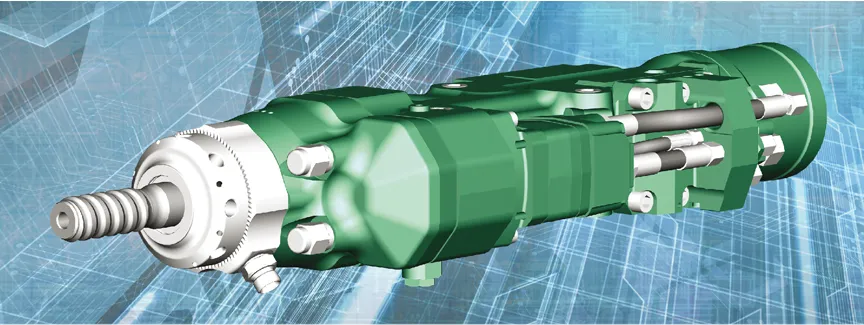

French pneumatic equipment manufacturer Montabert is launching the HC95 multi-purpose drifter, available in three versions.

Montabert’s HC95 LA can be swapped onto a machine with a minimum of effort, including mechanical and hydraulic adjustment. The ‘A’ stands for adaption, due to its multipurpose use. The shank of the new drifter can be replaced in around 15 minutes, as against an hour or so for traditional drifters which also need heavy machinery to get the job done.

There is also an HC95 LM, with the

January 6, 2017

Read time: 2 mins

French pneumatic equipment manufacturer 2396 Montabert is launching the HC95 multi-purpose drifter, available in three versions.

Montabert’s HC95 LA can be swapped onto a machine with a minimum of effort, including mechanical and hydraulic adjustment. The ‘A’ stands for adaption, due to its multipurpose use. The shank of the new drifter can be replaced in around 15 minutes, as against an hour or so for traditional drifters which also need heavy machinery to get the job done.

There is also an HC95 LM, with the ‘M’ for mining and an HC95 LQ for the quarrying sector.

Also, on the occasion of INTERMAT, Montabert will officially incorporate its Blue Line into its own Montabert products range, all under the brand Montabert. The Blue Line has five nitrogen chamber type breakers designed for use with 10-40tonne carriers.

Montabert launched the Blue Line in 2009 as entry-level equipment and now the Blue Line will trade its blue colour for the traditional green of all Montabert equipment.

Montabert’s HC95 LA can be swapped onto a machine with a minimum of effort, including mechanical and hydraulic adjustment. The ‘A’ stands for adaption, due to its multipurpose use. The shank of the new drifter can be replaced in around 15 minutes, as against an hour or so for traditional drifters which also need heavy machinery to get the job done.

There is also an HC95 LM, with the ‘M’ for mining and an HC95 LQ for the quarrying sector.

Also, on the occasion of INTERMAT, Montabert will officially incorporate its Blue Line into its own Montabert products range, all under the brand Montabert. The Blue Line has five nitrogen chamber type breakers designed for use with 10-40tonne carriers.

Montabert launched the Blue Line in 2009 as entry-level equipment and now the Blue Line will trade its blue colour for the traditional green of all Montabert equipment.