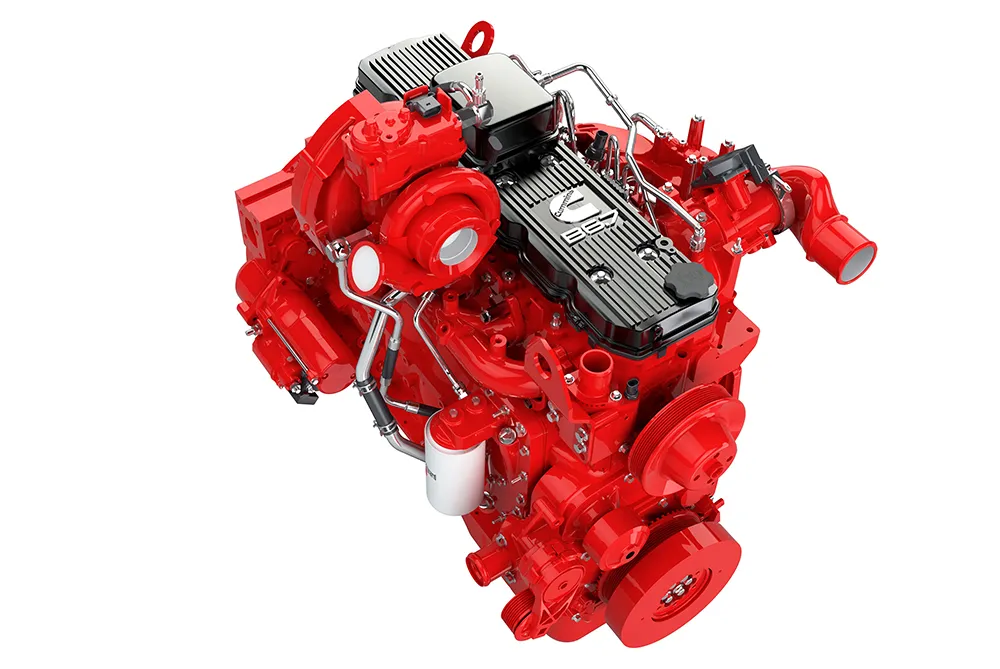

The lack of a hood improves air circulation, which makes it possible to utilise petrol engines that could otherwise overheat. A diesel engine with DPF is available for those customers who face specific environmental standards or work in confined spaces.

The new APR 52/75 and APR 58/75 offer four engine configurations:

- Hatz 1B40 diesel e-start (current EMEA)

- Hatz 1B50E diesel e-start EPA (current US)

- Hatz 1B50E diesel e-start EPA with DPF

- Honda GX390 petrol hand-start

Other new key selling points include:

- Larger lashing hooks with 10-tonne capacity.

- A smaller battery that performs comparably to its larger predecessor. The battery has jump-start capability for charging during longer standing times.

- An improved drawbar that leads to better manoeuvrability and lower HAV when in reverse.

- An improved V-belt system that achieved longer service life in endurance tests.

- Because the hood was eliminated, operators have easy access to the engine and other components, simplifying oil checks and changes.

Building off previous success

Both plate variants have working widths of 450 mm (17.7 in) that can be expanded with extensions of 75 mm (3 in) or 150 mm (5.9 in). Varied weights and therefore compaction outputs separate the machines.

The twin-shaft exciter unit continues to be a key advantage for the plates. Shaft positioning enables the operator to effortlessly change directions. The smooth, variable hydrostatic unit allows the machines to move easily in forward and reverse. On-the-spot vibration can be utilised in particularly challenging areas.

Ready for rent

The intuitive nature of the APR 52/75 and APR 58/75 ensure even inexperienced operators can perform productively, making the plates great additions to rental fleets. Rental businesses will also appreciate that maintenance costs are low, and intervals between fluid and filter changes are long.

To find out more about the products click here:

APR 52/75 - Powerful Reversible Plate Compactor

APR 58/75 - Powerful Reversible Plate Compactor