Liebherr’s PR 756 Litronic crawler tractor is one of two new models in its now three-strong Generation 6 crawler tractor programme.

Like the PR 736 and PR 746, the PR 756 is Stage IV engine emission standard and offers a six-cylinder 250kW engine. The model’s operating weight ranges from 38.3-41.15tonnes.

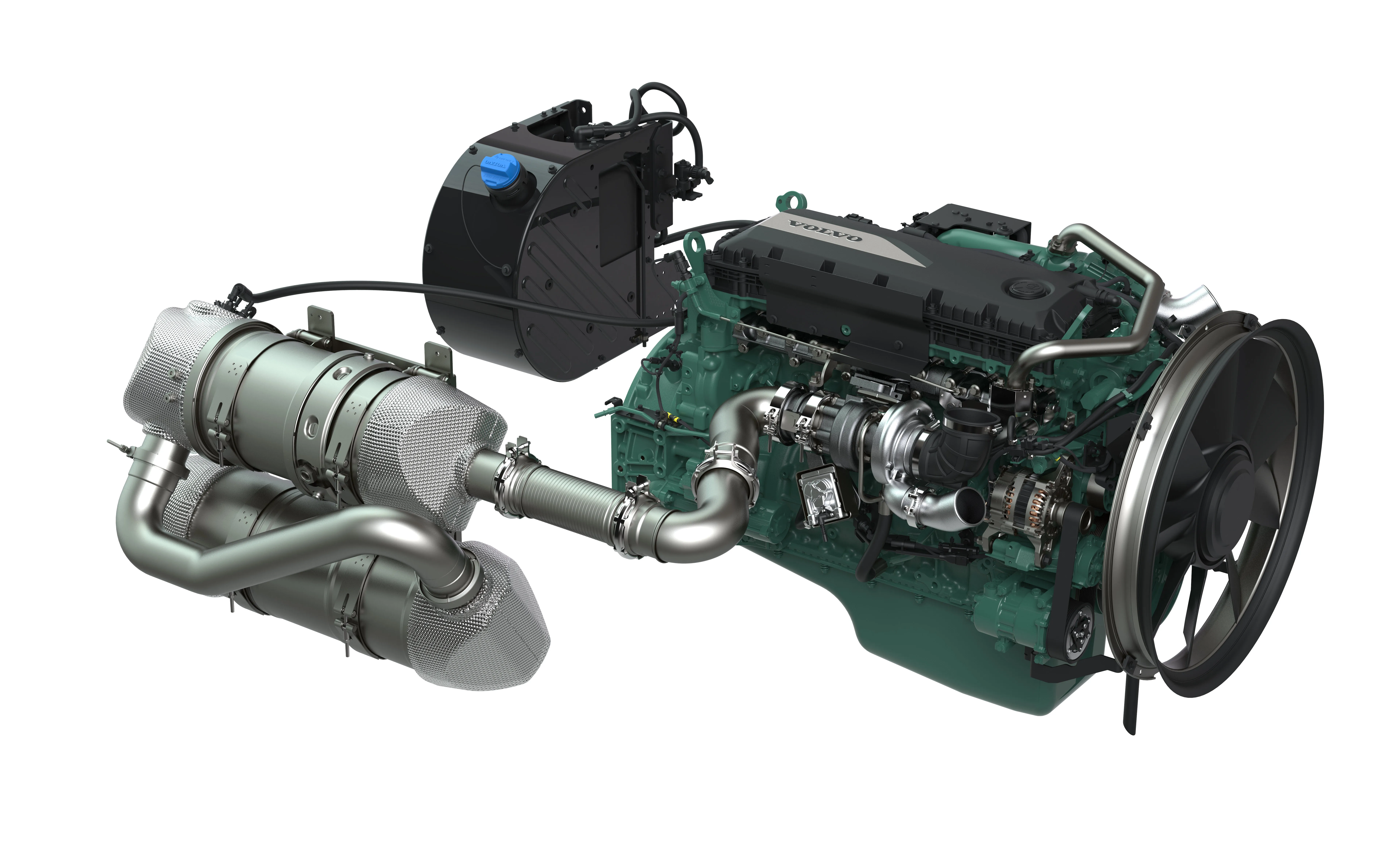

The main components of the PR 756 come from Liebherr’s own production facility. Among these are the diesel engine and the common rail injection system as well as the hydraulic and electronic components.

February 19, 2015

Read time: 3 mins

Like the PR 736 and PR 746, the PR 756 is Stage IV engine emission standard and offers a six-cylinder 250kW engine. The model’s operating weight ranges from 38.3-41.15tonnes.

The main components of the PR 756 come from Liebherr’s own production facility. Among these are the diesel engine and the common rail injection system as well as the hydraulic and electronic components. These are adapted optimally to the requirements of the machine programme. Here, Liebherr can draw from over 50 years of experience in the development of crawler tractors.

In order for the requisite engine emissions and consumption targets to be fulfilled, Liebherr has optimised the entire combustion process and has already reduced the particulates within the PR 756’s engine to a minimum. For ideal adaptation of the various parameters, support is provided, among other things, by the development of an in-house common rail injection system including an in-house electronic engine management system.

To simplify the system and to optimise exhaust gas after treatment for challenging operations, selective catalytic reduction (SCR) technology and a diluted urea solution (AdBlue) is employed. The efficient combustion in turn facilitates lower fuel consumption and provides cost saving benefits to the customer.

Like the PR 736 and PR 746, the PR 756 Litronic crawler tractor features a newly-developed, electronically-controlled drive management system with integrated ECO function. This enables the driver to choose between high performance and maximum economy. Here, compared with the previous generation, the ECO control system ensures more efficient operation of the travel drive for light to medium-heavy operations.

Another impressive new feature of this Generation 6 model is its proactive power control. With it, internal engine parameters as well as external machine parameters are detected, such as the current degree of drive joystick deflection, resulting in engine performance being elevated automatically for a short period to match the current demand. As well as responding more rapidly, the machines are said to offer a tangible increase in performance potential and pulling power.

This hydrostatic drive keeps the engine speed at a constant level. All of the drive components and the intelligent Liebherr engine management are harmonised optimally to each other. The Liebherr travel drive is distinguished by a high level of efficiency and low fuel consumption.

To simplify the use of automatic machine control systems, Liebherr supplies ex-factory preparation kits for leading manufacturers’ systems; these kits are also available for Generation 6 crawler tractor models. This makes it significantly easier to install 2D and 3D control systems and affords the operator the highest level of flexibility in choosing the system.

The modern design of the PR 756 Litronic crawler tractor, with its falling edges on all sides and uninterrupted panoramic glass pane, offers the driver an optimal all-round view of the terrain as well as the blade and rear ripper.