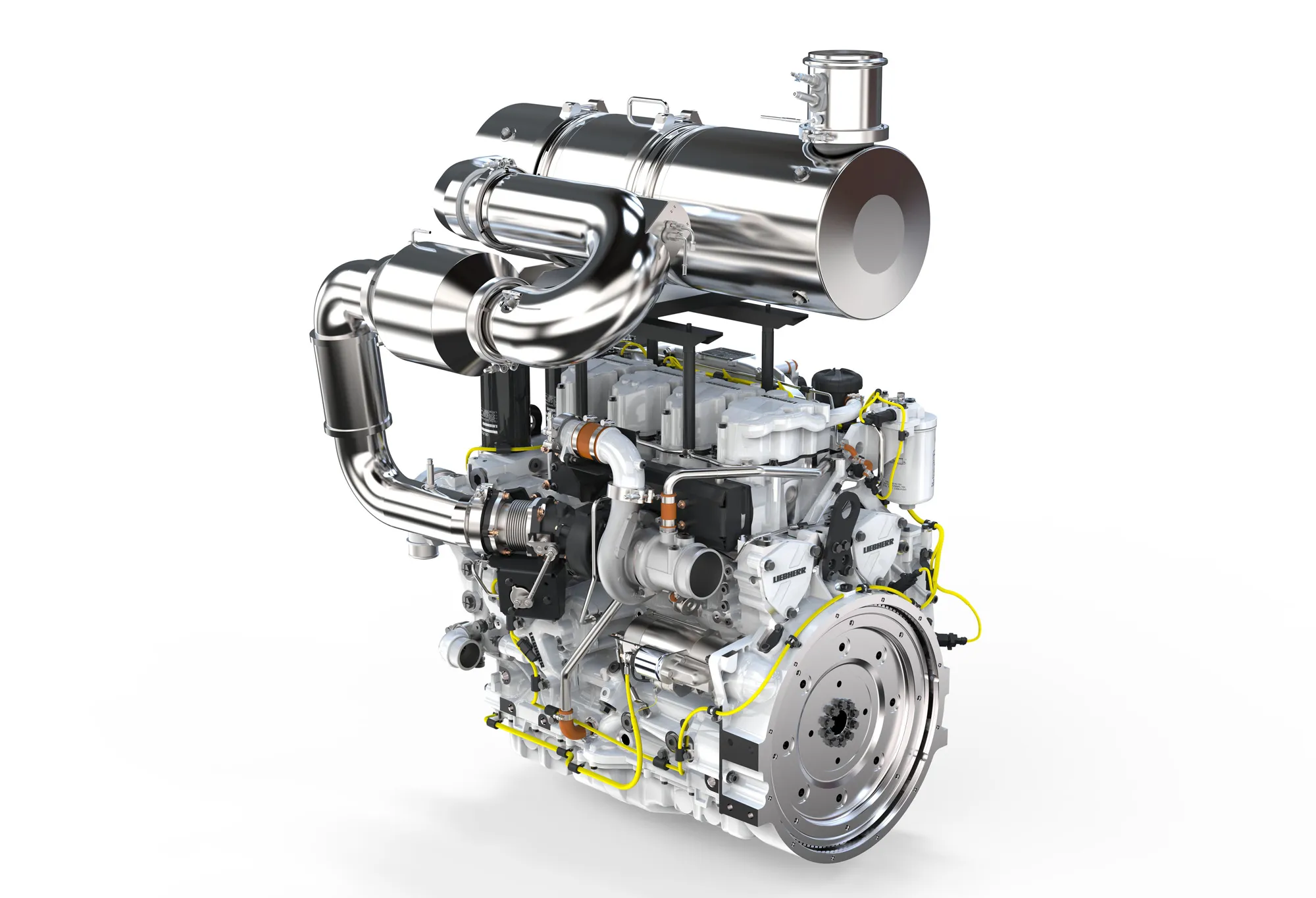

Liebherr’s innovative SCRFilter is a sophisticated exhaust-gas-aftertreatment system for diesel engines designed to meet Europe’s coming stage V requirements. This compact system combines SCR catalytic converter and particulate filter, using proven technology already tested in machines for tunnel construction. The exhaust-gas-aftertreatment system forms part of the modular Liebherr engine concept for every emission standard and offers long service intervals of over 4,500 hours.

March 7, 2016

Read time: 2 mins

Liebherr fitted its first machines with the SCRFilter system in 2014. Since mid-2015 the system is being installed in end devices as standard. An exhaust-gas-aftertreatment system, which has already been tried and tested in the field, is thus, available to customers.

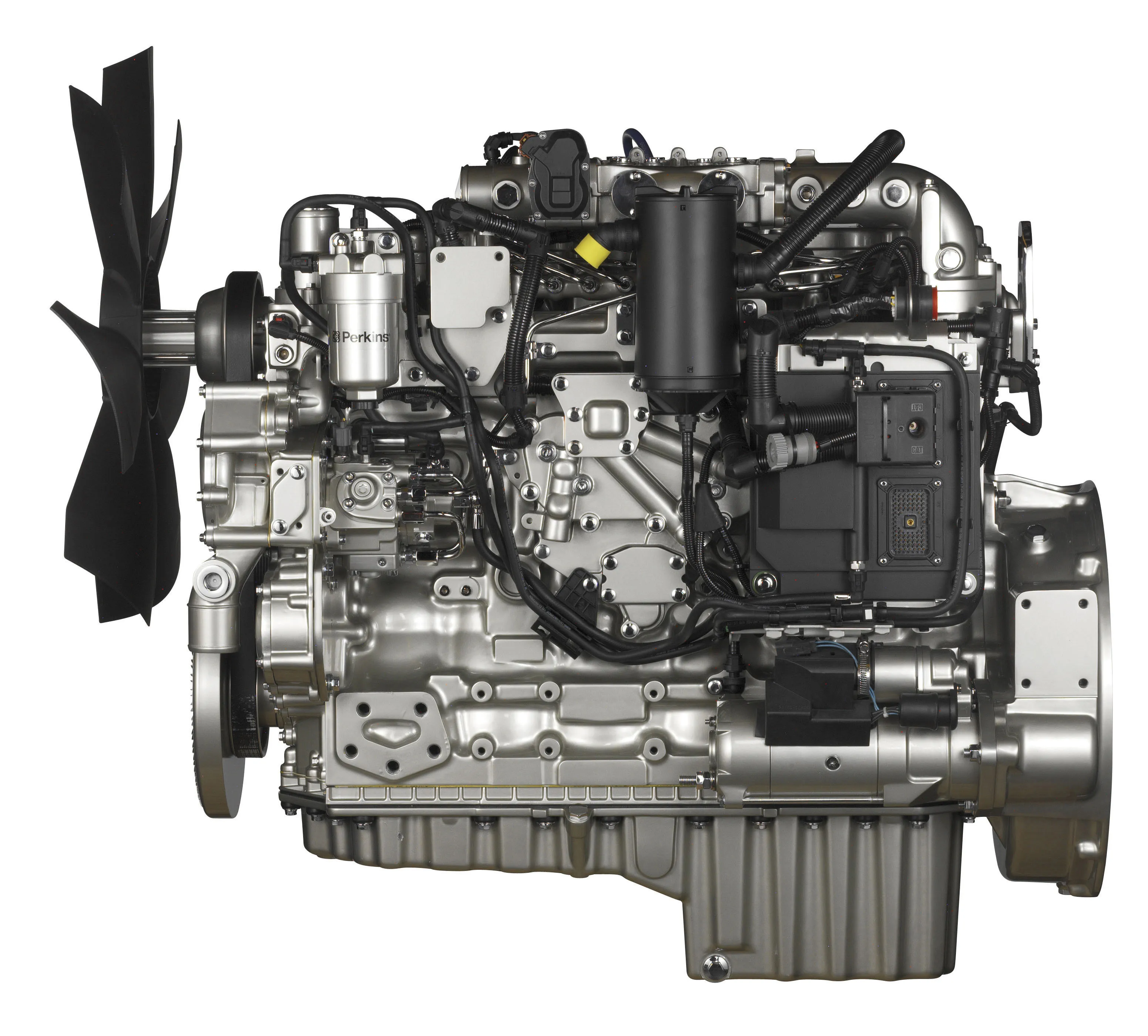

The SCRFilter system from Liebherr comprises a DOC catalytic converter, a SCR catalytic converter and a SCR-coated particulate filter. The DOC catalytic converter is maintenance-free and the coated particulate filter has passive regeneration, making the system reliable and easy to operate. The combustion process was optimised so that only a few particles arise that have to be held back by the SCRFilter. As a result, the maintenance intervals can be stretched to more than 4,500 operating hours. With the in-house development of engines, injection systems, engine controls and exhaust-gas-aftertreatment solutions Liebherr enables high system integration. High efficiency stage can be achieved with simultaneous low fuel consumption. As an all-in-one solution, the further developed ECU3 engine control unit comprises all control functions for engines up to 560 kW and also for exhaust-gas-aftertreatment.

The SCRFilter is part of the Liebherr modular system for engines and is compatible with all engines in the D93, D94 and D95 series. These engines have identical performances, machine cooling system requirements and the same interfaces during installation for the emission standards IIIA/ IV and stage V. It allows the customer to use the same machine design for various emission standards.