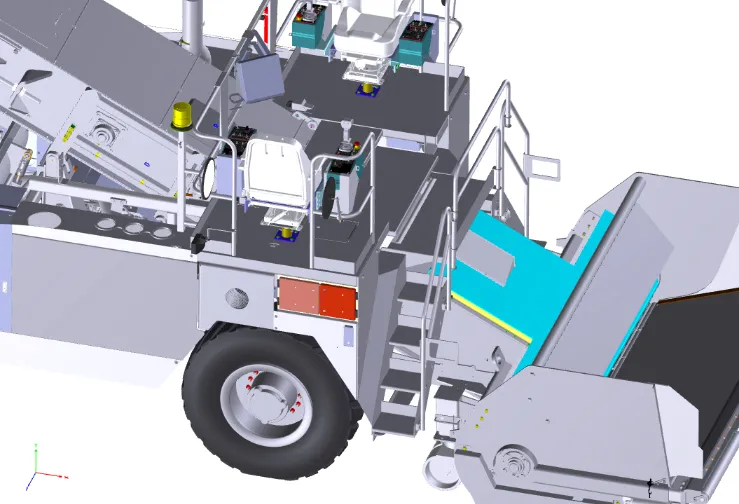

Roadtec is now developing its RX600eLR milling machine as a more versatile unit for the 2m class. The machine has been unveiled in prototype form, with full testing set to commence shortly. A key development for the RX600eLR is that the drum is driven by two hydrostatic motors, with one mounted on each side.

April 12, 2016

Read time: 2 mins

International marketing director Eric Baker said, “It can cut flush on both sides. It’s important for every market because you can’t go against traffic.” He explained that in most markets, road authorities do not allow construction machines to operate against the flow of traffic and added, “In right hand drive countries they’re fighting with that belt drive sticking out.”

The hydrostatic drives do provide benefits for the user. Baker said, “There are some advantages as you can adjust the speed infinitely and if you hit any obstructions, the hydrostatics can respond very quickly.”

He went on, “We built left hand flush cut machines before.” However this new design is more versatile and offers a much wider range of capabilities. With a standard machine it is possible to change the speed of the cutter drum by adjusting engine rpm but that approach has its limitations as it means there is a restriction on the power available. It is possible to change pulleys to adjust cutter drum speed, but this takes time and only allows a few speed options. Being able to adjust the speed infinitely allows the user to match the unit to the operating conditions. Power comes from a

This concept is more versatile and allows flush cutting alongside kerbs and New Jersey type barriers, no matter which side of the road vehicles drive on. And Baker continued, “We didn’t see the need for a slide on the cutter drum as we built the machine narrow enough and we can just crabsteer it around manholes. The drum housing is out past the outside of the machine and the tracks are set in a bit.”

The machine weighs around 30tonnes and can also be equipped with standard milling features including grade control and dust extraction.