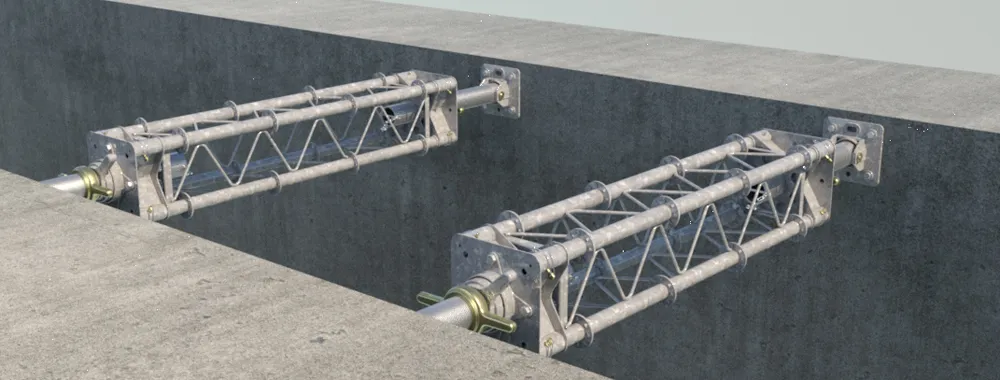

The system’s 400kN loading capacity means a minimum number of props are required, helping to reduce costs and assembly time. At the same time, says RMD, it has been designed with lightweight components, so the product can be easily carried by workers, with no need for a crane.

With a weight of only 30kg/m, Tetrashor delivers an excellent strength-to-weight ratio, according to the company.

Tetrashor’s versatility is a key feature. It can be used horizontally, vertically or inclined. The Tetrashor prop can also be used as a group of four to create a Tetrashor tower, providing a loading capacity of up to 1600kN for heavy, concentrated loads.

Tetrashor is compatible with RMD Kwikform’s range of falsework systems, including Megashor, Rapidshor and Superslim and is available in five prop variants to suit most applications.

The system also features an innovative KwikStrike load release mechanism for workers to release loads in a quick and controlled manner. With other systems, removing loads can be a long and exhausting process but testing has proven that activating KwikStrike requires only two or three hits from a hammer. RMD says that this not only reduces labour and time, but it minimises noise, safety risks and damage to equipment.

A range of hydraulic jacking options are available, enabling the controlled application, monitoring and release of loads should the application demand precision, explained Ian Fryer, divisional product innovation director at RMD Kwikform. “When superior prop strength is a key requirement, the compromise is generally a heavier system that is more difficult to manoeuvre. Conversely, lightweight but less strong systems often require more materials to meet loading capacities, adding to erection times and costs,” he said.

“With Tetrashor, contractors do not have to compromise. Tetrashor provides a safe, cost-effective and efficient solution, helping to overcome common industry challenges by supporting heavy loads, while also improving productivity through its versatility and design. For instance, less bracing is required on longer props than alternative solutions, helping contractors to keep costs down,” said Fryer..