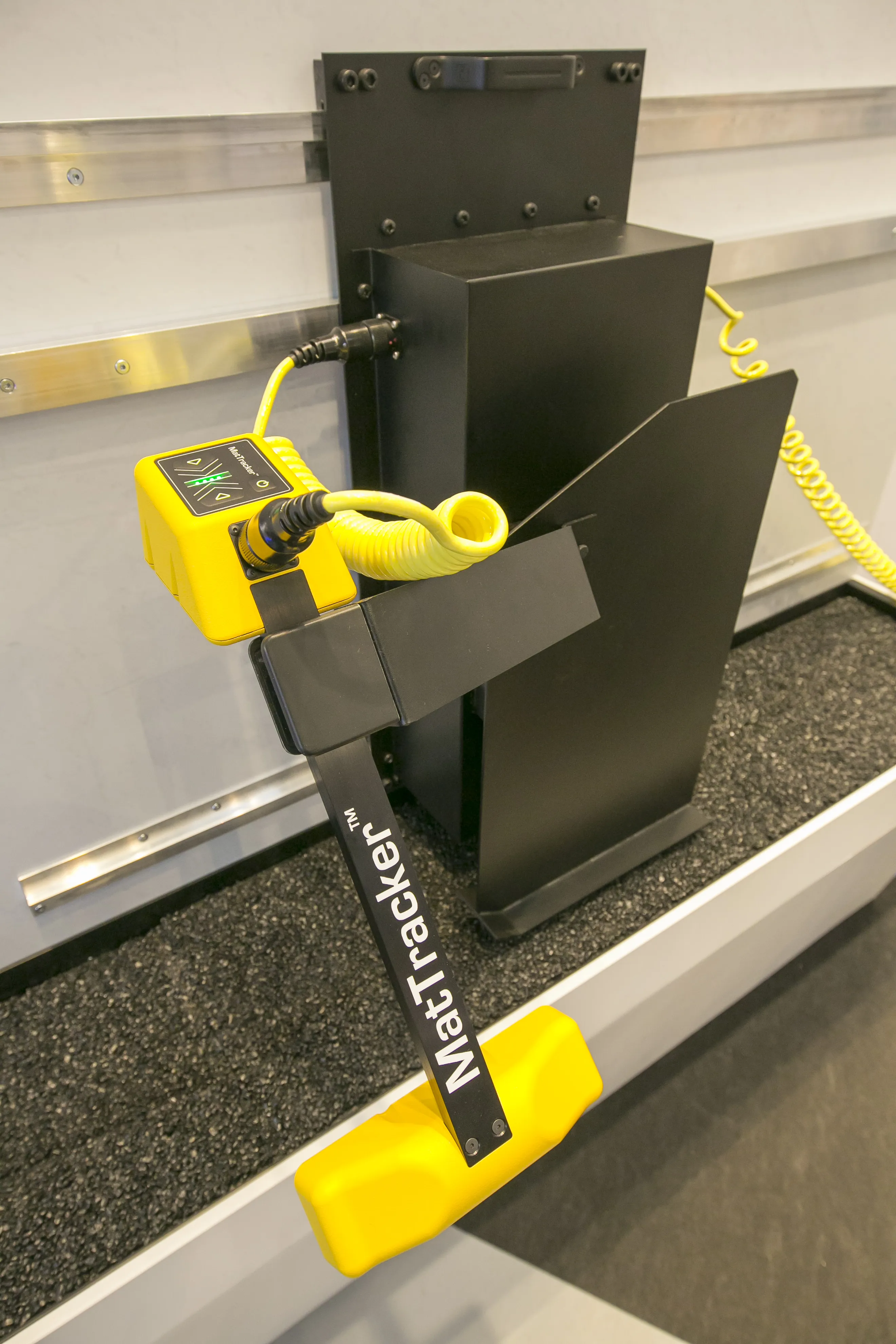

TF-Technologies which specialises in technology related to asphalt paving has invented a new means of ensuring asphalt density along the longitudinal joints between lanes. The MatTracker, developed just in time for bauma 2016, ensures that the lap width is correct and controls the position of the paver.

April 18, 2016

Read time: 1 min

“One of the critical elements in ensuring good density at joints is to ensure that you have the correct overlap,” said TF-Technologies Lisbeth Teilmann. The MatTracker uses a NIR camera and advanced image processing algorithms to follow the edge of an existing lane of paved asphalt and controls the side plate of the screed to maintain a specific overlap.

Demand from the US market, where contractors are incentivized to achieve required densities at joints, triggered this development, said Teilmann. “We plan to bring it to the market with some of the US OEMs,” she said.

Field trials of the system, which has a patent pending, were due to begin after bauma.

All videosAll show news