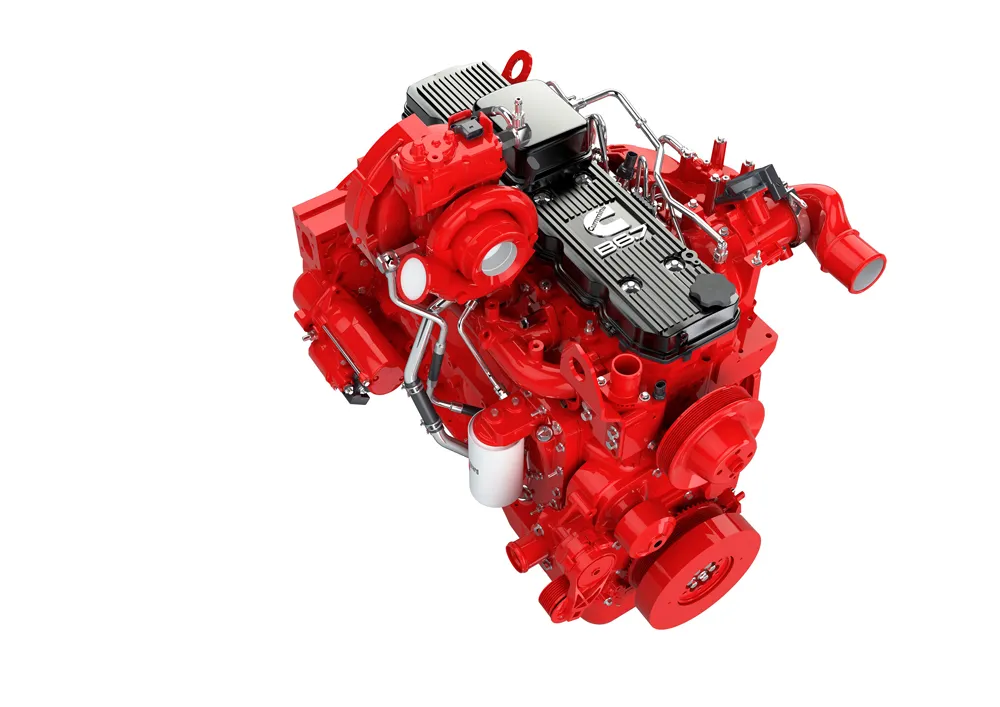

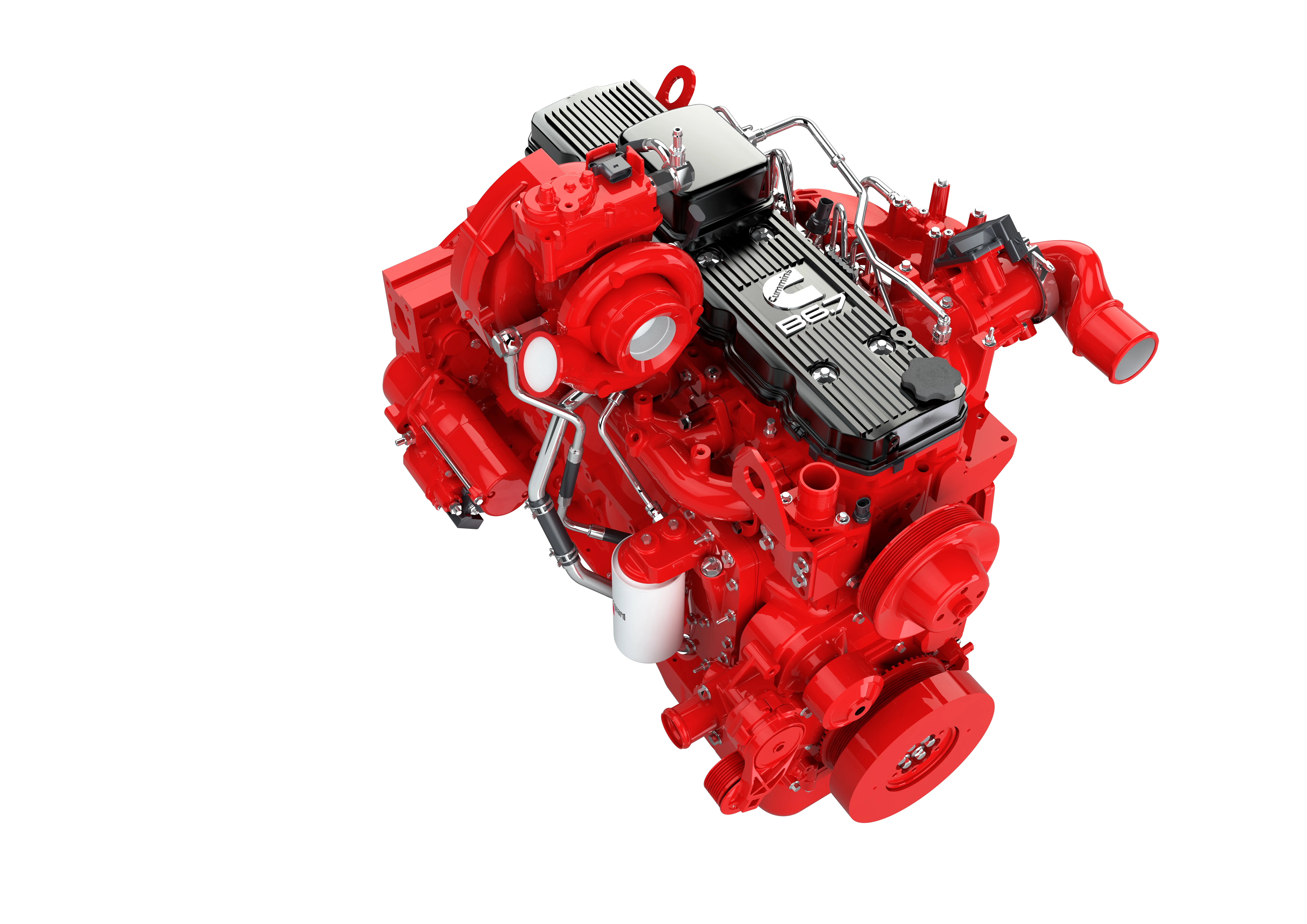

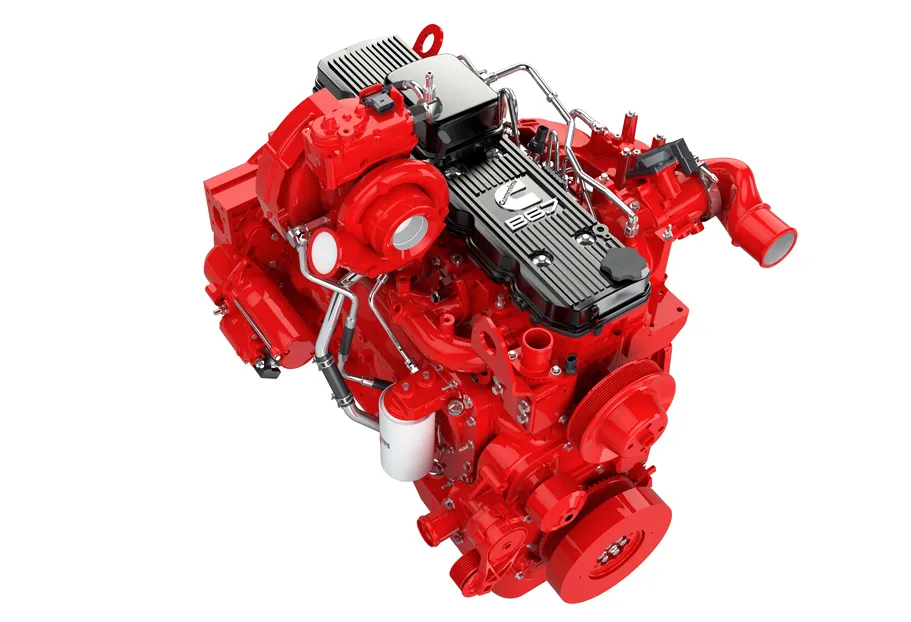

The B6.7 engine is suited to installations in crushers, screeners, wheeled loaders and excavators. The firm says that the engine also features stop-start capability which can help reduce running costs, as well as environmental impact, through lower noise and CO2 emissions.

Jeremy Harsin, Cummins off-highway business director, said: “Stop-start capability is included in the B6.7 to further cut fuel consumption as well as overall maintenance costs. Fuel savings should be between 5 and 10% but could be higher based on the machine duty cycle. This feature also delivers the sociability benefits that contractors are looking for by reducing onsite noise and exhaust emissions. Improving fuel efficiency reduces CO2 greenhouse gas emissions.”

Cummins says that stop-start has been integrated into the B6.7 platform with both hardware and software changes. Specially developed bearings in the engine, along with upgrades to the flywheel ring gear and starter motor, are designed to ensure long life and reliable performance with frequent starts.

The company adds that its engineers work closely with the OEM customer to integrate the engine electronic control module (ECM) software with machine controller software. The OEM controller monitors the machine operation and communicates to the ECM when it is appropriate and safe for the machine to shut off.

The ECM monitors engine parameters such as coolant temperature, intake manifold temperature, engine load, and fan operation to make sure it is safely able to shut down. When all criteria are met, the engine will stop. The machine controller will then request an engine restart when required, and the ECM automatically restarts the engine to continue working.

The B6.7 engine is available from 116-243kW with a high peak torque of 1,375Nm. It offers a low weight and compact size, delivering a high power density that allows users to replace engines of higher displacement with no impact on machine operation. This supports machines needing higher speed power delivery, with low-end torque capability for transient performance benefits.