Adel Abu Sal & Sons, a leading road construction contractor in Jordan, recently purchased a Lintec CSD2500B containerised asphalt mixing plant supplied by Lintec & Linnhoff’s dealer, Jordan Tractor and Equipment.

The installation and commissioning process of the Lintec CSD2500B plant was completed in just one month, including delivery, testing, and full operational setup, allowing the plant to begin production swiftly. Jordan Tractor is also responsible for plant maintenance to ensure productivity and machine uptime are maintained to the highest possible levels.

The Lintec CSD2500B is being used for three major road construction projects run by the company, with more lined up. The first project started in May 2024 in collaboration with the Greater Amman Municipality and involves the construction of 500,000m2 of roads across the outskirts of Amman. The second project, also with Greater Amman Municipality, began in July 2024 and focuses on 800,000m2 of main road development, with ongoing night shifts to expedite completion. The third project, set to begin in April 2025 for Mafraq Municipality, will cover 250,000m2 of main roads, with completion planned 30 working days after the start.

Transport infrastructure in Jordan is undergoing a huge transformation, with investment opportunities emerging in every sector. These projects are geared towards making the most of Jordan’s growing potential and its prime geographical location as a central transport and logistics corridor for the region.

Installation and commissioning took just one month and, operational since January 2024, the Lintec CSD2500B has produced 80,000tonnes of asphalt to date. This asphalt has been used on a mix of new build and refurbishment highway projects.

Transport remains the lifeblood of the economy in Jordan, connecting the main port in the south with the capital and larger cities in the north. The Lintec CSD2500B has already had a significant impact on this, improving infrastructure and facilitating better connectivity to boost economic activity and enhance the quality of life for the local population.

Tareq Asa’d, Construction Machines sales manager, Jordan Tractor said: “The Lintec CSD2500B asphalt plant offers high productivity, low fuel consumption, and efficient containerised design. These features make it a perfect choice for our road construction projects in Jordan. We’ve been really impressed with it and are considering further purchases as our workload continues to grow.”

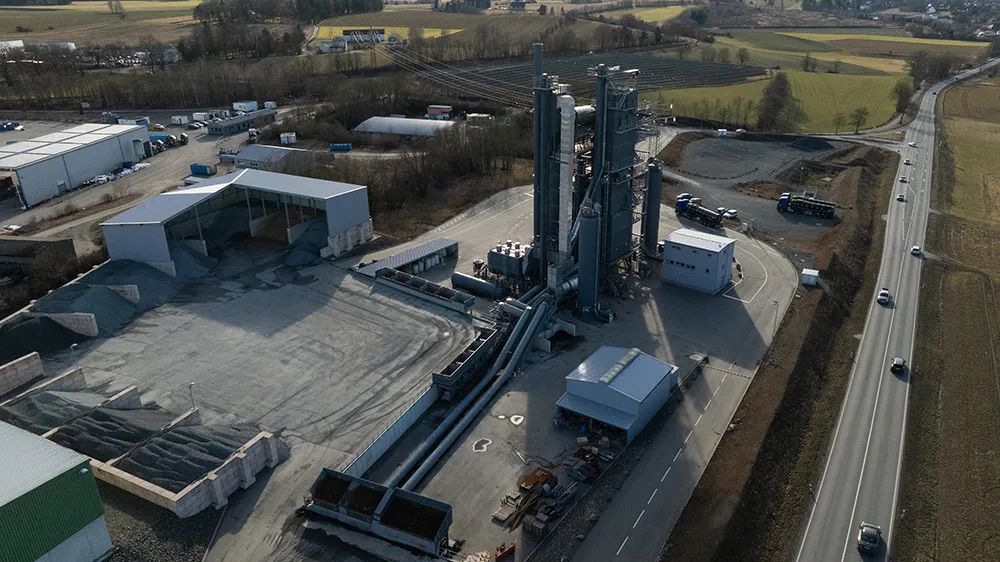

The modular design of the Lintec CSD2500B, built i standard containers, lends itself to efficient, economical transportation, and makes the plants ideal for short- and long-term projects. Their flat, rigid design also speeds up installation by eliminating the need for concrete foundations on suitably compacted soil. This asphalt plant features a single lockable main access point for improved onsite security. This containerised concept also means reduced dust and noise emissions.

In addition, Lintec’s novel double screen drum technology eliminates the need for a hot elevator and vibrating screens which in turn reduces maintenance requirements. Combining the heating and screening of the minerals in a single process unit offers significant energy savings.