The machines were working on a site for the eventual supply of power to pleasure boats on the lake and for nearby sporting events. The initiative is in line with Mecalac's commitment to promoting environmentally friendly practices, while guaranteeing optimal performance in the field and compactness together with a full eight-hour working day for electric machines.

The French company – based in Annecy - said the project is example of the energy transition that is happening within urban environments. Mecalac's three electric machines - the e12 wheel loader, eS1000 swing loader and eMDX dumper - provide emission-free operation, meeting the growing demand for more environmentally friendly equipment solutions.

Thanks to these electric machines, this worksite benefits from a significant reduction in on-site emissions, as well as lower machinery noise levels - 10 times lower than that of their traditional thermal equivalents, according to Mecalac.

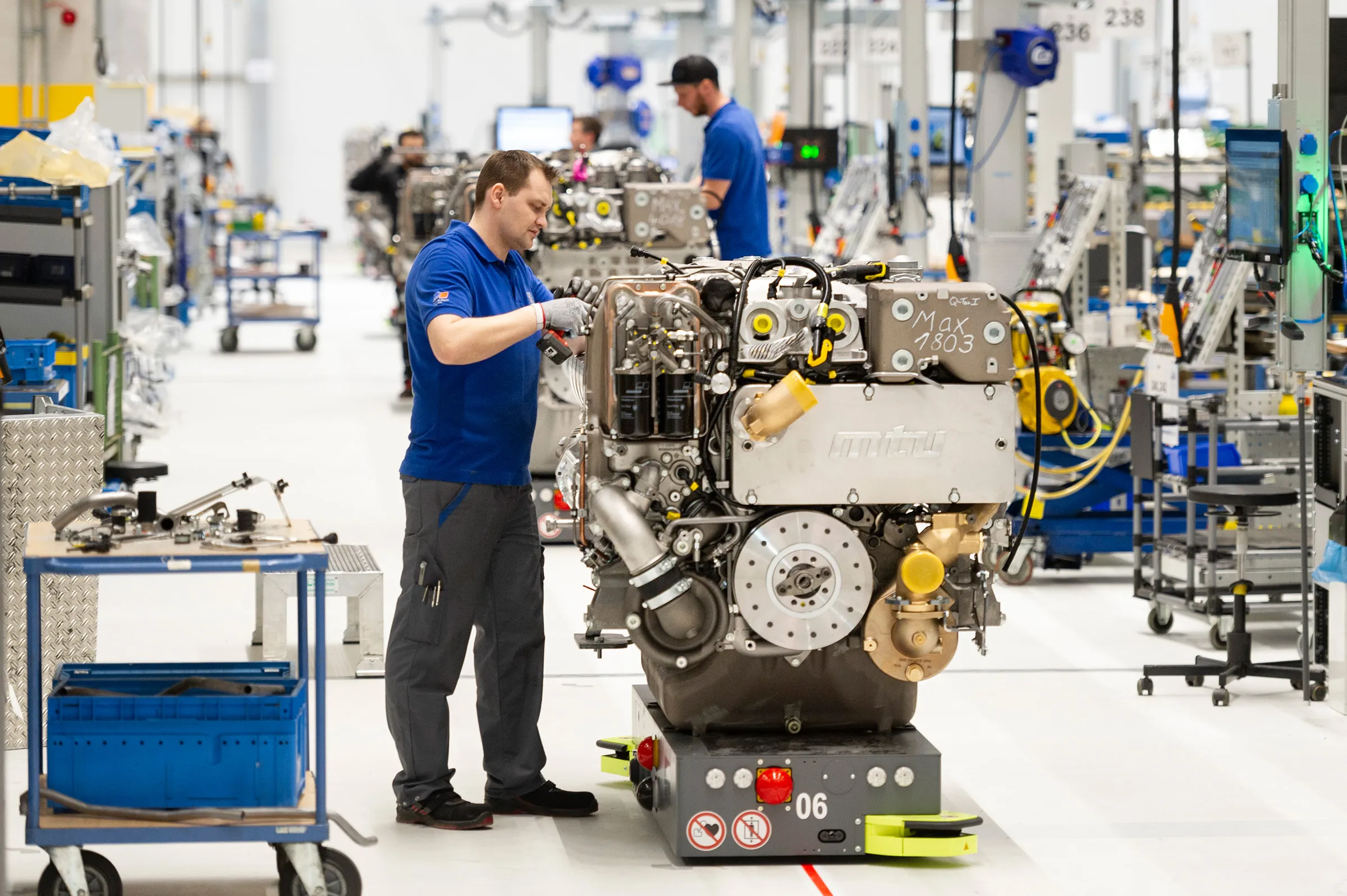

"We are proud to be taking part in this low-carbon project in a location that is particularly close to our hearts,” said Alexandre Marchetta, president of the Mecalac Group. “Our electric machines are designed and assembled locally in our Annecy plant."

Combined with other measures, such as the reuse of excavated soil, the site's projected carbon footprint is 25% lower than for an equivalent project carried out using standard methods.

The Mecalac Group, which is present in more than 80 countries, offers a wide range of excavators, wheel loaders, dumpers, backhoe loaders and roller compactors.