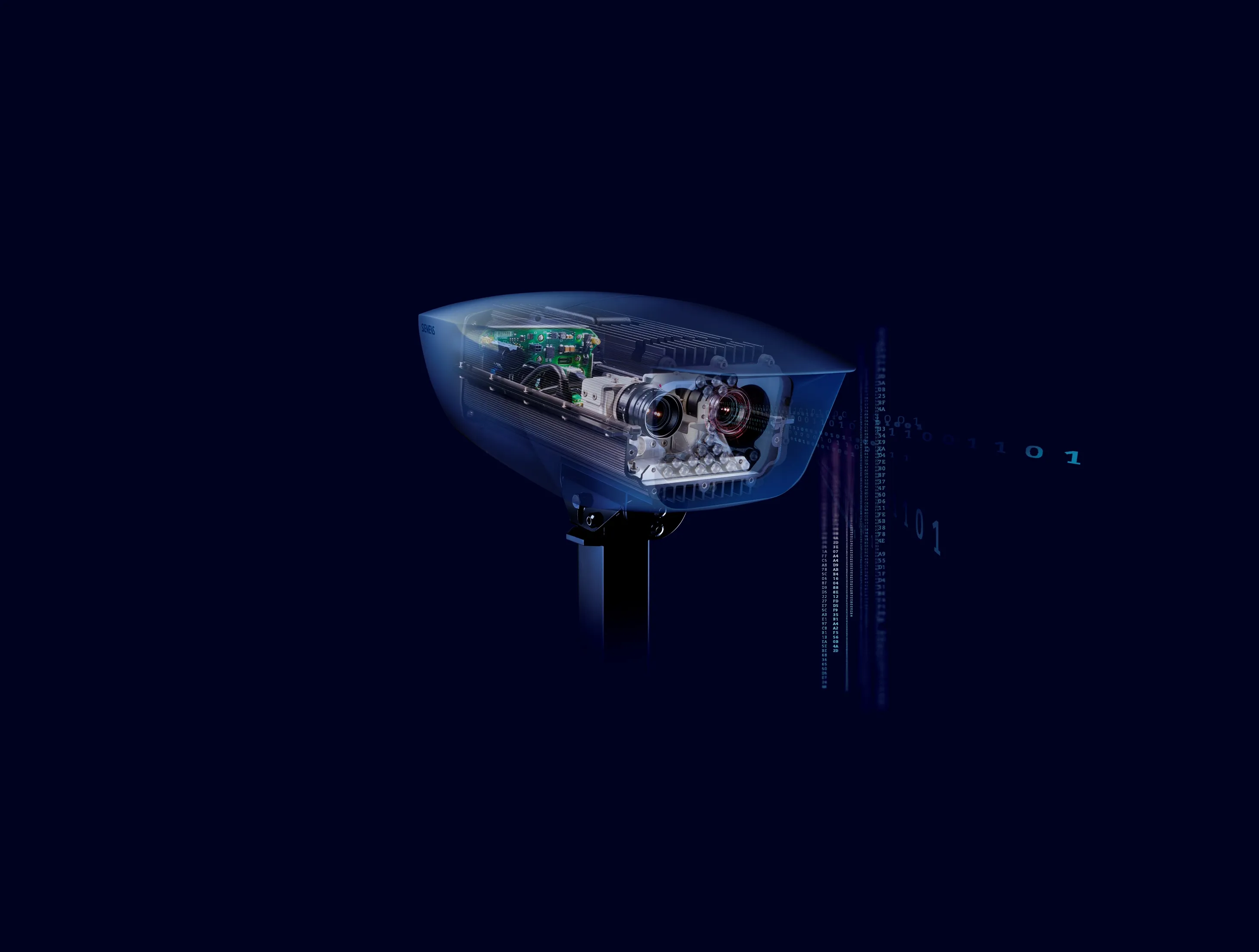

The ILCAM2 - part of the TLACS (tunnel lighting addressable control system) solution - measures the level of illuminance within road tunnels and underpass bores to ensure interior light levels are continuously maintained to improve lighting conditions for drivers.

The ILCAM2 is used in road tunnels within the TLACS-EM system and in underpasses with the TLACS-U. It sends the illuminance values to a lighting control cabinet using power line communication on existing power cables.

The ILCAM2 uses a highly light-sensitive photocell – silicon photo diode - filtered to provide a spectral response close to that of the average human eye in order to react to changes in light levels within the tunnel environment. The unit measures the illuminance over a standard range of 0-20,000 lux (maximum), which can be scaled to meet user requirements.

The unit is contained in a rugged painted stainless steel 316 container and has an operational temperature range from -30ºC to +70ºC. It is also CIE and IES approved or measurement technology.

Power line communication doesn't require the installation of additional control wires for control and monitoring: it uses the existing powerline cables. This means important savings on the installation time, on wires and connectors and on maintenance of the lighting system.

“With over 30 years in developing power line applications, it was obvious for Nyx’s team to improve its ILCAM with a power line version,” said Pierre Longtin, president of Nyx Hemera Technologies, based in Quebec City, Canada. “The ILCAM2 was created mainly for long tunnels as it helps save on installation time, related manpower and the cost of cables that could run for miles in such infrastructure.”

The unit is contained in a rugged painted stainless steel 316 container and has an operational temperature range from -30ºC to +70ºC. It is also CIE and IES approved or measurement technology.