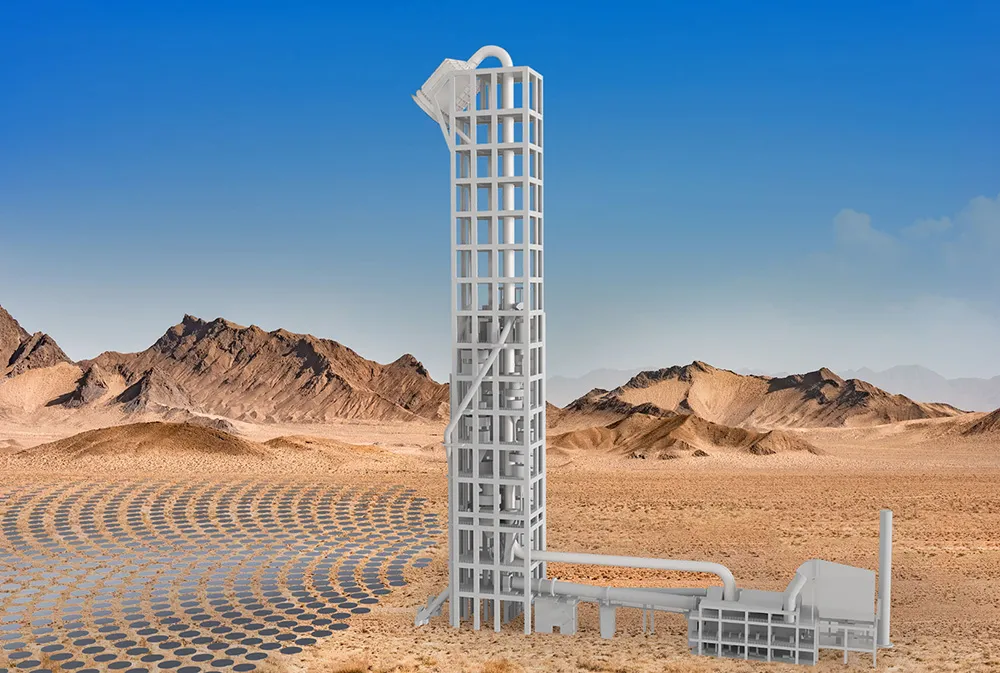

A new, patented Aggregates Cooling System (ACS) was one of the main taking points on the stand of asphalt and concrete plant manufacturer Lintec at Conexpo. Lintec has just sold its first ever plant to concrete manufacturer Emirates Beton in Dubai. When mixing concrete in warm climates, aggregate has to be cooled in order to maintain the performance and quality of the finished product, explained Lintec managing director Carsten Weiss: “If you don’t cool it, you don’t get the strength at the end,” he said. “

January 6, 2017

Read time: 2 mins

A new, patented Aggregates Cooling System (ACS) was one of the main taking points on the stand of asphalt and concrete plant manufacturer Lintec at Conexpo. 1177 Lintec has just sold its first ever plant to concrete manufacturer Emirates Beton in Dubai.

When mixing concrete in warm climates, aggregate has to be cooled in order to maintain the performance and quality of the finished product, explained Lintec managing director Carsten Weiss: “If you don’t cool it, you don’t get the strength at the end,” he said. “And that is vital if you are constructing a dam for a big hydroelectric project or a skyscraper.”

The standard method for cooling aggregate is to use ice, but producing the ice demands lots of energy. By using the ACS, which can be fitted to new or existing plants, manufacturers can save 50% on energy costs, according to Weiss. “We are talking about substantial amounts of money here,” said Weiss.

Lintec signed up a US dealer for its ACS at the Conexpo show and is looking for others in North America.

The manufacturer was also displaying its warm mix asphalt (WMA) technology LEP (Lintec Ecological Processing). This system uses foamed bitumen to reduce the mix temperature from 180°C to 100°C, resulting in energy savings, less carbon emissions and less emissions of other harmful gases.

Lintec has a strong market in South America, with a subsidiary in São Paolo. Many South Americans had visited the stand, said Weiss.

www.lintec-gmbh.de

When mixing concrete in warm climates, aggregate has to be cooled in order to maintain the performance and quality of the finished product, explained Lintec managing director Carsten Weiss: “If you don’t cool it, you don’t get the strength at the end,” he said. “And that is vital if you are constructing a dam for a big hydroelectric project or a skyscraper.”

The standard method for cooling aggregate is to use ice, but producing the ice demands lots of energy. By using the ACS, which can be fitted to new or existing plants, manufacturers can save 50% on energy costs, according to Weiss. “We are talking about substantial amounts of money here,” said Weiss.

Lintec signed up a US dealer for its ACS at the Conexpo show and is looking for others in North America.

The manufacturer was also displaying its warm mix asphalt (WMA) technology LEP (Lintec Ecological Processing). This system uses foamed bitumen to reduce the mix temperature from 180°C to 100°C, resulting in energy savings, less carbon emissions and less emissions of other harmful gases.

Lintec has a strong market in South America, with a subsidiary in São Paolo. Many South Americans had visited the stand, said Weiss.

www.lintec-gmbh.de