Metso has unveiled its innovative two-in-one Lokotrack LT220D, the latest addition to its mobile crushing and screening equipment range. Claiming it to be the most compact track-mounted combination of a cone crusher and a screen ever made, the company says the combination into a single track-mounted plant will reduce operational costs in several ways, most notably by substantially lowering fuel consumption and reducing the need for maintenance. In addition, the unit is compact and highly transportable.

March 5, 2014

Read time: 2 mins

Claiming it to be the most compact track-mounted combination of a cone crusher and a screen ever made, the company says the combination into a single track-mounted plant will reduce operational costs in several ways, most notably by substantially lowering fuel consumption and reducing the need for maintenance. In addition, the unit is compact and highly transportable.

“Soaring, unstable fuel prices create demand for plants that are increasingly energy efficient and for new ways to operate. However, you can only increase the efficiency of a single machine up to a certain limit. Going beyond that point requires out-of-the box thinking and new innovations,” said Jarmo Vuorenpää, project manager at Metso Mining and Construction, describing the design process.

Metso said that the Lokotrack LT220D is designed with aggregate contractors in mind, who often haul equipment on a weekly basis while striving to keep costs down.

“The Lokotrack LT220D is the first-ever track-mounted crusher/screen combination with such compact dimensions and good transportability,” Vuorenpää continues.

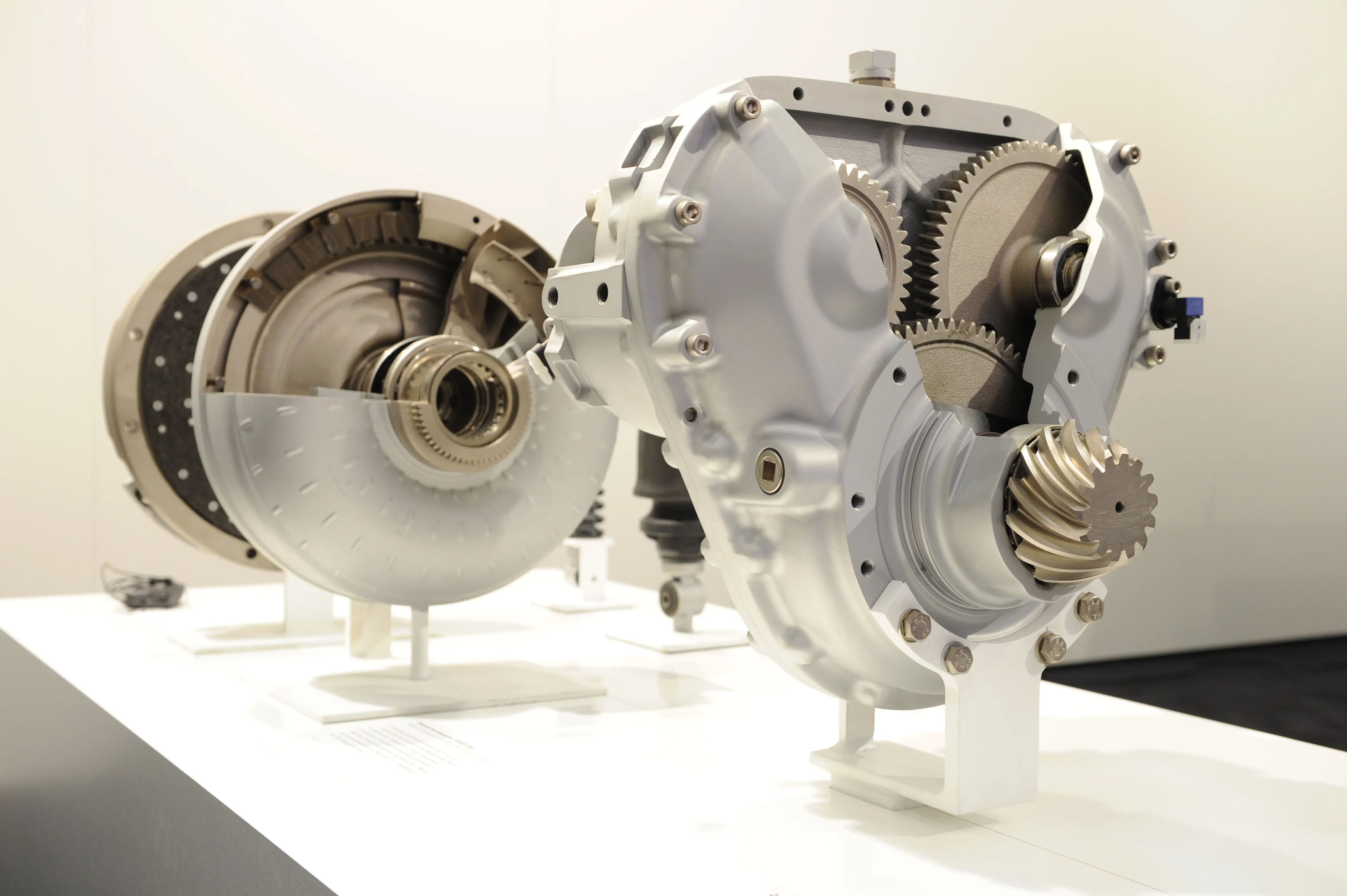

The fuel economy of the Lokotrack LT220D is the sum of several features: running both the crusher and the screen with a single Caterpillar C13 309kW diesel engine and an efficient power transmission system enables maximum power for operating.

Adrian Wood, vice president, sales support, Crushing and Screening Equipment business line, said the LT220D offered a 25% reduction in fuel consumption, requires 30% less maintenance, compact dimensions and hydraulic set-up.

“The machine has an intelligent control system; an ST4.8 screen with crusher options of GP220 or HP200 cones but the real secret is in the patented centrifugal conveyor which takes material and turns it through 180º through centrifugal force,” said Wood.

Weighing 43.5tonnes, a transport height of 3.5m and transport width of 3M, the LT220D secondary unit, when paired with Metso’s Lokotrack LT106 mobile primary jaw plant, is capable of producing up to three calibrated end products.

Hydraulically operated screen lifting and folding side conveyors enable the Lokotrack LT220D to be ready for action in minutes.

%$Linker: