This year marks a milestone for Metso as it celebrates the 40th anniversary of its novel Lokotrack mobile crushers. The Finnish technology giant is unveiling cutting-edge technology that can drive productivity and efficiency in the aggregates industry.

The new Nordberg HPe Crusher Series models are designed to improve performance and efficiency in tough environments. Also new are updates for the track-mounted crushers and screens. While introducing the new EC range models, Metso is unveiling its innovative ‘Build Your Own’ tool that allows a customer to specify a Lokotrack EC jaw or cone crusher. Another new model is the Metso HRC 8 crusher, designed to transform quarry waste streams into valuable, sellable materials such as manufactured sand.

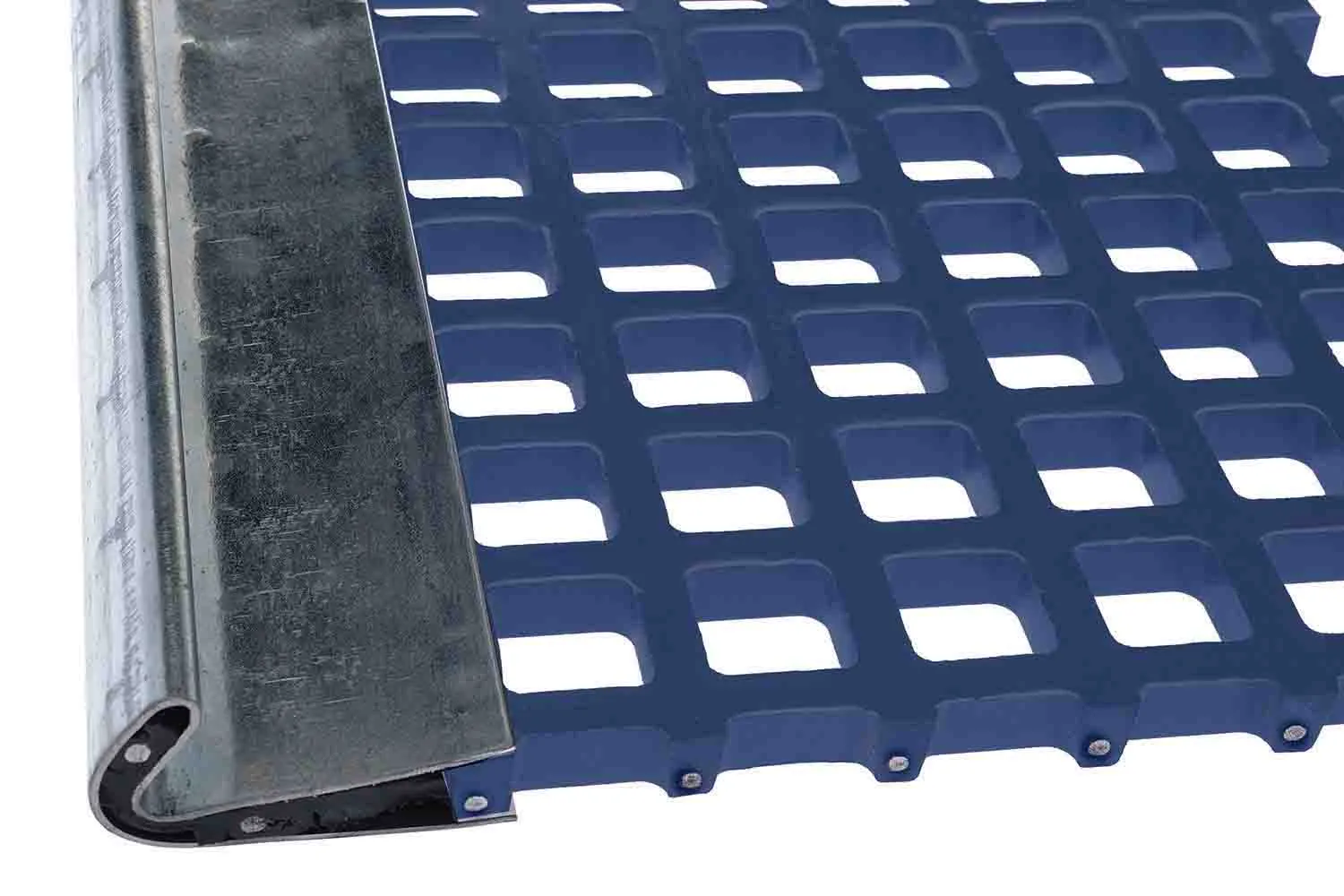

Metso is offering state-of-the-art screening technology said to ensure optimal screening performance, material separation, easy maintenance and productivity. The firm has a wide range of aftermarket solutions matching customer targets for all process stages. Innovations from Metso include new wear parts for improved lifetime and performance.

Metso offers new digital solutions to keep customer operations running smoothly and efficiently. The latest intelligent instruments and software solutions are said to enable customers to get more out of the process with less, for more profitable, efficient and sustainable production.

The firm’s quarrying solutions include tailored crushing and screening plants, and pre-designed modules and portable plants ideal for one to two years of crushing operations in one location.