MAN has introduced a new design of hypoid tandem axle for payload-sensitive transport tasks, such as cement haulage.

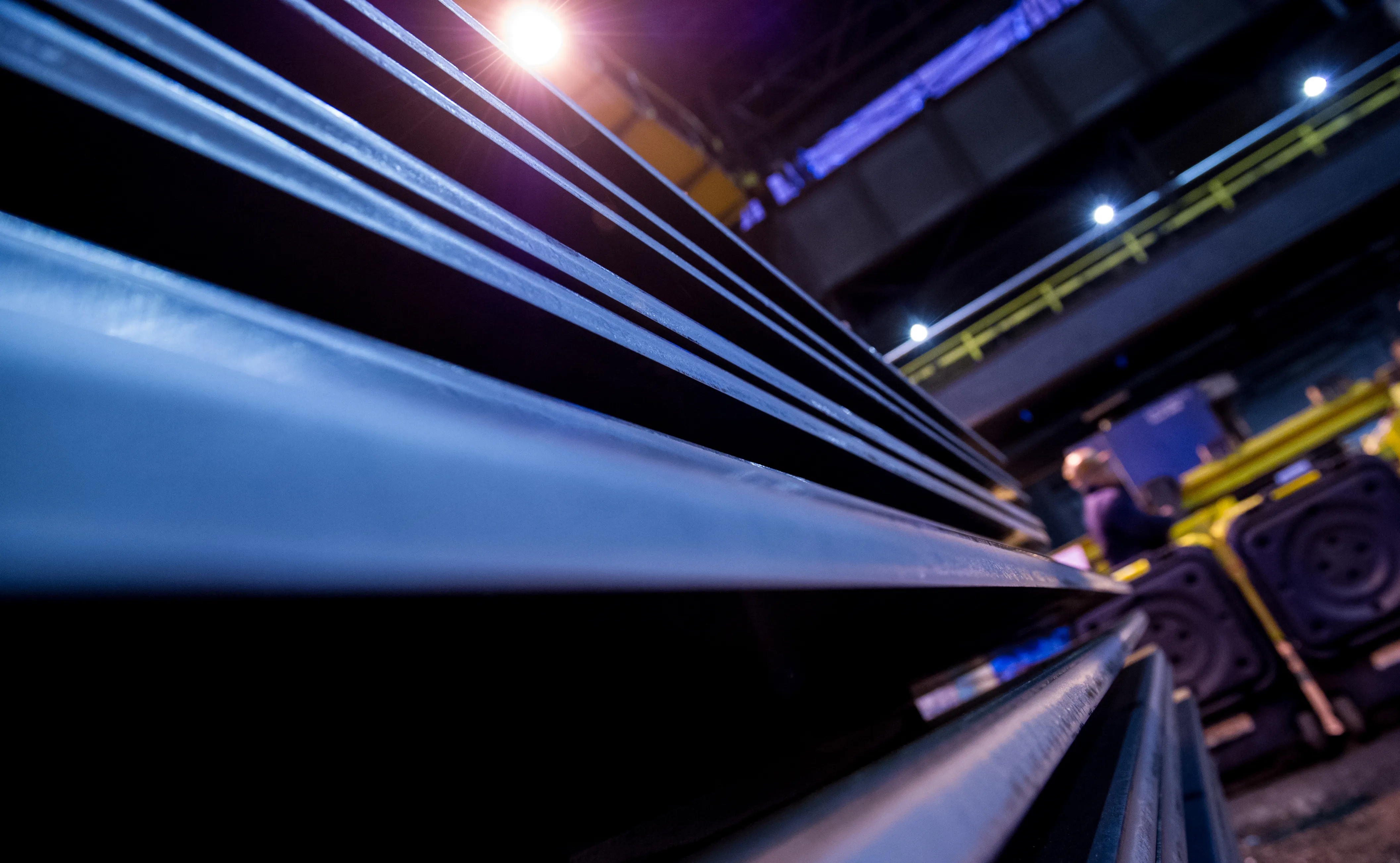

Shown on its TGS truck mixer chassis, the new axle design weighs in at approximately 280kg lighter than a conventional planetary axle, equating to greater payload potential. The four-axle MAN TGS 32.400 8x4 BB is specially designed for this purpose – it uses a weight optimised frame made of high-strength steel, a 298kW engine combined with the MAN TipMatic automated gearbox, and aluminium

April 12, 2016

Read time: 2 mins

Shown on its TGS truck mixer chassis, the new axle design weighs in at approximately 280kg lighter than a conventional planetary axle, equating to greater payload potential. The four-axle MAN TGS 32.400 8x4 BB is specially designed for this purpose – it uses a weight optimised frame made of high-strength steel, a 298kW engine combined with the MAN TipMatic automated gearbox, and aluminium wheel rims. The result is a chassis weight of 9,065kg without driver, making the most of payload potential within a gross vehicle weight of 32tonnes.

MAN’s new tandem axle design also addresses a payload shortfall with the use of thermo-insulated bodies used for transporting asphalt – choosing the lighter hypoid axle can offset payload loss from the weight of tipper body insulation, the company said.

There are other advantages from using this type of axle, it went on. Fuel consumption is claimed to be slightly lower than its trucks fitted with planetary axles, while ground clearance is higher beneath the axle – typically adding 4cm of additional clearance.

All videos