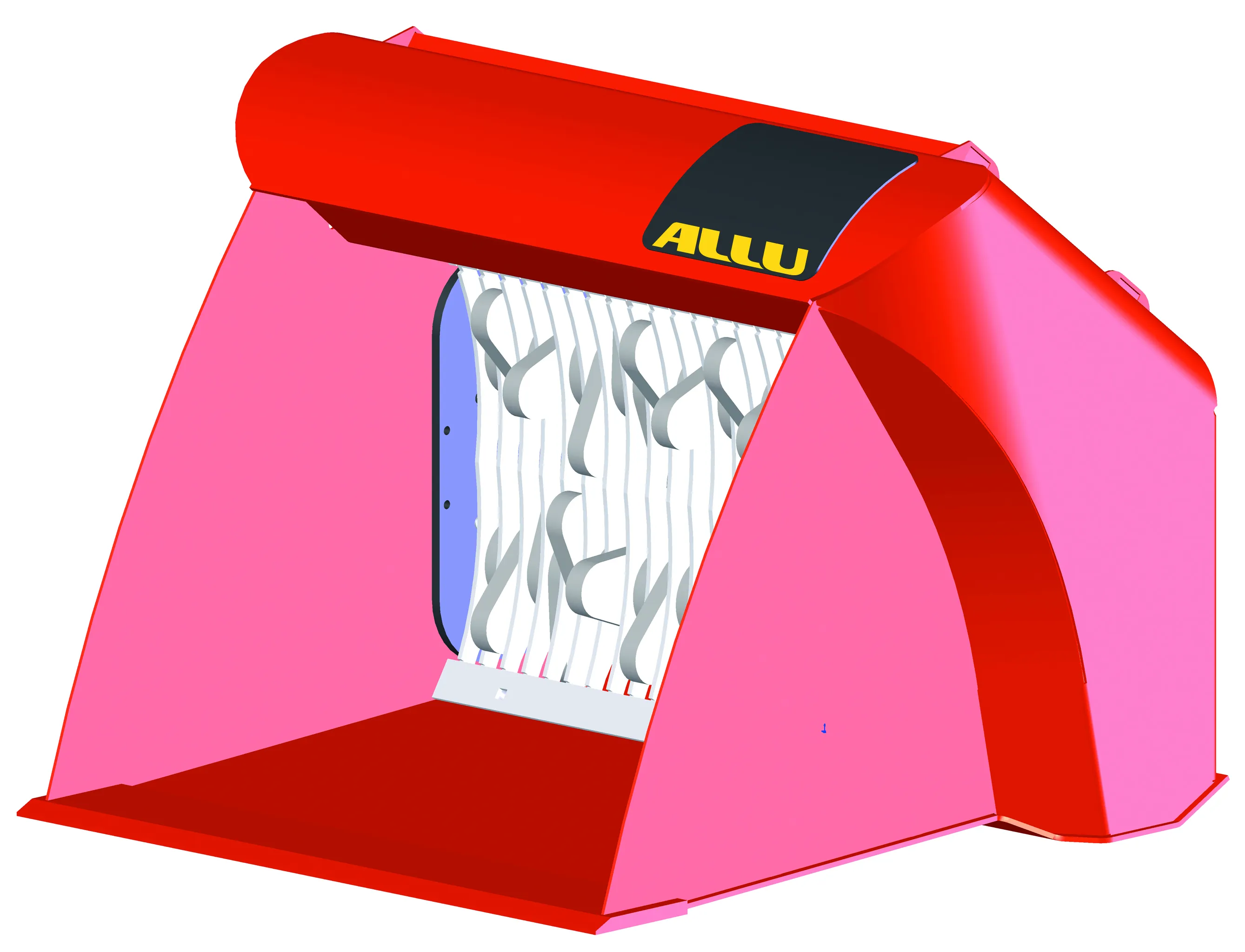

The new Allu 3D positioning system at CONEXPO is made up of four modules: computer unit with software; touch-screen; base station and GPS antennas utilising GPS signals.

January 6, 2017

Read time: 1 min

The new 2180 ALLU 3D positioning system at Conexpo is made up of four modules: computer unit with software; touch-screen; base station and GPS antennas utilising GPS signals.

The Finnish company says the new system eases the mixing work and at the same time ensures homogenous mixing results and accurate binder feeding on each cell/block in mass stabilisation.

The positioning system can be mounted on every old and new ALLU stabilisation system, a process which is carried out by feeding dry powder such as binder from a pressure feeder via a hose to the ALLU PMX mixing head mounted on an excavator. The mixing head can then be positioned to the right place on the work area with the help of the new system.

%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 48325 0 oLinkExternal www.allu.net Allu Website false /EasySiteWeb/GatewayLink.aspx?alId=48325 false false %>

The Finnish company says the new system eases the mixing work and at the same time ensures homogenous mixing results and accurate binder feeding on each cell/block in mass stabilisation.

The positioning system can be mounted on every old and new ALLU stabilisation system, a process which is carried out by feeding dry powder such as binder from a pressure feeder via a hose to the ALLU PMX mixing head mounted on an excavator. The mixing head can then be positioned to the right place on the work area with the help of the new system.

%$Linker: