The ProMet hammerless locking system includes new reversible bucket wing and blade shrouds, as well as more common weldable and bolt-on shrouds from the MTG Plus range. All have been specifically designed to extend wear life and improve performance of 30-85tonne excavator and wheeled loaders buckets.

MTG is also presenting a new range of wing and blade shrouds offering increased bucket protection and improved performance for large mining machinery: excavators (100-350tonnes) and loaders (95-250tonnes).

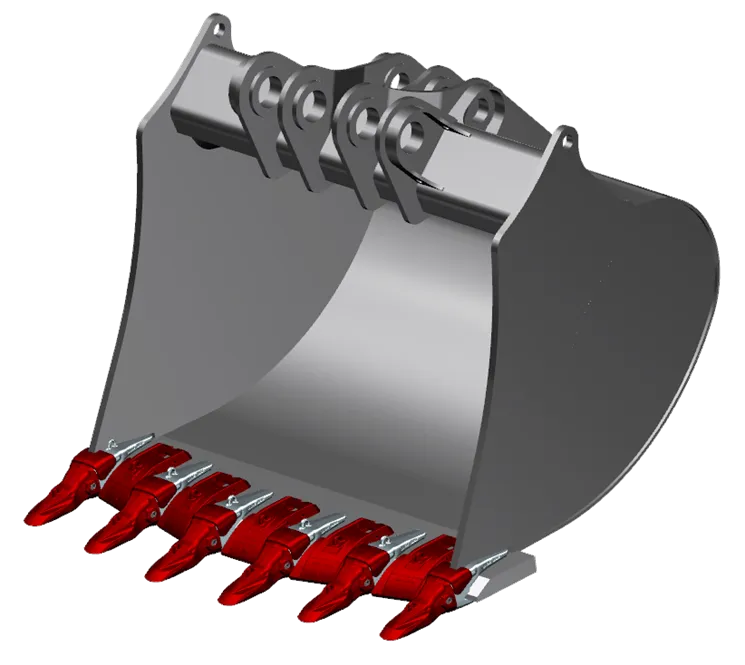

Additions to MTG’s StarMet tooth-adapter hammerless locking system for construction and quarrying buckets include a mechanical wear cap for high impact applications, a complete bottom leg shroud, and lateral adapters.

MTG will be presenting a video showcasing production processes at the firm’s Monzón factory. Stand visitors will also be able to try the IOS MTG Pro, said to be the only wear parts app for the global mining and construction machinery sectors.