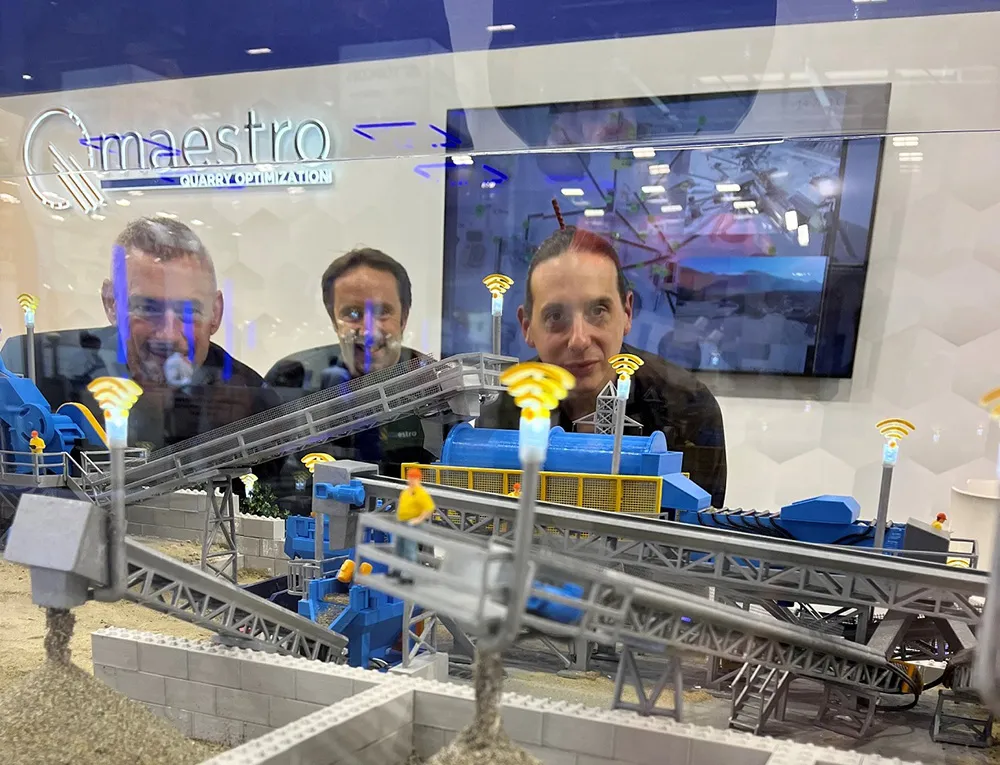

Ma-estro's new SaMoTer 2023-unveiled tool, Q-PILOT, is born out of this conviction, capturing the evolution of automation in crushing and inert recycling plants. This self-learning system monitors daily plant operations, providing operators with strategic guidance and support in making complex decisions that optimise the production cycle to its maximum potential.

By gathering comprehensive data related to sustainability and environmental impact monitoring, Q-PILOT enables operators in the quarrying sector to not only enhance efficiency but also cultivate a more sustainable and environmentally aware approach to their operations.

With an eye towards the future, Ma-estro is confident that the adoption of Q-PILOT by quarry operators will bring about a significant array of advantages:

Enhancing Decision-Making:

- Q-PILOT equip quarry operators with invaluable data and insights for more informed decision-making. Analysing historical and real-time data from various sensors allows operators to discern trends and patterns that optimise the production process. This data-driven approach leads to heightened efficiency and productivity

Facilitating Proactive Maintenance:

- The predictive maintenance tools of Q-PILOT enable operators to schedule maintenance activities based on equipment usage and performance data rather than fixed intervals. This proactive approach minimises downtime and cuts maintenance costs.

Streamlining Process Automation:

- Incorporating AI-driven automation lets quarry operators achieve superior plant control with minimal manual intervention. Q-PILOT's machine learning algorithms and artificial vision system continuously adapt and adjust processing parameters in real-time, ensuring the plant operates at peak capacity. This level of automation lets operators focus on more strategic tasks while maintaining control over the entire operation.

Enabling Collaboration:

- AI-driven innovation promotes collaboration among quarry operators, engineers, and other stakeholders. Sharing real-time data and insights enables teams to work together more effectively to optimise plant performance, troubleshoot issues, and devise new strategies. This collaborative approach helps operators stay ahead of industry advancements, spurring continuous improvement and innovation.

Supporting Skill Development:

- As AI-driven technology becomes more widespread in the quarrying industry, operators must develop new skills to stay competitive. Embracing AI-driven tools like Q-PILOT allows operators to gain valuable experience working with advanced technology and machine learning algorithms. This skill development enhances operators' expertise and bolsters their value within the industry.

Energy and Resource Optimisation / Emission Reduction:

- Q-PILOT's intelligent algorithms help operators identify and implement energy-saving strategies, optimise fuel and energy consumption, reduce idling times, and ensure equipment operates at peak performance to minimise emissions. This results in lower energy consumption, reduced water usage, minimised waste, and a cleaner environment, contributing to a more sustainable operation.

Environmental Stewardship:

- By prioritising sustainability and diminishing environmental impact, operators can satisfy regulatory requirements and improve their reputation and relationships with local communities and stakeholders.

Ma-estro says adopting Q-PILOT is a "paradigm shift" that promotes a more sustainable and environmentally conscious approach while ensuring that human expertise remains at the forefront of industry advancements.

"This new system, now more standardised with a switch from PLC Logic to PC Logic, offers greater accessibility to new customers," says Giorgio Manara, Ma-estro's CEO and sales manager. "Q-PILOT requires fewer sensors and involves less invasive interventions, making it an ideal choice for quarry operators seeking a user-friendly solution. While it seamlessly integrates with our existing Ma-estro solutions, it is equally designed to cater to the needs of new customers, providing them with a streamlined and efficient plant control system."

Q-PILOT has been recognised for its cutting-edge innovation, winning the prestigious 2023 Samoter Innovation Award in the Software applications & plants category.

"We did not want this system to give you orders; we wanted it to give you advice on managing your plant," stresses Marco Resta, Ma-estro's marketing strategist. "With this tool, it widens our potential customer base."

Before its launch, Q-PILOT was thoroughly tested at Manara's quarry near Ma-estro's Rovereto, northeast Italy HQ. The tool was showcased as part of the SaMoTer Lab project at this year's 31st edition of SaMoTer (3-7 May 2023) at the Verona Exhibition Centre. It will be used at a quarry participating in the EU DIGIECOQUARRY project, aiming to tap the full potential of 'Digital Quarries' through a significant breakthrough in process digitalisation and automation capabilities for the aggregates sector.

"We are planning to have it installed soon on a client plant," says Resta. "We are initially going to implement this system only in quarries. It will be fully available to customers in 18 months to two years."

Ma-estro was established by Manara in 2006 after the entrepreneur devised a technological solution to control his crushing plant's previously varying daily product costs, realising that other crushing contractors and quarry operators could also benefit from using the same technology. Fast-forward 17 years, and the company is growing its global footprint for quarrying optimisation solutions.

"As well as in Italy, we have installations in India, Brazil and North Africa," highlights Manara. "We are also looking to go into France and northern Europe. The great thing about Q-PILOT is that a local dealer can manage it rather than needing it to be managed by us from Italy."

A member of ANEPLA (Associazione Nazionale Estrattori Produttori Lapidei Affinia), the Italian aggregates federation, Ma-estro wants to widen its Italian customer base. "We are looking to offer our products in southern Italy, and one of ANEPLA's two big annual events this year will be in Bari, Puglia. We hope to gain as much interest as possible from quarry operators in the south.

"Alongside the launch of Q-PILOT, we are upgrading our web portal. This will gather data from all quarry machines and give customers data on fleet sustainability, supplying real environmental action point numbers. We will use a blockchain to protect this data. In the near future, all companies will pay great attention to this. There will be tax incentives offered to be more sustainable. Optimising your energy usage, for example, can reduce your energy consumption by 20%."